Mobile phone shell processing technique, mobile phone shell and mobile phone

A mobile phone shell and processing technology, which is applied in the direction of telephone structure, telephone communication, electrical components, etc., can solve the problems of complex internal structure of mobile phone shell, unsuitable for large-scale batch processing, and inability to reduce the total cost of mobile phones, etc. The appearance is beautiful and generous, the production cycle is shortened, and the processing cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

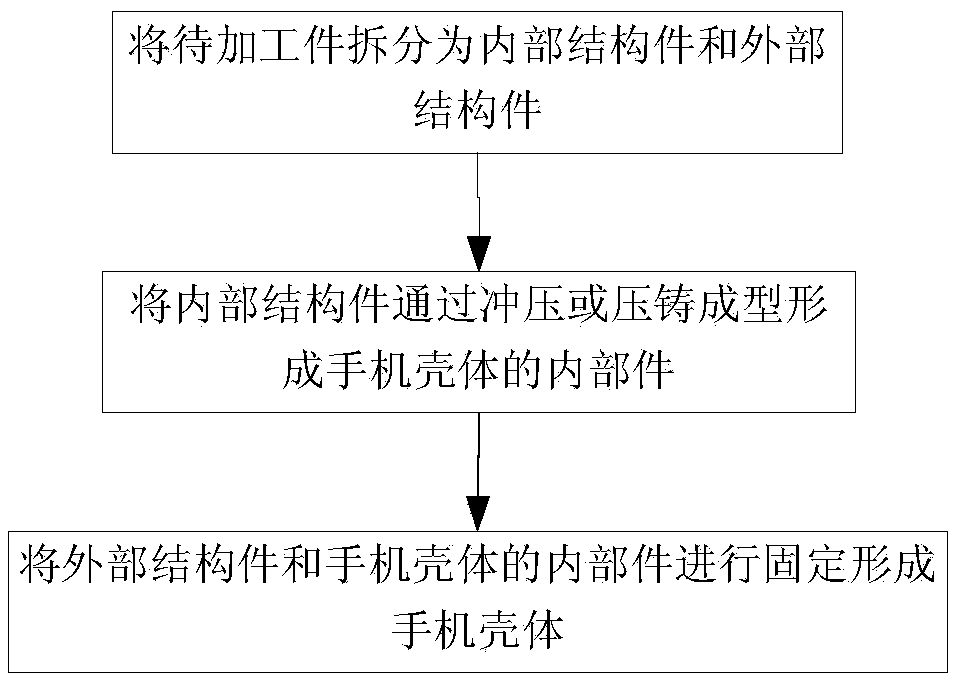

[0033] The preferred embodiment discloses a mobile phone casing processing technology. Such as figure 1 As shown, the mobile phone casing processing technology includes at least the following steps: splitting the workpiece to be processed into internal structural parts and external structural parts; forming the internal structural parts by stamping or die-casting to form the internal parts of the mobile phone casing; The parts and the internal parts of the mobile phone housing are fixed to form the mobile phone housing.

[0034] The mobile phone casing processing technology can improve the processing efficiency of the mobile phone casing, shorten the production cycle of the mobile phone casing, and reduce the processing cost, and solve the problem that the existing mobile phone casing processing technology needs to perform CNC processing on the internal structural parts, resulting in a long production cycle, The problem of high manufacturing costs.

Embodiment 2

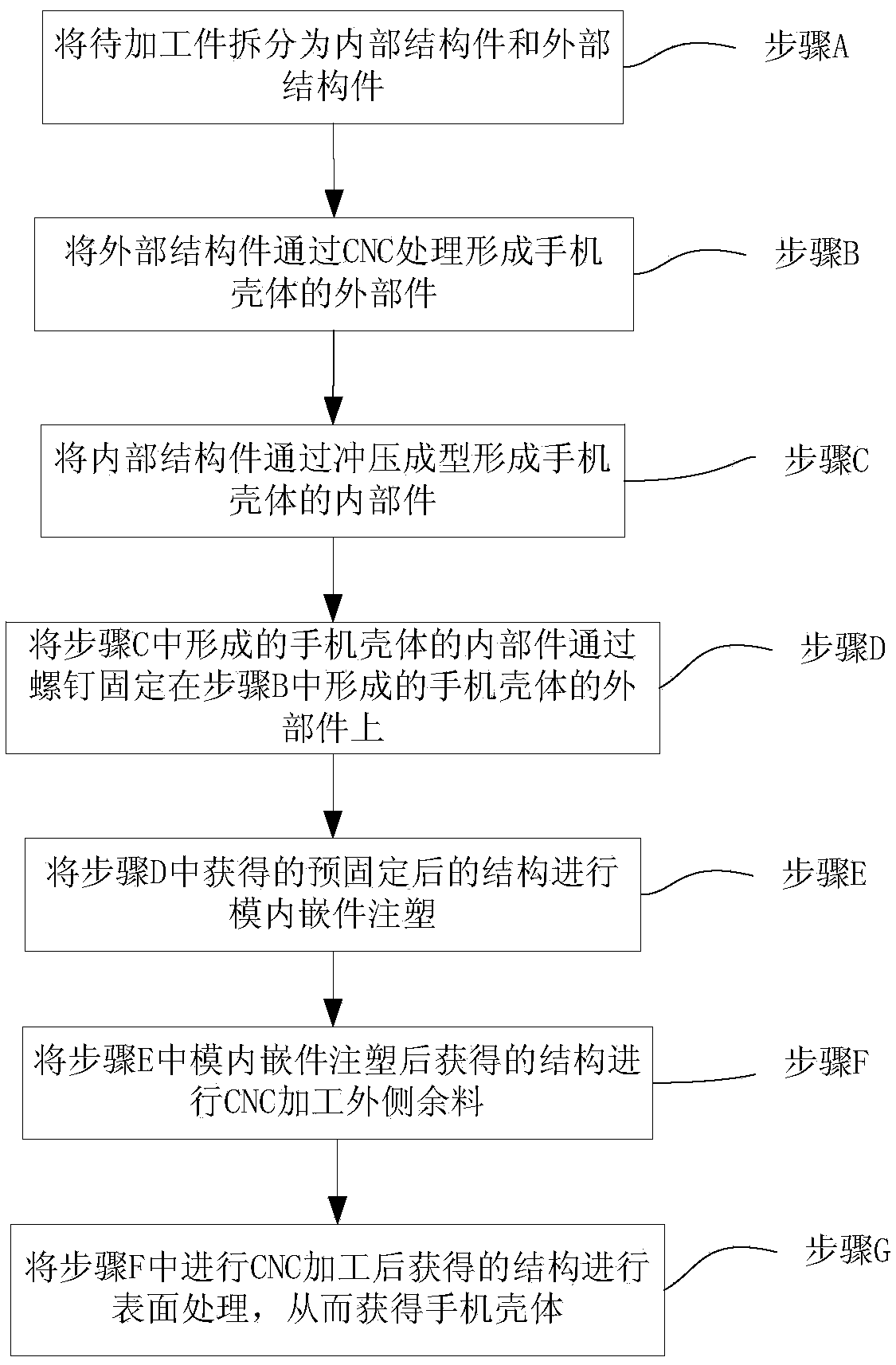

[0036] The preferred embodiment discloses a mobile phone casing processing technology. Such as figure 2 As shown, the mobile phone shell processing technology specifically includes the following steps:

[0037] Step A, splitting the workpiece to be processed into internal structural parts and external structural parts, wherein, the workpiece to be processed is preferably hardware, and can also be made of other materials, as long as it can meet the processing and use requirements. In this step, the The workpiece to be processed is divided into two parts to be processed separately, without affecting the processing efficiency and yield rate, and the processing is very convenient;

[0038] Step B, processing the external structural parts through CNC to form the external parts of the mobile phone housing;

[0039] Step C. The internal structural parts are formed into the internal parts of the mobile phone case by stamping. In this step, the internal parts of the mobile phone cas...

Embodiment 3

[0047] The preferred embodiment discloses a mobile phone casing processing technology. The mobile phone casing processing technology is basically the same as that of the preferred embodiment two, specifically comprising the following steps:

[0048] Step A, splitting the hardware parts to be processed into internal structural parts and external structural parts;

[0049] Step B, processing the external structural parts through CNC to form the external parts of the mobile phone housing;

[0050] Step C, the internal structural parts are formed by die-casting to form the internal parts of the mobile phone shell. This step uses die-casting to form the internal parts of the mobile phone shell, which greatly shortens the production cycle, reduces the processing workload, and replaces CNC (that is, numerically controlled Machine tool processing) processing, reduced costs, suitable for large-scale promotion and application;

[0051] Step D, pre-fixing the outer part of the mobile p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com