Prefilter

A pre-filter and filter cartridge technology, which is applied in the field of water treatment, can solve problems such as complex internal structure, high manufacturing cost, and influence of water flow, and achieve the effects of simple structure, extended service life, and huge social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

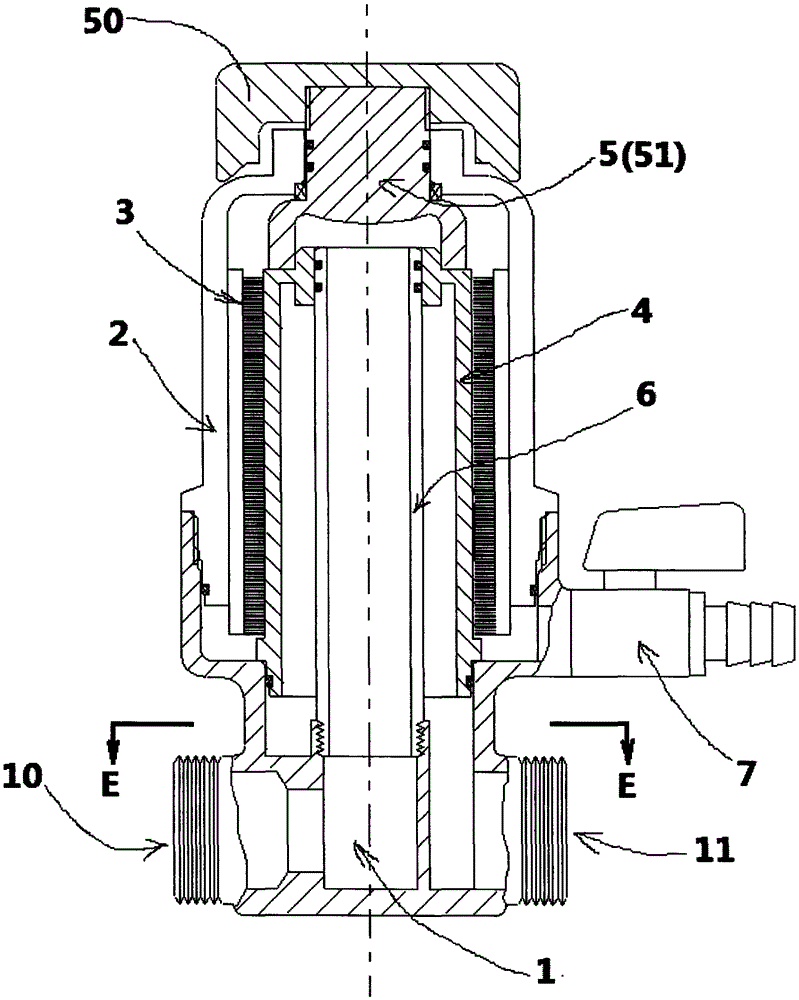

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, a pre-filter includes a connecting part 1 , a bottle body 2 , a flexible scraper strip 3 , a filter cartridge 4 , a rotating assembly 5 , a drainage tube 6 , and a drain valve 7 .

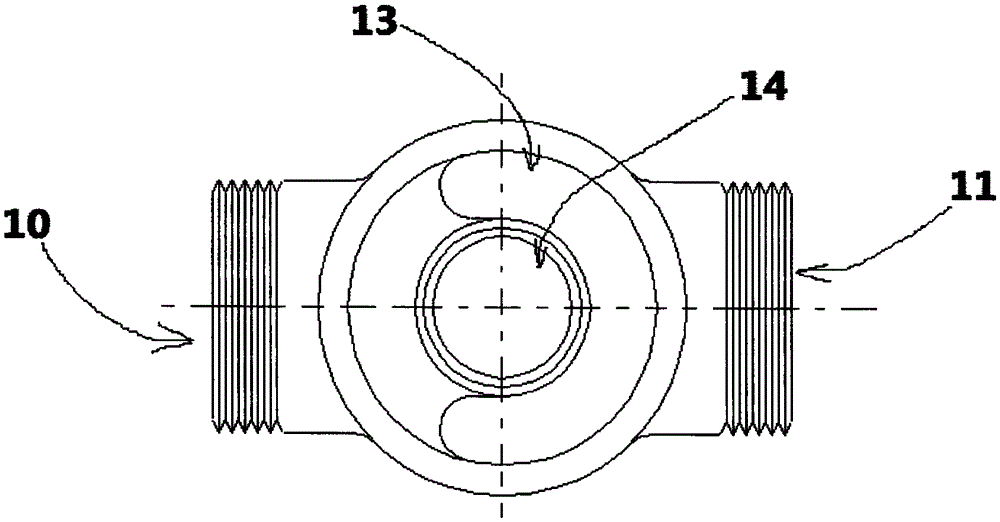

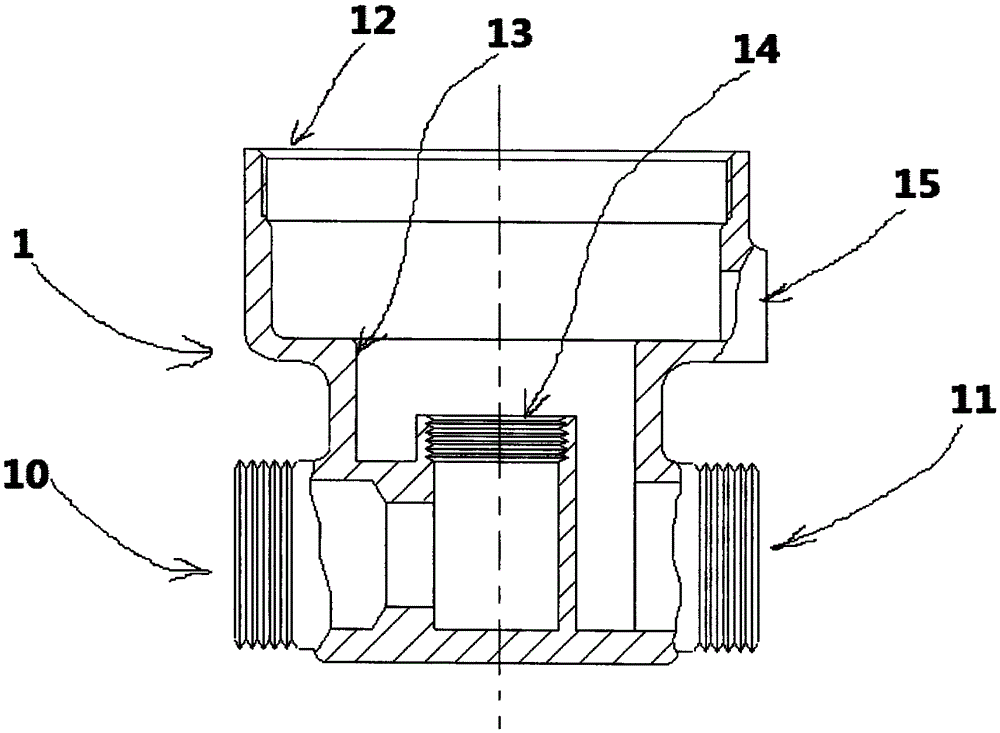

[0039] Such as image 3 As shown, the body of the connecting part 1 is provided with a water inlet 10, a water outlet 11, a bottle body interface 12, a filter cartridge interface 13, a drainage pipe interface 14 and a drain valve interface 15, a bottle body interface 12, a filter cartridge interface 13 and a drainage tube. The three interfaces 14 are located at the same axis from the outside to the inside and the openings are set in the same direction;

[0040] One end of the drainage tube 6 is fixedly connected to the drainage tube interface 14;

[0041] One end of the filter cartridge 4 is connected to the filter cartridge interfac...

Embodiment 2

[0051] Such as figure 2 , image 3 , Figure 4 , Figure 7 , Figure 8 , Figure 9 , Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, a pre-filter includes a connecting part 1 , a bottle body 2 , a flexible scraper strip 3 , a filter cartridge 4 , a rotating assembly 5 , a drainage tube 6 , and a drain valve 7 .

[0052] Such as image 3 As shown, the body of the connecting part 1 is provided with a water inlet 10, a water outlet 11, a bottle body interface 12, a filter cartridge interface 13, a drainage pipe interface 14 and a drain valve interface 15, a bottle body interface 12, a filter cartridge interface 13 and a drainage tube. The three interfaces 14 are located at the same axis from the outside to the inside and the openings are set in the same direction;

[0053] One end of the drainage tube 6 is fixedly connected to the drainage tube interface 14;

[0054] One end of the filter cartridge 4 is connected to the filter cartridge interface 13, and...

Embodiment 3

[0065] Such as Figure 15 As shown, a three-way valve 9 is also provided in the connecting part 1, and the three ports of the three-way valve 9 correspond to the water inlet 10, the water outlet 11 and the drainage pipe interface 14 on the connecting part 1 respectively, and the water flow is adjusted through the three-way valve 9 The direction can achieve that the water flow can flow out from the drainage pipe 6, and can also communicate with the water outlet 11 and enter the inner cavity of the filter cartridge 4, forming a backwash decontamination mode.

[0066] In this embodiment, others are similar to those described in Embodiment 1 or Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com