A vacuum cleaner for the textile industry

A technology for the textile industry and vacuum cleaners, applied in the field of vacuum cleaners in the textile industry, can solve the problems of slow suction speed, knotting, flocs flying poplars damage parts, etc., and achieves the effect of reducing air intake noise, increasing the jitter effect, and the flocs loosening and stabilizing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

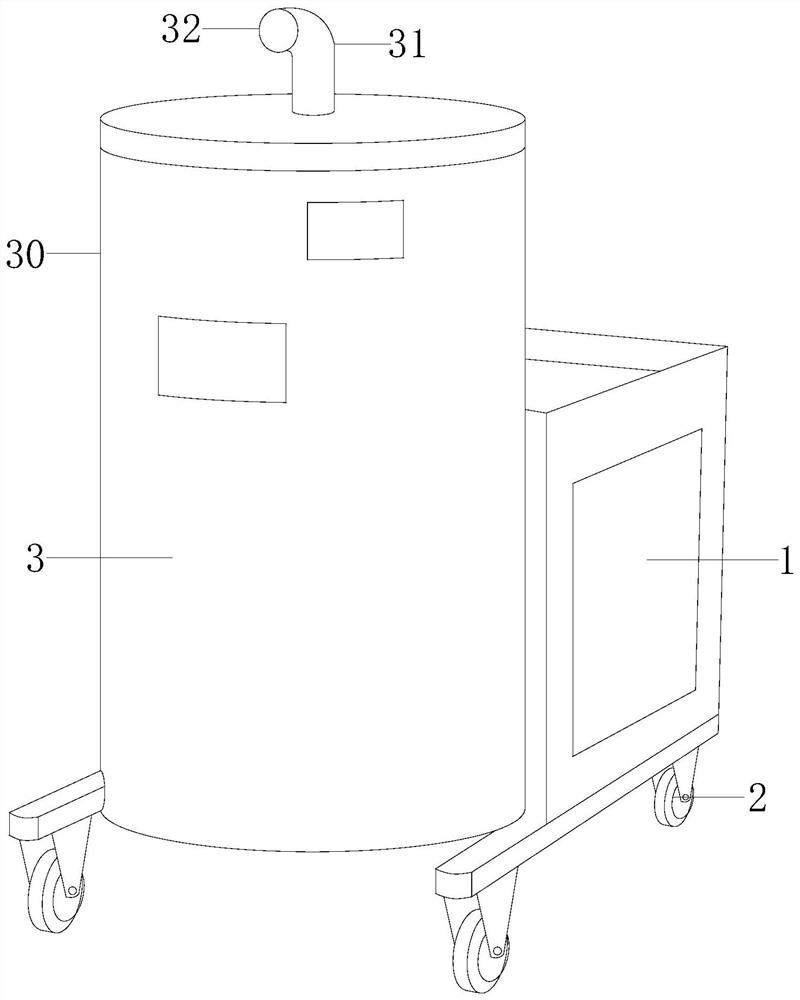

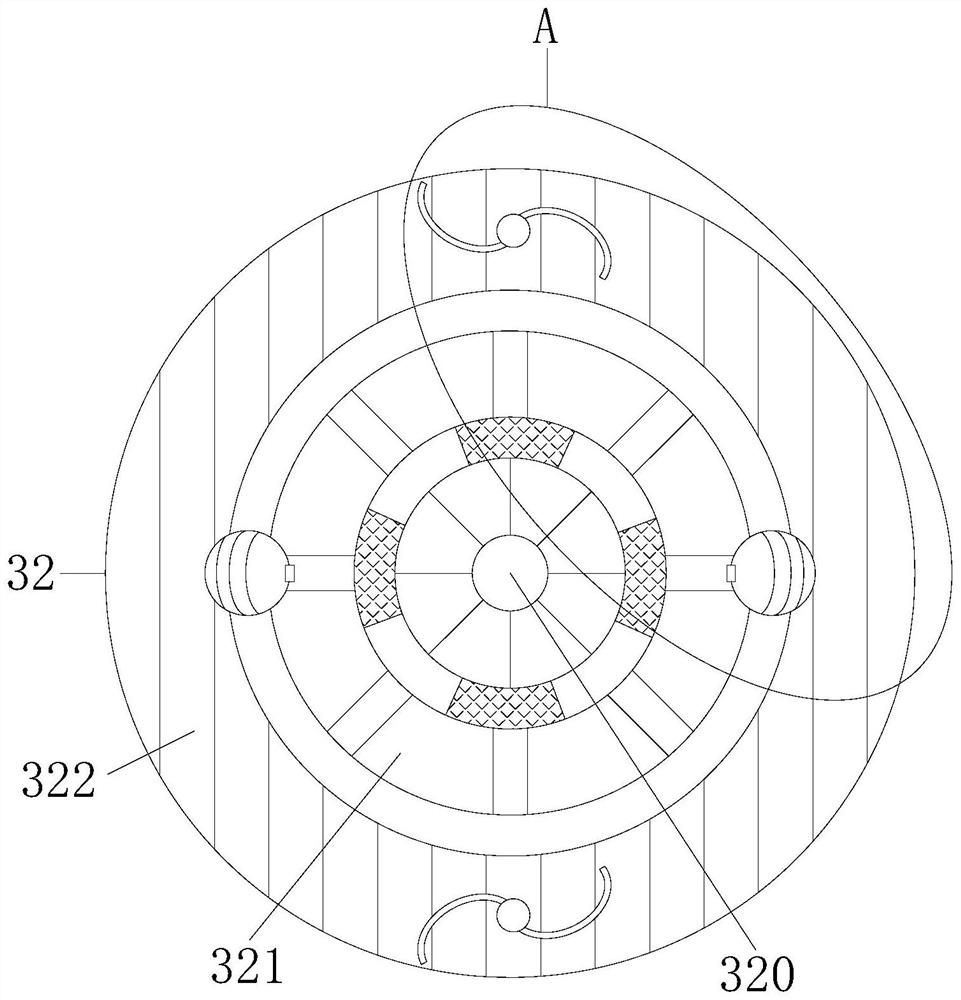

[0025] Example 1 see Figure 1-2 , the present invention provides a technical solution for a vacuum cleaner in the textile industry: its structure includes a chassis 1, a frame wheel 2, and a dust collection barrel 3, the chassis 1 and the frame wheel 2 are locked, and the chassis 1 and the dust collection barrel 3 are embedded, so The dust suction bucket 3 is arranged on the frame wheel 2, and the dust suction bucket 3 is composed of a cylinder body 30, a bobbin tube 31, and a nozzle structure 32. 32 is installed on the bobbin 31, and the flocs on the cleaning and collecting machine can be installed with the nozzle structure 32. After the nozzle structure 32 is removed, the diameter of the flocs collected will become larger, and the efficiency of the vacuum cleaner to collect the flocs on the ground will be improved. , the nozzle structure 32 includes a high-pressure air outlet structure 320, a middle ring stroke structure 321, and an outer ring soft wind structure 322. The ...

Embodiment 2

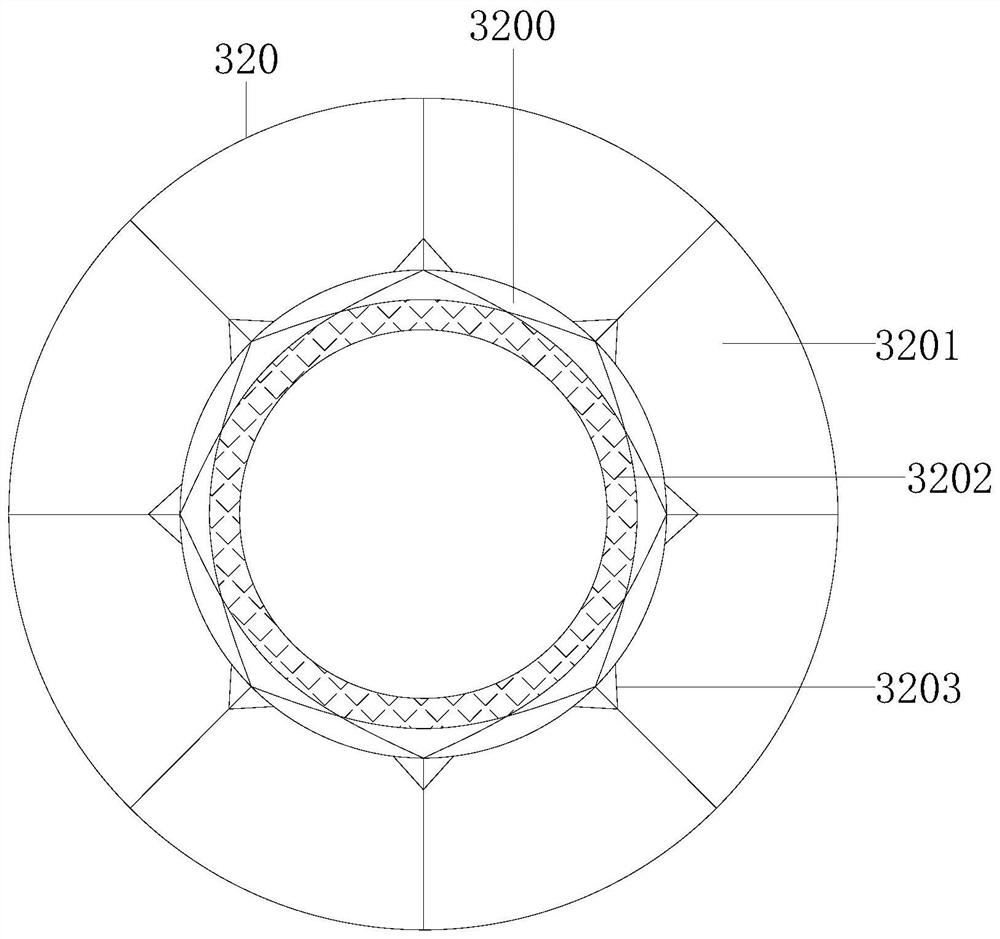

[0027] Example 2 see Figure 3-6, the present invention provides a technical solution for a vacuum cleaner in the textile industry: the structure of the high-pressure air outlet structure 320 includes a swivel 3200, a fixed plate 3201, a soft ring 3202, and a triangular clamp 3203, and the swivel 3200 is glued to the fixed plate 3201 , the triangular clamp 3203 is fixed on the swivel 3200 and the fixed plate 3201, the swivel 3200 is connected with the soft ring 3202, and the swivel 3200 is driven by variable diameter, which controls the spraying force and avoids scattered spraying , and also plays the role of fixing the soft ring 3202, the fixing plate 3201 is used to reinforce the high-pressure air outlet structure 320 as a whole, the triangular clamp 3203 is used to strengthen the installation position of the fixing plate 3201 and the swivel ring 3200, and the middle ring stroke structure 321 It includes an air inlet main ring 3210, a fixing strip 3211, an air inlet auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com