Stitching process equipment automatic device

A technology of equipment automation and lamination process, which is applied in printed circuit manufacturing, electrical components, printed circuits, etc., can solve the problems of low labor efficiency and equipment efficiency, boards cannot be operated at the same time, and the degree of automation is not high, so as to reduce personnel handling , Shorten the time of target shooting and stacking, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

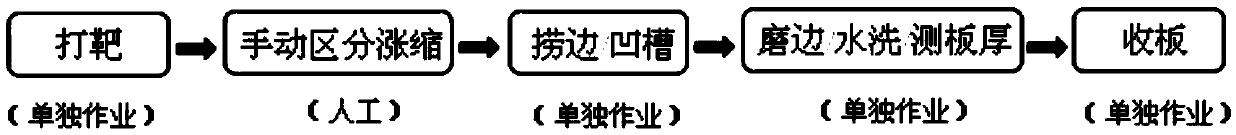

[0033] Such as figure 1 Shown is a schematic diagram of the operation flow of the traditional lamination process.

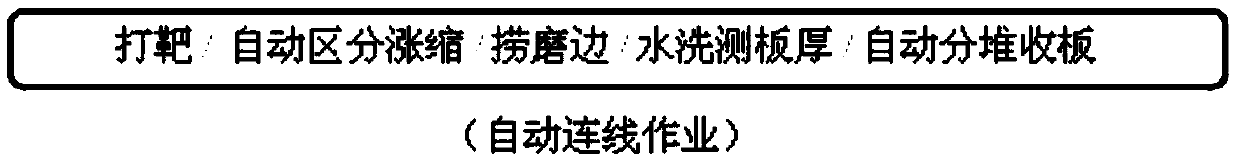

[0034] Such as figure 2 As shown, it is a schematic diagram of the operation flow of the lamination process equipment automation device disclosed in the present invention.

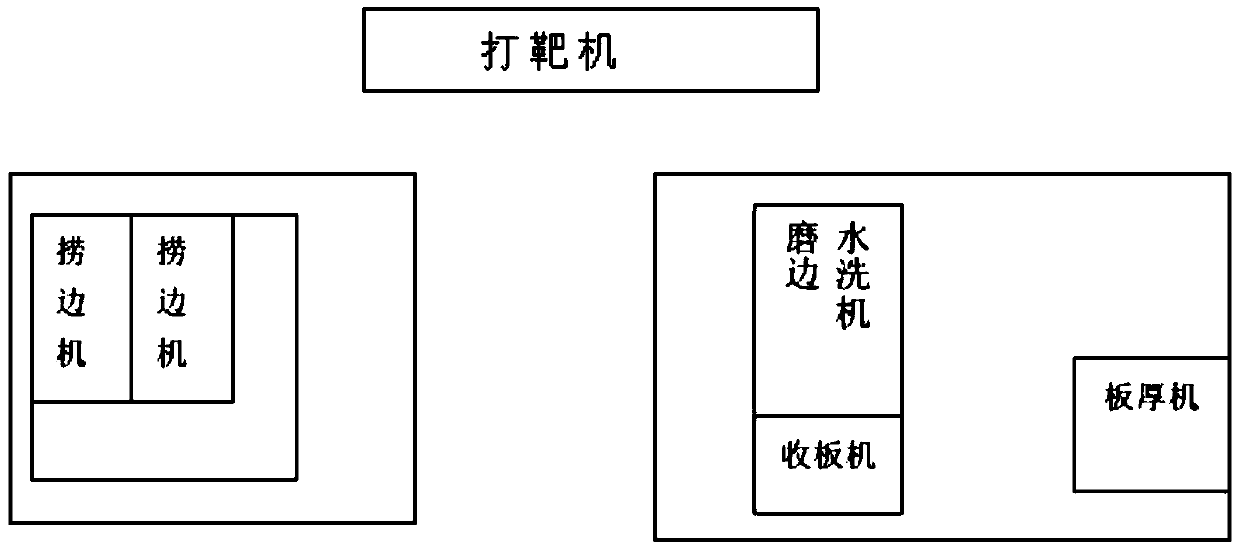

[0035] Such as image 3 It is a distribution map of the traditional lamination post-processing area. Different equipment is located in different space ranges, which wastes space, and cannot work continuously, wastes resources, and reduces production efficiency.

[0036] Such as Figure 4 It is the planning of the newly disclosed connection operation area in this city. The optimized planning of the connected operation area saves space, has a high degree of automation, is easy to operate, improves work efficiency, saves costs,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com