Fireproof and heat-insulation metal wall

A wall and metal technology, which is applied in the field of fire-proof and heat-insulating metal walls, can solve the problems of environmental pollution, weak structure, and easy collapse, etc., and achieve the effects of improving safety, firm and reliable structure, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

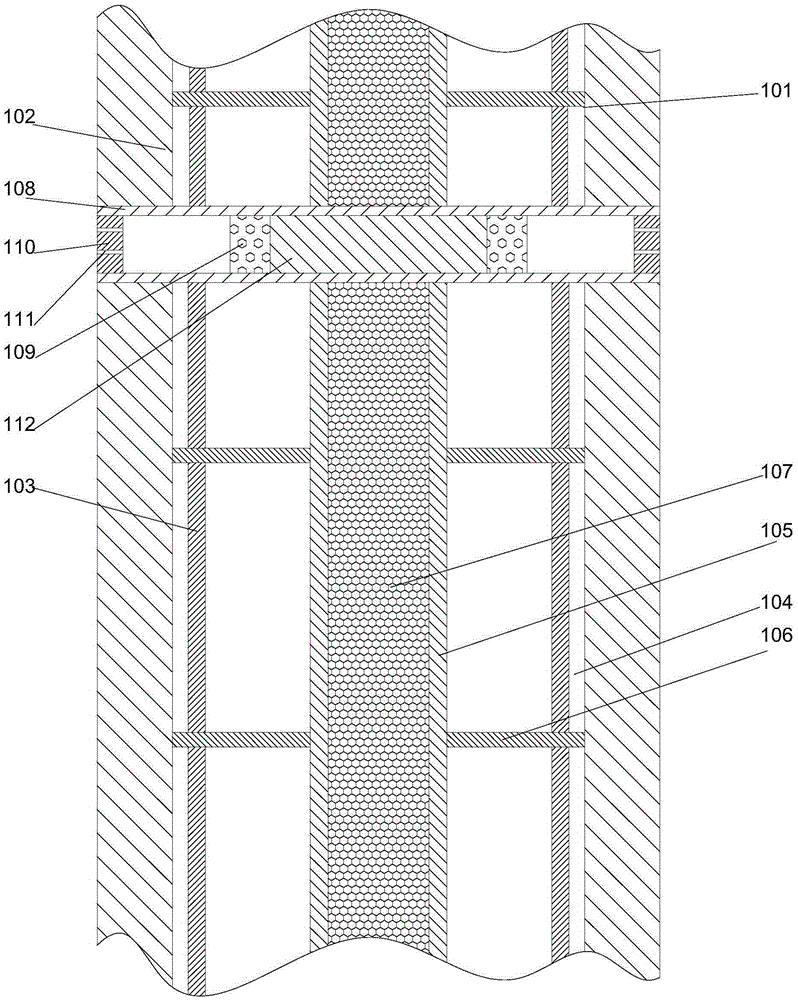

[0019] Such as figure 1 As shown, a fire-proof and heat-insulating metal wall includes an inner wall 101 and an outer wall 102 made of metal materials, and the inner wall 101 and the outer wall 102 are arranged between There is a cavity, and heat insulation layers 103 are respectively arranged on the facing surfaces of the inner wall 101 and the outer wall 102, and the inner wall 101 and the outer wall 102 are opposite to each other. Grooves 104 are respectively arranged on the surface, and the grooves 104 are arranged along the height direction of the inner wall 101, between the inner wall 101 and the outer wall 102 The middle part of the cavity is provided with a reinforcing rib 105 arranged vertically, and reinforcing ribs 106 are respectively arranged on both sides of the reinforcing rib 105, and the reinforcing ribs 106 are arranged at equal intervals along the height direction of the reinforcing rib 105. One end of the reinforcing rib 106 is fixedly connected to the sid...

Embodiment 2

[0022] In this embodiment, on the basis of Embodiment 1, in order to improve the sound insulation effect of the overall structure, in this embodiment, preferably, the inside of the reinforcing rib 105 is a hollow structure, and the middle part of the reinforcing rib 105 is provided with a sound-insulating sponge 107 . In this embodiment, by arranging the sound-proof sponge in the cavity in the middle of the reinforcing rib, the sound-proof effect can be achieved and the possibility of burning the sound-proof sponge can be reduced.

[0023] Further preferably, in order to facilitate installation, in this embodiment, the sound-insulating sponge 107 is bonded to the inner side wall of the reinforcing rib 105 by a fireproof adhesive. Since the sound-insulating sponge has certain flammability, in this embodiment, a fireproof adhesive is used to prevent the sound-insulating sponge from burning.

[0024] In order to make the overall structure have a certain ventilation effect, in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com