Movable drilling guiding and positioning device and drilling guiding and positioning method

A guiding positioning and mobile technology, which is applied in the direction of earth mover/excavator, construction, etc., can solve the problems that the steel cage cannot be translated in place, the scheme of one slot and two cages cannot be implemented, and the pipeline cannot be slotted, etc., to achieve the solution Problems in connecting wall construction, avoiding incomplete drilling, and avoiding the effect of relocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below in conjunction with accompanying drawing and embodiment:

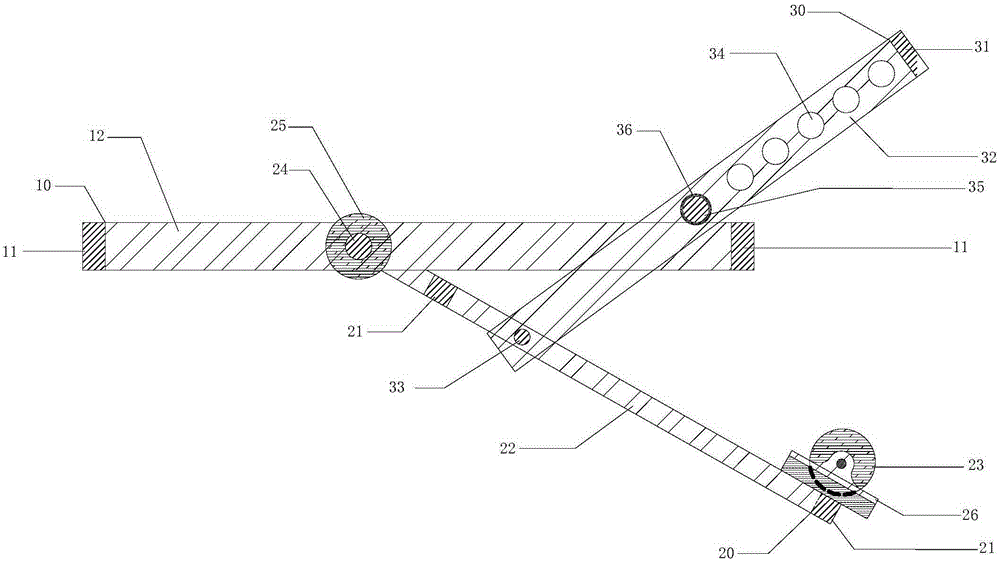

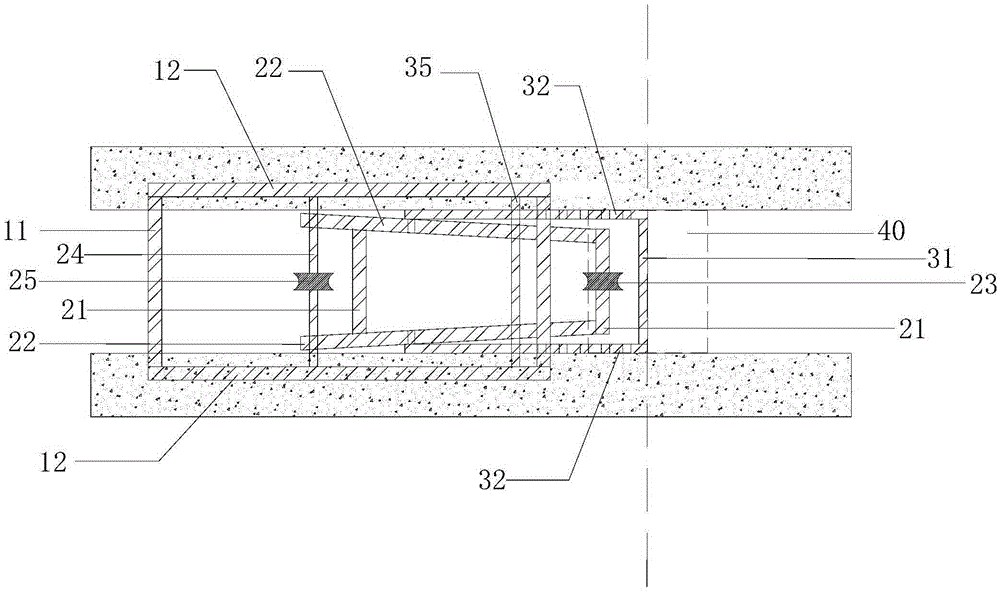

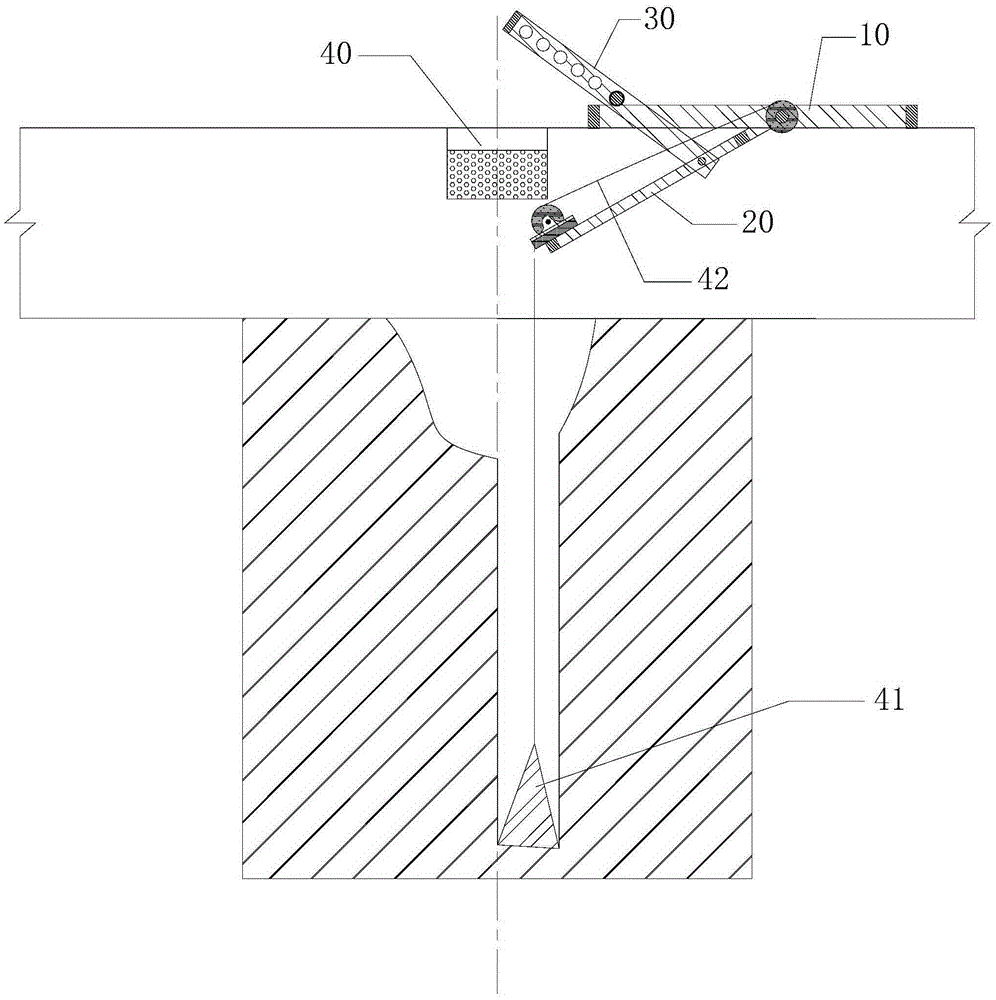

[0032] like figure 1 As shown, a mobile drilling guide positioning device includes a base bracket 10, a first positioning bracket 20 and a second positioning bracket 30,

[0033] The base support 10 adopts a frame structure, and the two base flat sides 11 are respectively connected to the two ends of the two base side vertical sides 12, and the two base side vertical sides 12 are provided with a number of symmetrical base positioning holes. Among them, the bottom ends of the two base side vertical edges 12 are respectively provided with protective rods, and the two protective rods are respectively fixed on the fixing pieces provided on the bottom ends of the two base lateral vertical edges by bolts;

[0034] The first positioning bracket 20 adopts a frame structure, and a first positioning flat side 21 is connected to one end of two first positioning side vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com