Yarn winding device

A winding device and yarn technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of longer yarn and longer time spent on jointing, etc., to achieve length suppression and shortening the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

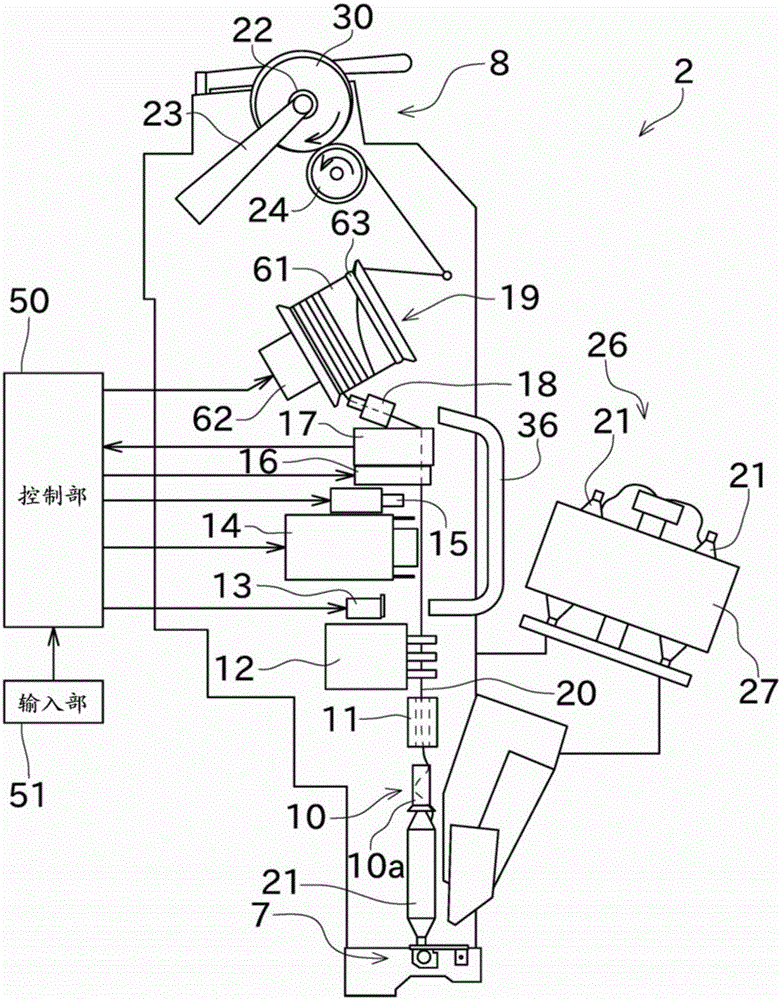

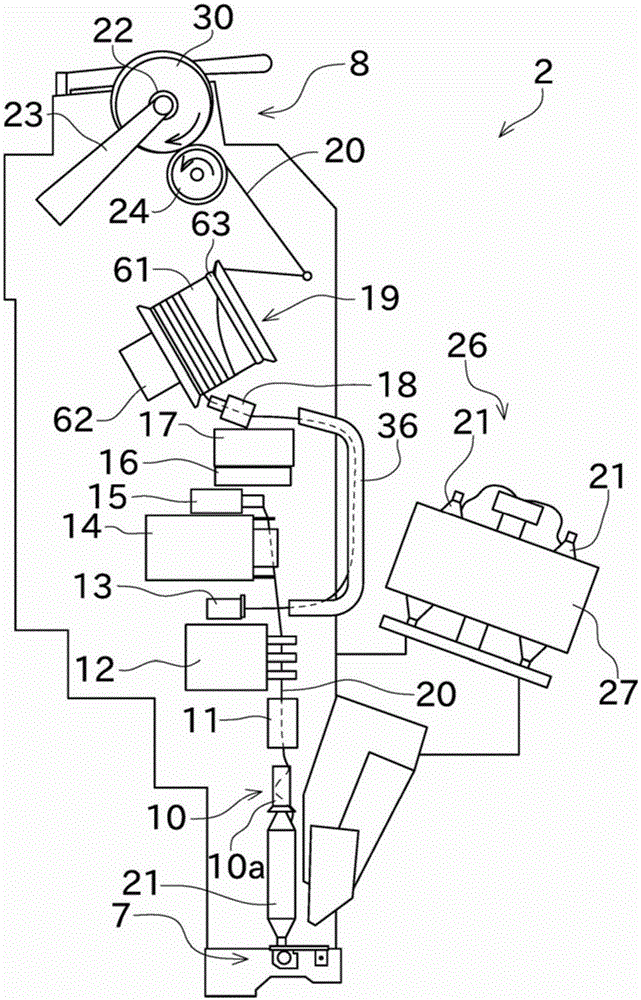

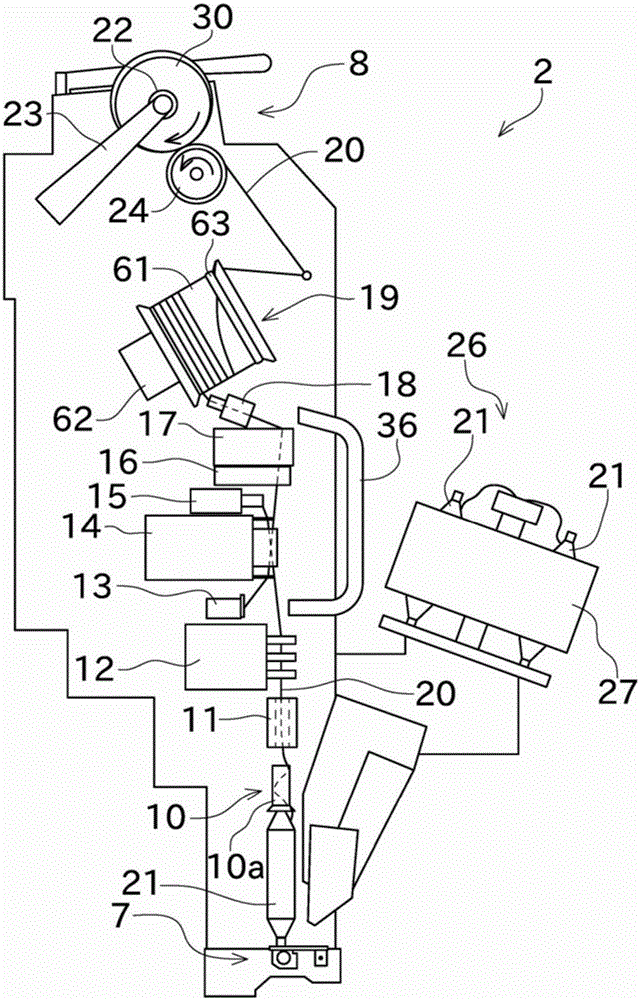

[0034] Next, embodiments of the present invention will be described. First, refer to figure 1 The outline of the automatic winder (yarn winding device) will be described. The automatic winder has a structure in which a plurality of winder units 2 are arranged in parallel. In addition, this automatic winder includes a body management device (not shown in the figure) for collectively managing the winder unit 2, and a blower box (not shown in the figure) provided with a compressed air source and a negative pressure source.

[0035] like figure 1As shown, the winding unit 2 mainly includes a control unit 50 , a yarn supplying bobbin support unit (yarn supplying unit) 7 , and a winding unit (package forming unit) 8 . The winding unit 2 is configured to unwind the yarn (spun yarn) 20 supported by the yarn supplying bobbin 21 supported by the yarn supplying bobbin support portion 7 and wind it back into the package 30 . In addition, in the following description, the upstream side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com