Measurement device for off tracking of conveying belt of belt conveyor

A belt conveyor, measuring device technology, applied in the direction of conveyor control device, measuring device, conveyor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

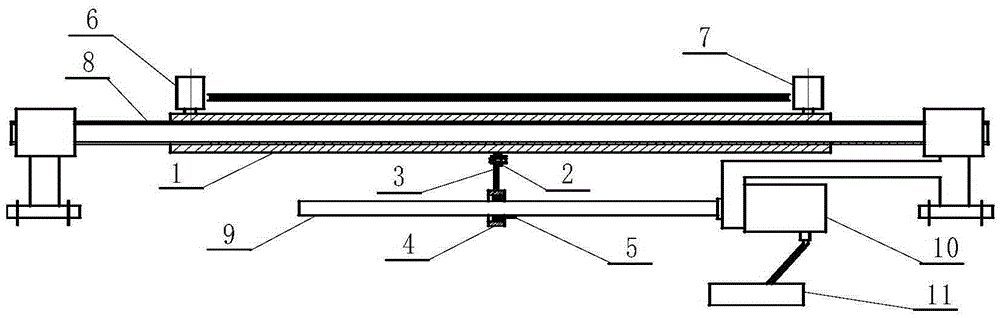

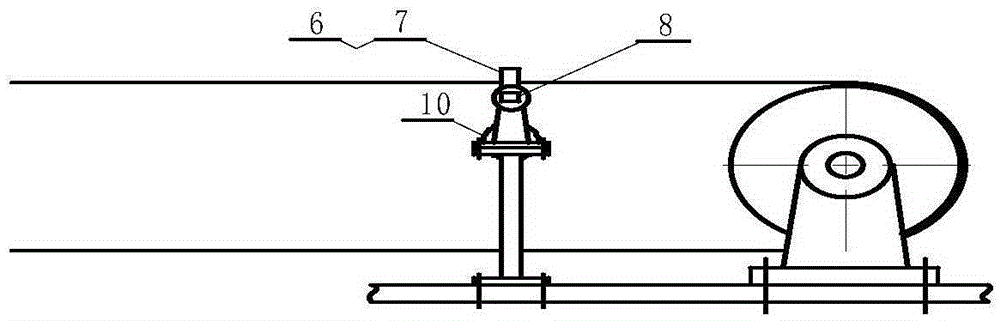

[0024] The invention discloses an application of a conveyor belt deviation measuring device of a belt conveyor to a large-scale belt conveyor.

[0025] 1. Installation:

[0026] A belt deviation measuring device for a belt conveyor according to the attached figure 1 And attached figure 2 , the whole device is installed under the conveyor belt in front of the belt conveyor tensioning roller, the magnetostrictive sensor 9 and the transmitter 10 are installed directly under the bracket 1, and the conveyor belt is clamped between the left vertical roller 6 and the right vertical roller In the middle of 7, the entire device is fixed on the structure of the belt conveyor with a bracket, the output signal of the transmitter 10 is connected to the smart meter 11, and the smart meter 11 is installed on the control cabinet of the belt conveyor. The magnetostrictive sensor 9 and the transmitter 10 are integrated with explosion-proof performance, the output signal is 4-20mA, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com