Delta robot drive-control system

A technology of robots and subsystems, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as low efficiency, low communication efficiency, and limited number of networkable robots, and achieve cost-effectiveness and increase computing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above objects, features and advantages of the present invention more obvious and understandable, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments,

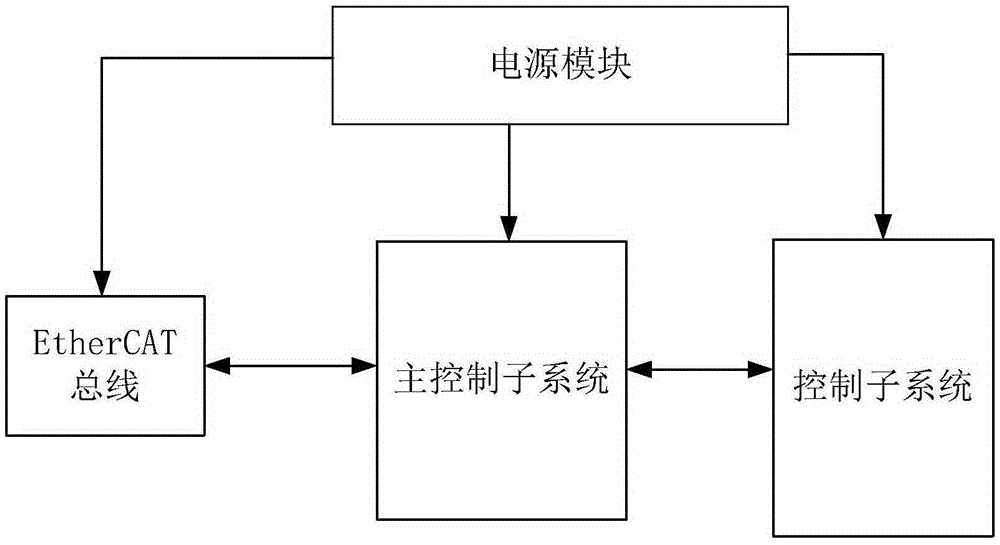

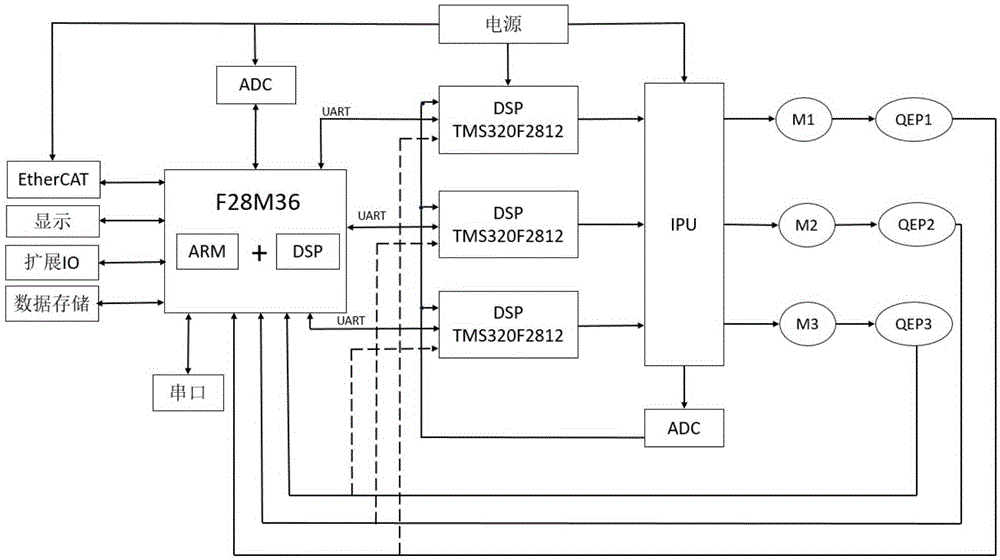

[0017] see figure 1 and figure 2 , the Delta robot drive control system of the present invention includes a main control subsystem, a control subsystem and a power supply module, the main control subsystem realizes robot dynamics calculation and closed-loop control, and the control subsystem realizes the control of the servo motor, so Two-way data cooperative transmission is performed between the main control subsystem and the control subsystem. The main control subsystem includes a F28M36 dual-core chip, and the F28M36 dual-core chip includes an ARM processor responsible for peripheral circuit monitoring and an ARM processor responsible for all calculations of the robot. DSP processor, the Delta r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com