Device and method for storing heat for heat consumption parts in beverage preparation equipment

A beverage preparation and heat storage technology, applied in biochemical equipment and methods, heat storage equipment, heat exchange equipment, etc., can solve problems such as unavailability, heat flow of heat-consuming parts, insufficient heat, and inability to ensure heating speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

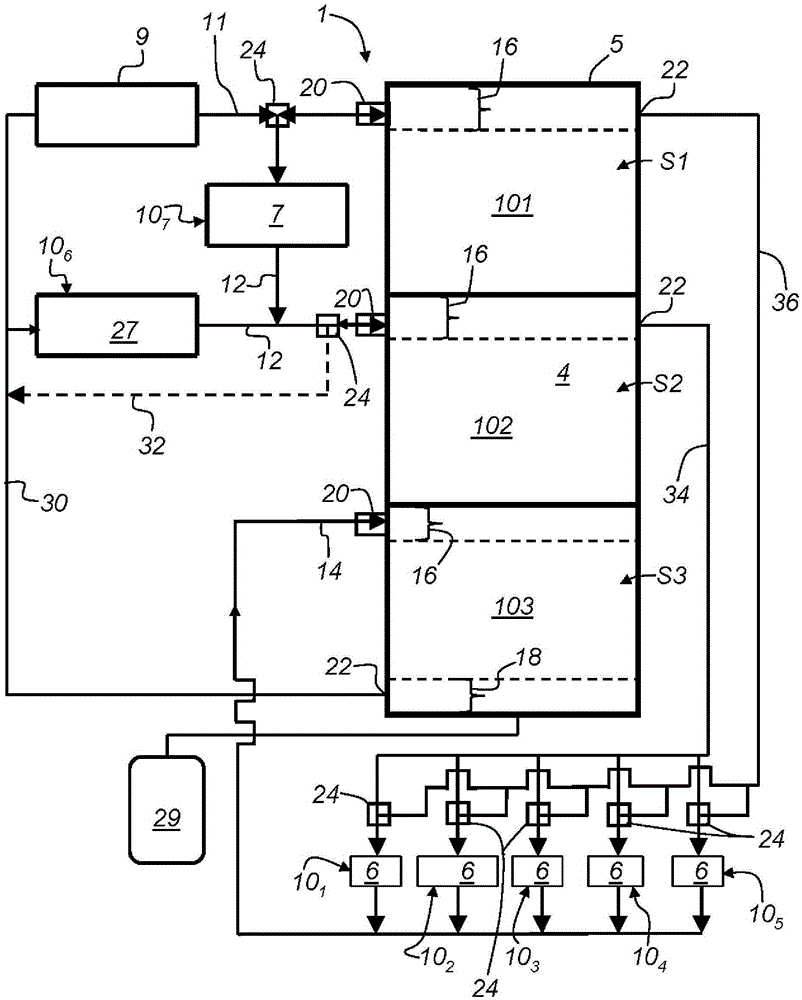

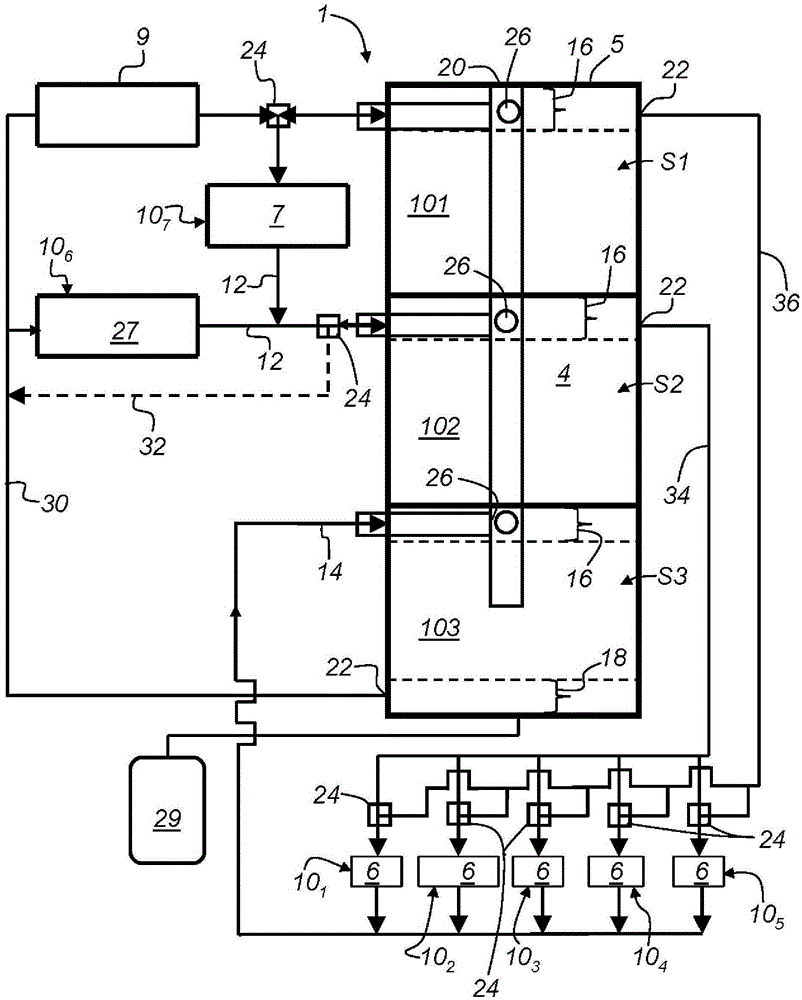

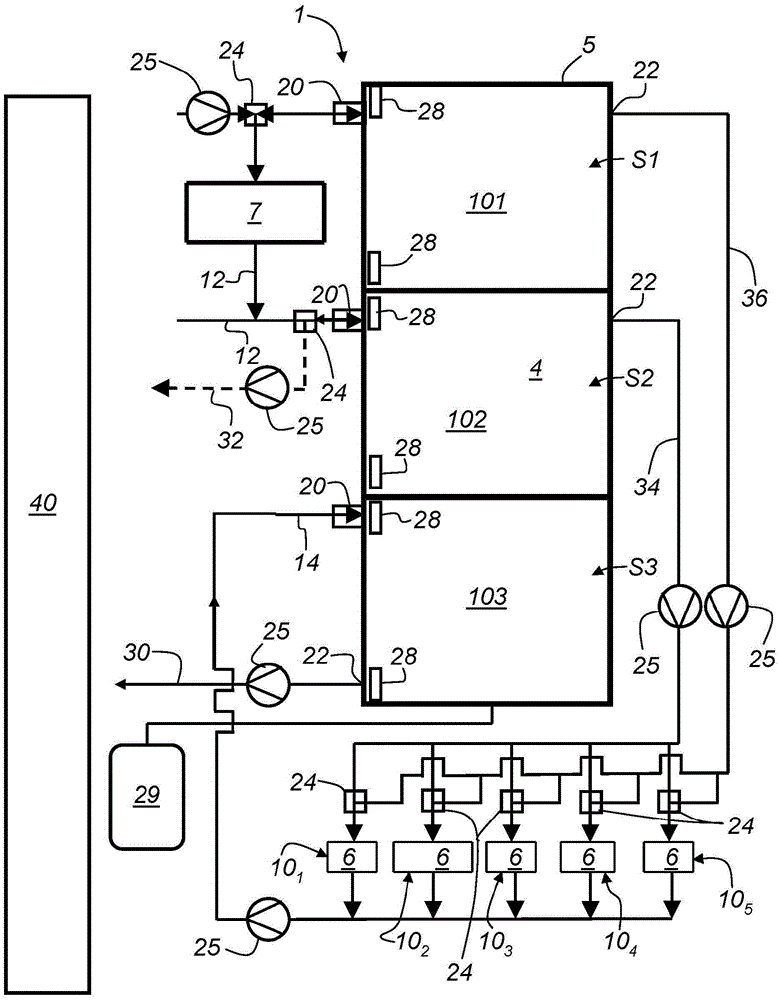

[0063] figure 1 An embodiment of a device 1 for heat storage in a beverage preparation appliance according to the invention is shown. The device 1 has a heat store 5 . Also be provided with a plurality of heat consumption components 10 1 、10 2 、10 3 ,...,10 N , these heat consumers are connected to a thermal storage 5 for the supply and / or extraction of thermal energy. Preferably the storage medium 4 is water. The storage medium 4 is stored in a plurality of layers S1 , S2 , S3 , . Although in figure 1 In the illustrated embodiment only three layers S1 , S2 and S3 are shown, but this is not to be understood as a limitation of the invention. Likewise between the layers S1 and S2, and between S2 and S3, separation lines are drawn, which only represent the delimitation of the individual layers S1, S2 and S3. These separation lines are not to be understood as fixed mechanical boundaries between the individual layers S1 , S2 and S3 . These separation lines mean that there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com