FRP (fiber reinforced plastic) tendon-bundle hybrid sling structure with warning function

A technology of steel beams and slings, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of bridge structure damage, the fatigue life of sling structures is difficult to predict, and the service life of sling structures is difficult to predict, so as to ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

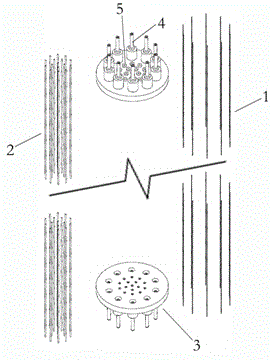

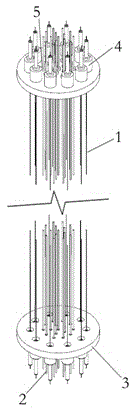

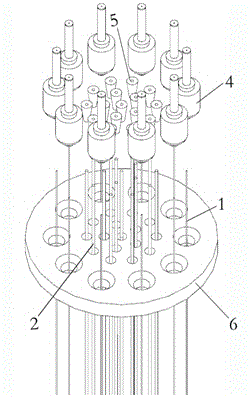

[0025] The FRP tendon-steel tendon combined sling structure with early warning function of the present invention includes FRP tendon 1, steel tendon 2 and composite clip anchor 3. The cable body of the sling structure is composed of tension rods made of FRP tendons 1 and steel tendons 2, the steel tendons are located in the inner area of the sling, and the FRP tendons are located in the peripheral area of the sling; the FRP tendons 1 pass through the FRP The special anchor piece 4 for the tendon is anchored on the composite clip anchor 3, and the steel beam 2 is anchored on the composite clip anchor 3 through the steel beam anchor 5.

[0026] The FRP tendon-steel beam combined sling structure with early warning function of the present invention includes all combined sling structures using FRP tendon 1 and steel beam 2, for those of ordinary skill in the art, without departing from the present invention Under the premise of the principle, some improvements and equivalent re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com