Prefilter

A technology of pre-filter and filter part, which is applied in the field of water treatment, can solve problems such as complex internal structure, high manufacturing cost, and influence of water flow, and achieve the effects of simple structure, extended service life, and huge social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

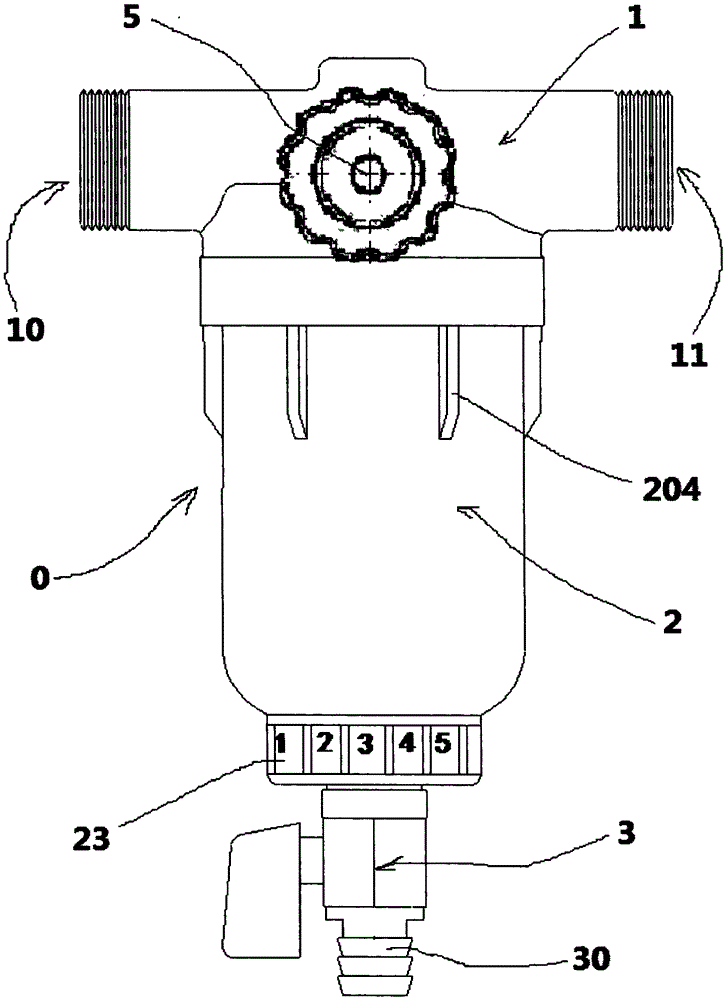

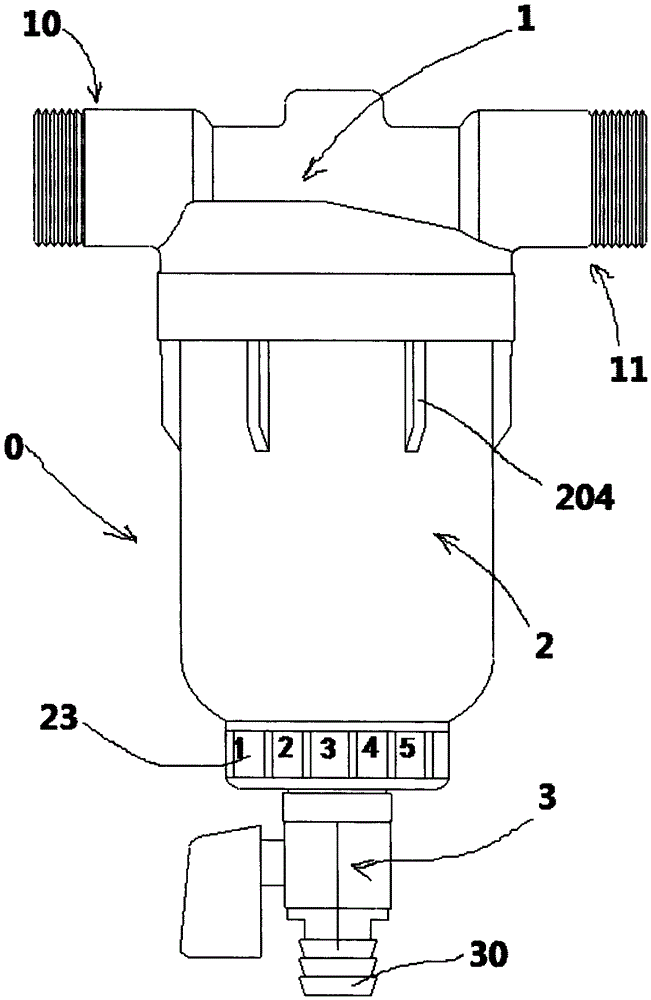

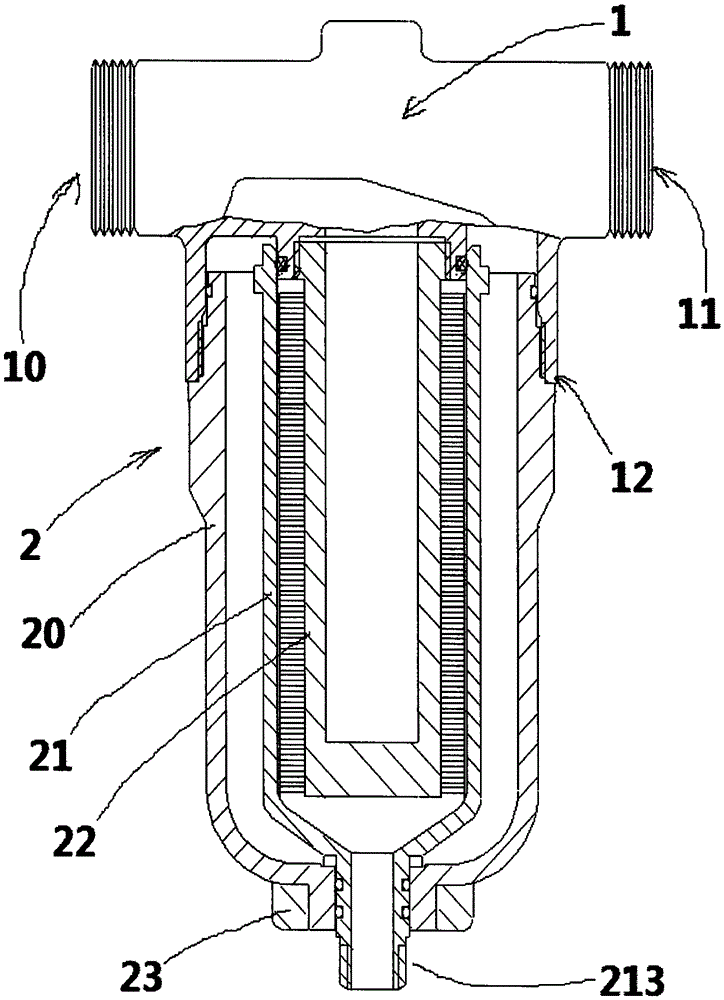

[0032] Such as figure 2 , image 3 , Figure 5 , Figure 6 , Figure 7 , Figure 9 and Figure 10As shown, a pre-filter includes a pre-filter body 0, the pre-filter body 0 is a connection part 1, a filter part 2, and a drain valve 3 from top to bottom in sequence, and one side of the connection part 1 is provided with The source water inlet 10 is provided with a filtered water outlet 11 on the other side corresponding to it, and the lower end port of the connecting part 1 is provided with a filter interface 12 and a filter element interface coaxial with the filter interface 12 in the lower end 13. The filter part 2 is sequentially composed of a filter part jacket 20, a filter element 21 and a scraping device 22 from the outside to the inside. The filter part jacket 20 is in the shape of a funnel with a large upper end and a smaller lower end. The upper end is a large port 200, and the lower end is a small port 201. , the large port 200 is connected to the filter interfa...

Embodiment 2

[0039] Such as figure 1 , Figure 4 , Figure 8 As shown, in this embodiment, there is a T-shaped three-way valve 5 inside the connecting part 1 , and the three ports of the T-shaped three-way valve 5 correspond to the source water inlet 10 , the filtered water outlet 11 and the filter element interface 13 respectively. Usually, a T-shaped three-way valve 5 is arranged inside the connecting part 1 to switch the direction of the water flow, so that the water flow reverses into the filter element 21 and realizes reverse flushing of impurities on the surface of the filter screen 211 . Others are similar to Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com