Railway ballast hopper car with ballast troweling function

A hopper car and flat ballast technology, which is applied to hopper cars, railway car body parts, roads, etc., can solve the problems of high accumulation of ballast, ballast without shaping, and derailment of vehicles, so as to ensure operation safety and improve operation Efficiency, the effect of avoiding vehicle derailment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the drawings and embodiments.

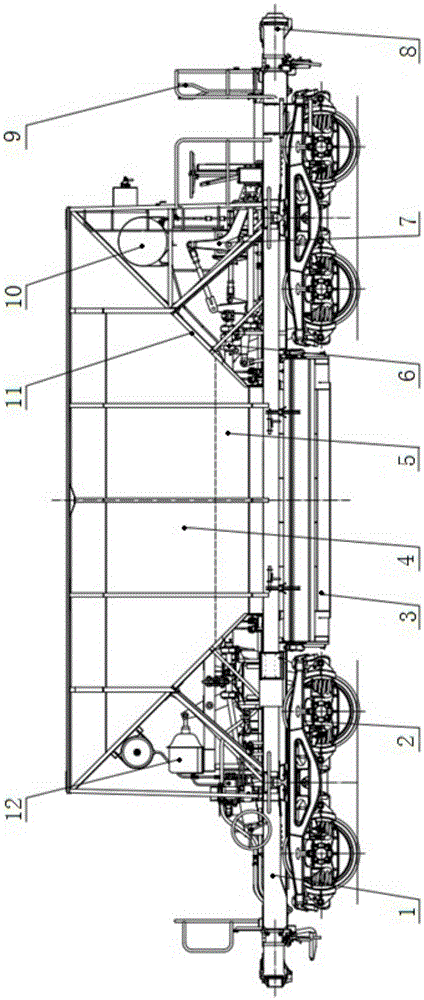

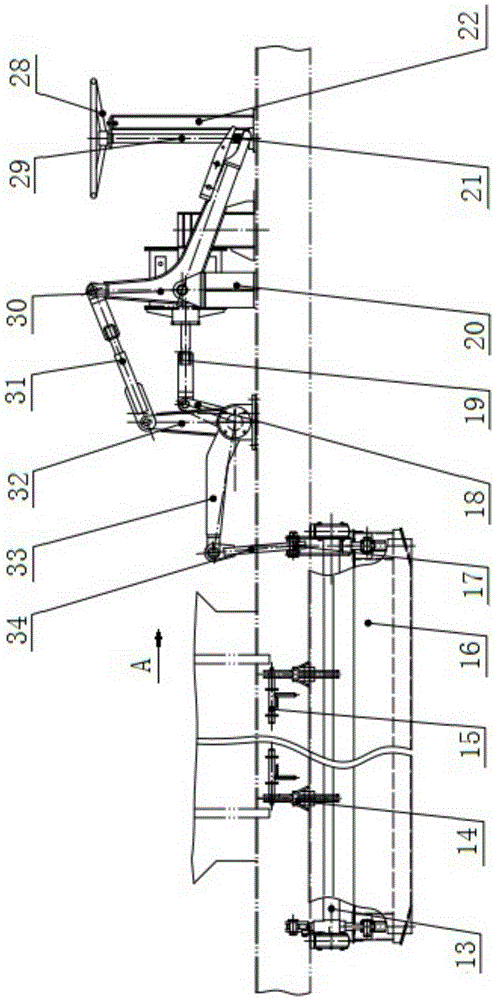

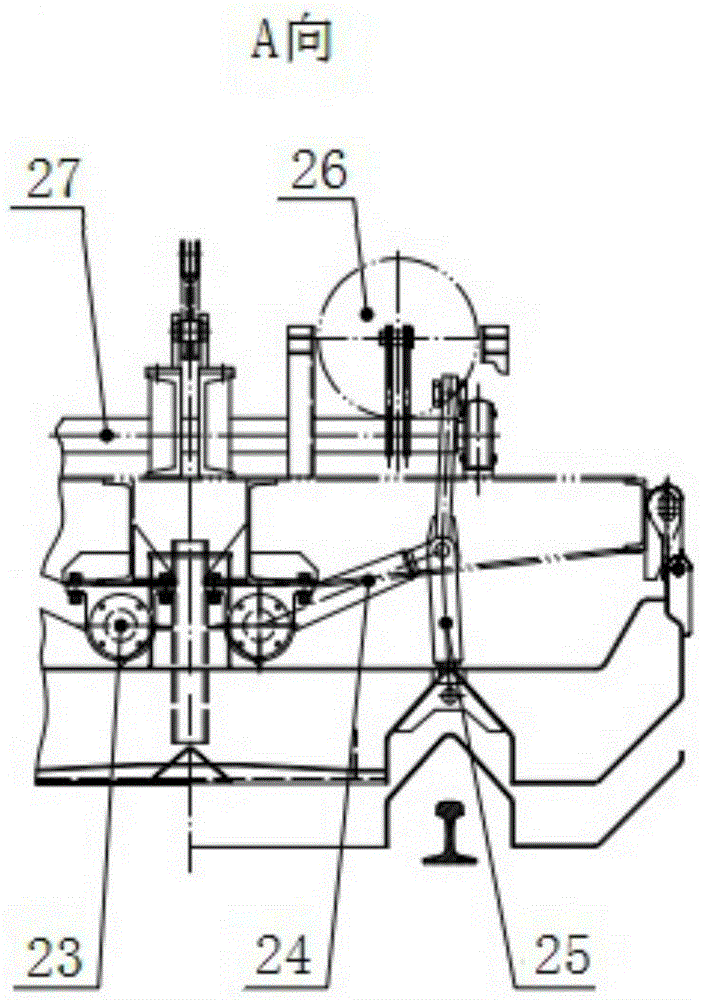

[0029] figure 1 Shown is a schematic diagram of the structure of the present invention.

[0030] The invention includes a car body, a ballast unloading device, a bottom door composition 6, a flat ballast system 7, a wind control system 10, a braking device 12, a coupler buffer device 8 and a bogie 2. The car body includes an underframe composition 1, a side The wall 4, the end wall 11, the funnel 5 and the ballast plate composition 3, and the ballast plate composition 3 is arranged below the funnel 5.

[0031] The wind control system 10 includes three two-way air cylinders, three control valves and a wind control pipeline. The two-way air cylinders are connected to the control valve through the wind control pipeline. Two of the three two-way air cylinders and the three control valves control The bottom doors on the left and right sides of the ballast unloading device are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com