Natural gas plant station operation management system

An operation management system, natural gas technology, applied in the field of natural gas station management system, can solve the problems of lack of scientific, reasonable, transparent, real-time monitoring management and performance appraisal methods, etc., achieve rapid statistics and analysis, improve work efficiency, ensure The effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

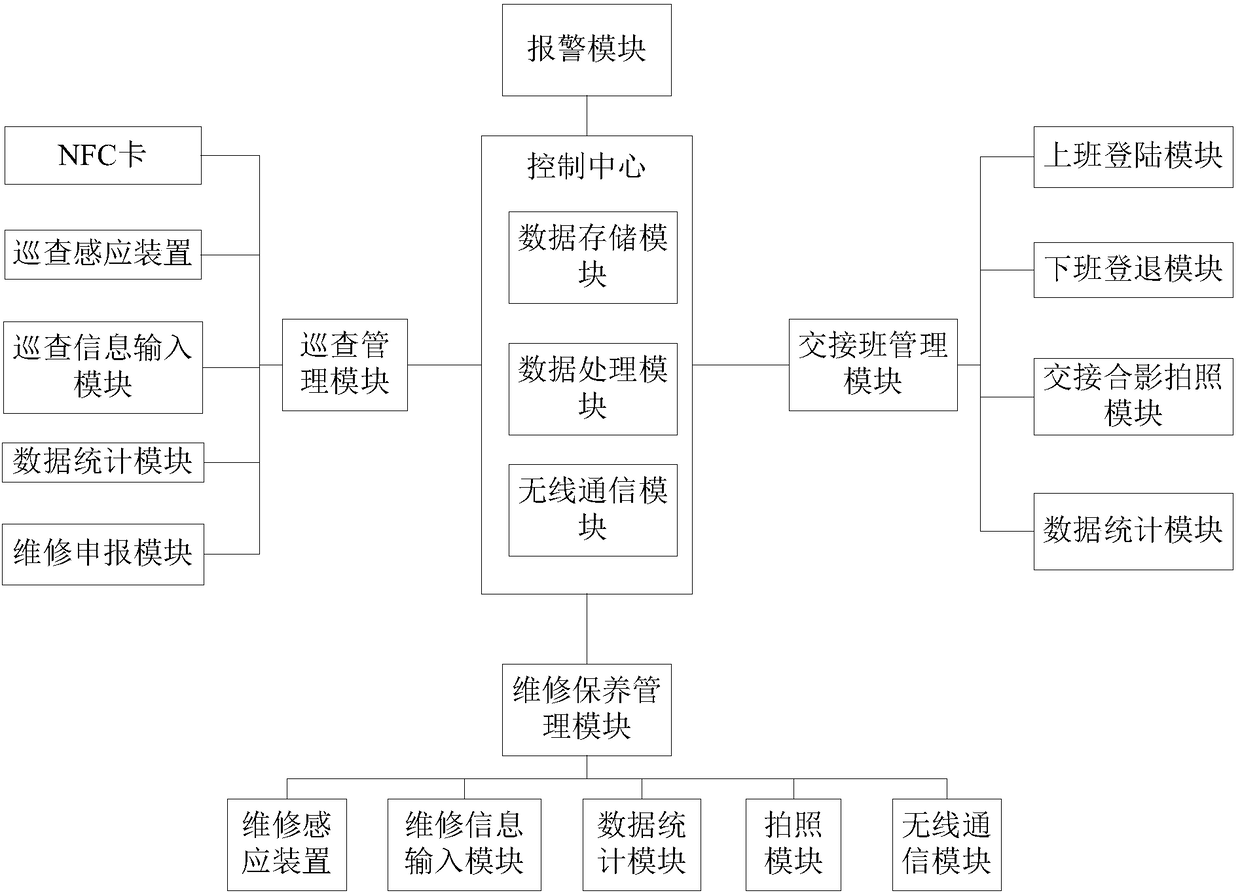

[0015] Please refer to figure 1 , This embodiment is a natural gas plant station operation management system, which includes a control center, a shift management module for data transmission with the control center, an inspection management module, a maintenance management module, and an alarm module.

[0016] The control center includes a data storage module, a data processing module, and a wireless communication module, and the data storage module includes the node data of working hours and the early warning value data of each equipment parameter.

[0017] The shift management module includes an on-duty log-in module, an off-duty log-in and log-out module, a handover photo taking module, a shift handover inspection situation input module, and a data statistics module. The on-duty log-in module uploads the employee information and the on-duty log-in time to the data storage module; the off-get off work log-out module uploads the off-get off work log-out employee information a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com