Fuel injection valve for internal combustion engine

A technology of fuel injection pumps and internal combustion engines, which is applied in the direction of fuel injection pumps, fuel injection devices, charging systems, etc., to achieve the effect of compact structure and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

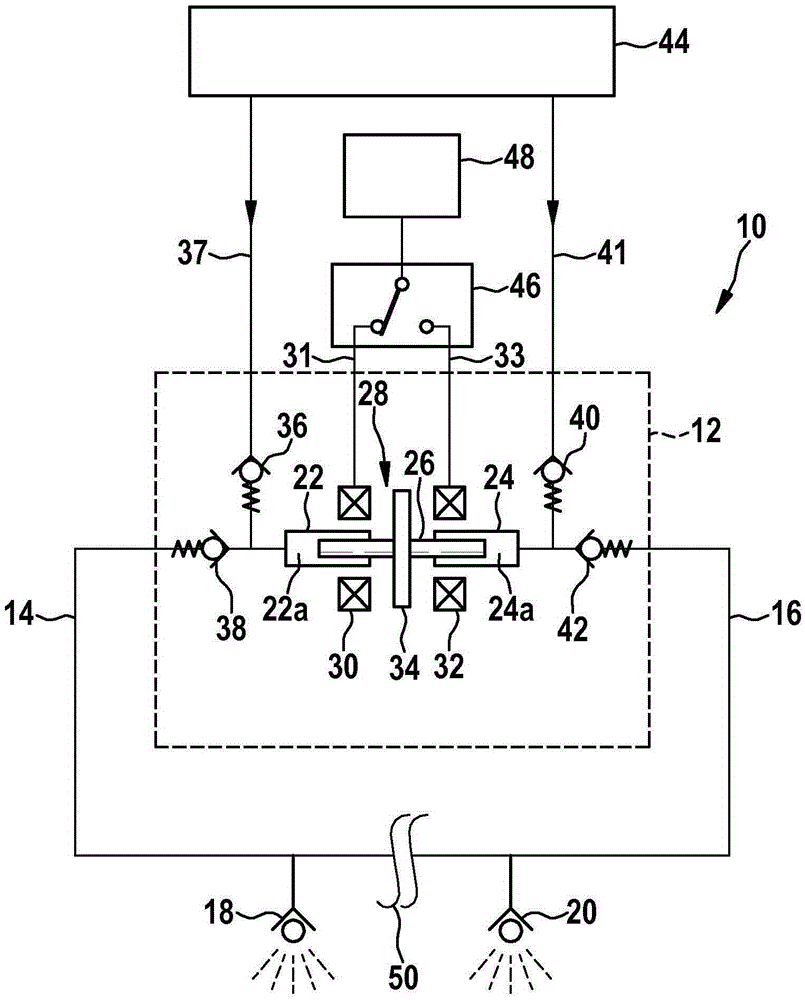

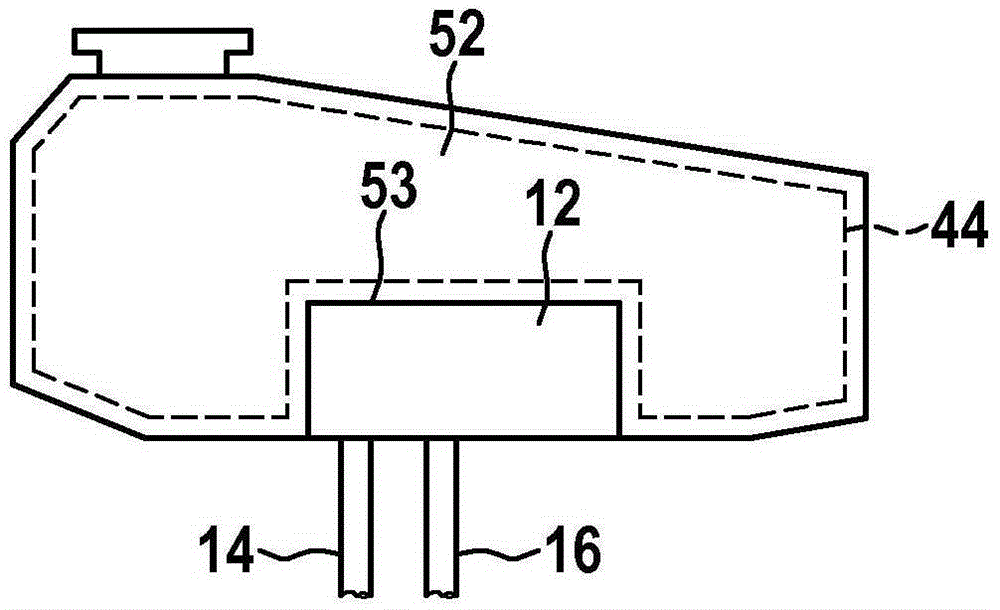

[0018] figure 1 A fuel system 10 for a two-cylinder internal combustion engine of a scooter (not shown), for example with a displacement of 50 ccm to 125 ccm, is shown schematically. The dotted box in the middle of the figure includes the fuel injection pump 12 embodied as a "dual stroke pump". The fuel injection pump 12 is now embodied symmetrically with respect to a vertical axis not shown in the drawing and is attached by means of fuel lines 14 and 16 to a first, pressure-controlled and outwardly opening injection valve 18 and a second injection valve, respectively. injection valve and 20 on. Second injection valve 20 is only required in the case of a two-cylinder internal combustion engine and is therefore optional.

[0019] The fuel injection pump 12 has a cylinder assembly with two cylinders 22 and 24 and a piston 26 movable axially therein (dual piston). The direction of movement of the piston 26 is figure 1 Medium is horizontal. A first axial end section of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com