Adjustment base for clamping PCB

A technology of PCB board and adjustment base, applied in the direction of PCB socket, support structure installation, etc., can solve the problems of inability to adapt to different types and the size of the clamping base is not adjustable, and achieve the effect of preventing electrostatic breakdown and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

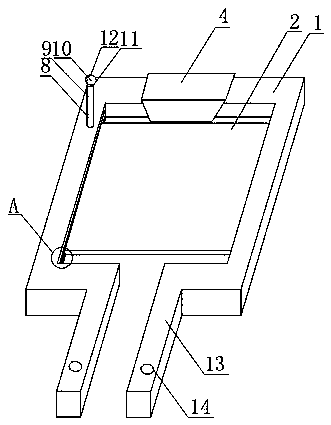

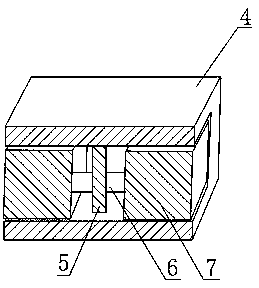

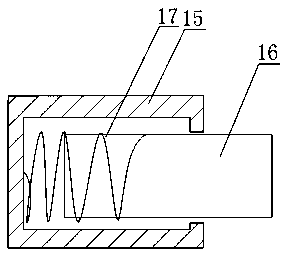

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the adjustment base for clamping the PCB board includes the frame frame 1 and the PCB board 2 clamped in the frame frame 1; the inner wall of the frame frame 1 is provided with a groove 3, and the two ends of the PCB board 2 respectively arranged in the grooves 3 on the left and right side walls of the frame frame 1; The sliding rod 7 connected with the fixed rod 5 through the elastic member 6; the frame frame 1 is provided with a winding column 8; the elastic member 6 includes a connecting rod 15 with an end opening as a cavity structure, and is slidably arranged on the connecting rod The adjusting rod 16 in 15 and the spring 17 connecting the adjusting rod 16 and the connecting rod 15, the adjusting rod 16 is sleeved in the spring 17, one end of the spring 17 is arranged at the bottom of the connecting rod 15, and the other end is arranged on the side of the adjusting rod 16 on the wall.

[0026] In th...

Embodiment 2

[0028] In this embodiment, on the basis of Embodiment 1, the winding post 8 includes a support rod 9 and a snap ring 10 fixed on the upper end of the support rod 9 . The snap ring 10 includes a lower snap ring 11 and an upper snap ring 12 with one end hinged to the lower snap ring 11 and the other end snapped to the lower snap ring 11 . The lower snap ring 11 is fixed on the upper end of the support rod 9 .

[0029] When the lines are to be collected, the upper snap ring 12 snapped to the lower snap ring 11 is opened, and the lines on the PCB 2 are placed in the snap ring 10 for fixing, so that the lines are arranged in an orderly direction toward the set direction. The lines on the PCB board 2 are neat and beautiful, and the heat dissipation of the PCB board 2 is also beneficial.

Embodiment 3

[0031] In this embodiment, on the basis of Embodiment 1 or Embodiment 2, one end of the frame 1 is open, and further includes extensions 13 respectively arranged on both sides of the opening, and threaded holes 14 are provided at the ends of the extensions 13 . The threaded hole 14 provided at the end of the extension section 13 is used to fix the entire frame 1 on the chassis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com