Method for sealing and plugging hole bottom of vertical deep hole through hole

A vertical deep hole and hole plugging technology, which is applied in earthwork drilling, sealing/isolation, wellbore/well components, etc., can solve the problem that blasting charges cannot be carried out according to design parameters, and the surrounding space is large, which affects the blasting effect and other issues, to achieve significant economic effects, good effects, and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is further described:

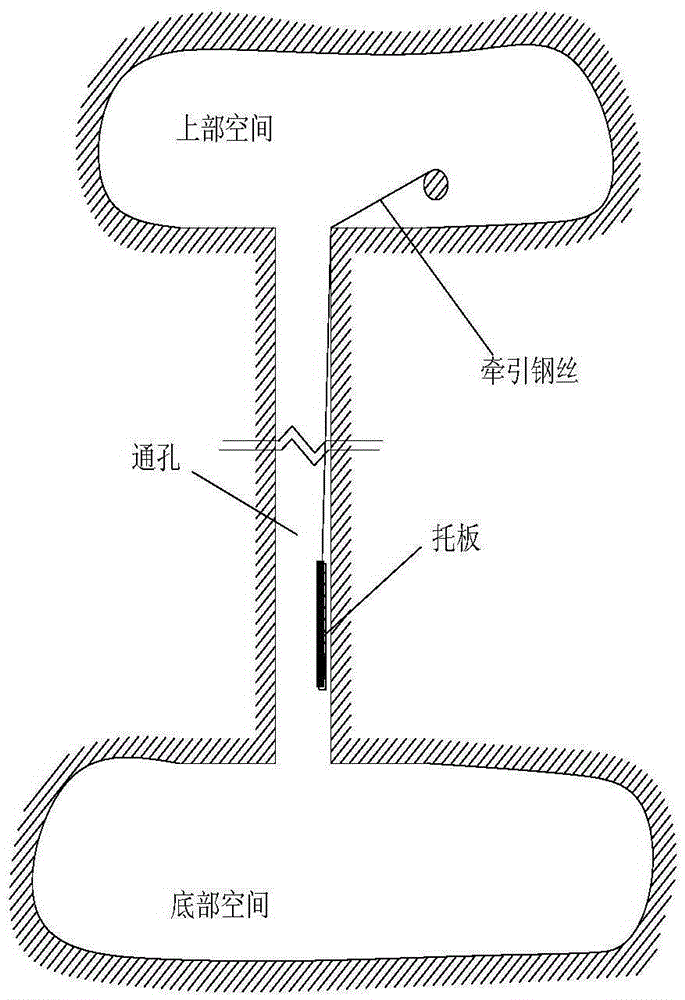

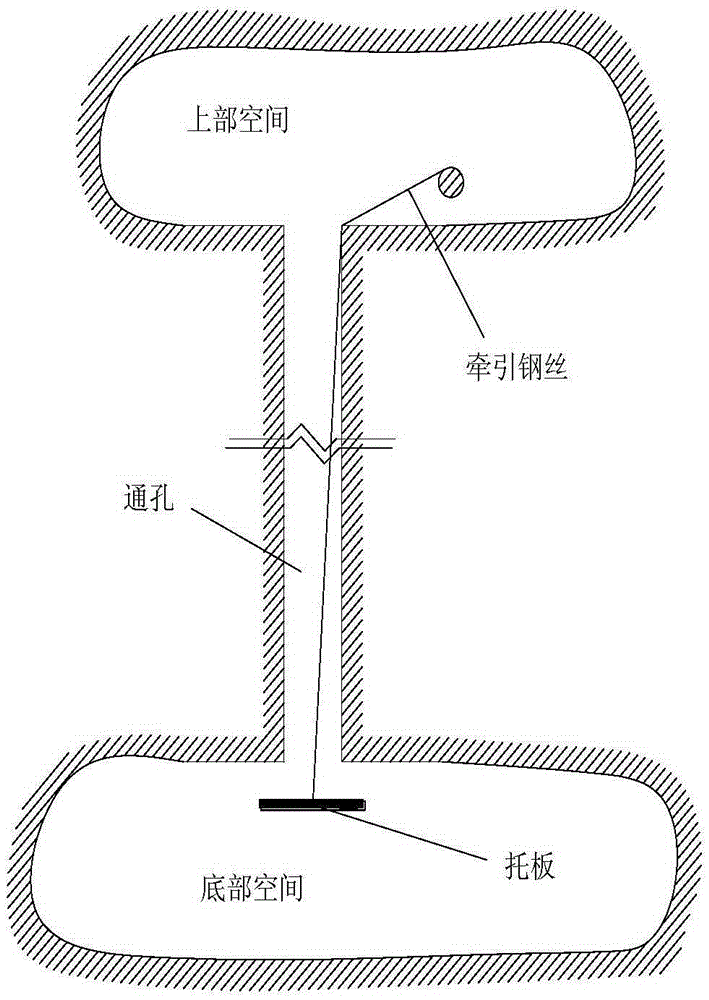

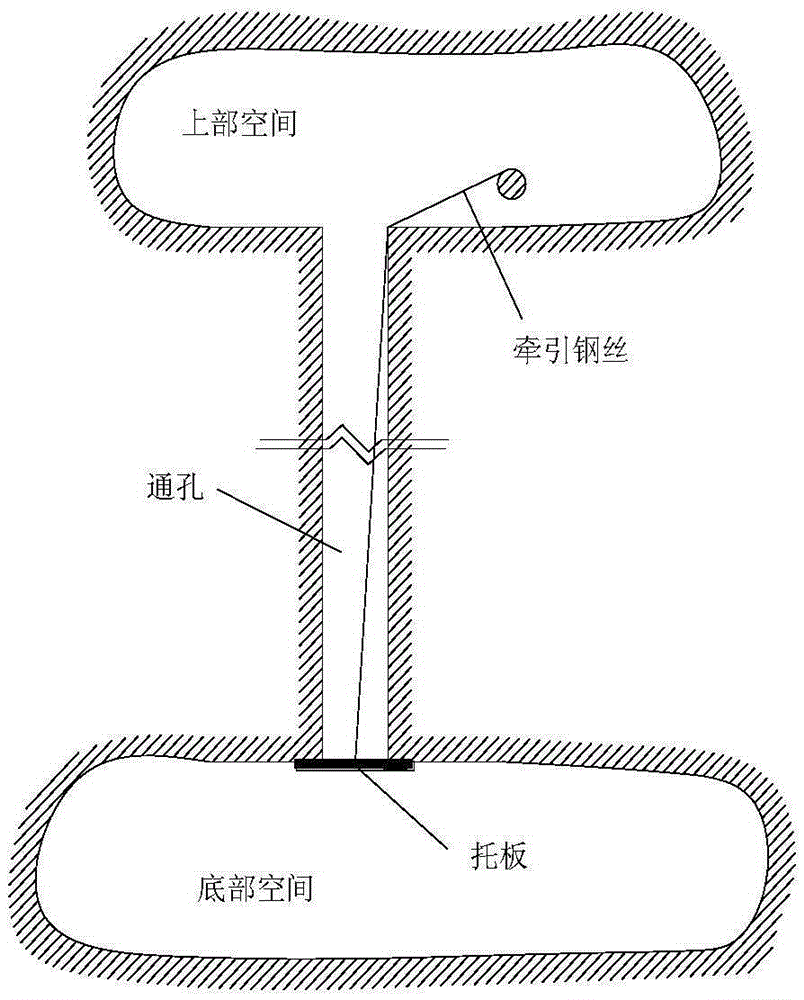

[0019] Such as Figure 1 to Figure 4 As shown, a method for plugging the bottom of a vertical deep hole through hole comprises the following steps:

[0020] Step 1: Bolt the traction wire whose length is greater than the depth of the through hole to the center of the pallet;

[0021] Step 2: Put the supporting plate vertically and pull the steel wire down from the upper space along the through hole;

[0022] Step 3: Continue to lower the steel wire, the pallet slides from its own weight to the bottom of the through hole until it slips out of the through hole and enters the bottom space, the pallet will turn to a horizontal or nearly horizontal state due to its self-weight balance;

[0023] Step 4: Tighten the traction steel wire upward until the supporting plate is clamped to the bottom of the through hole, and fix the traction steel wire in a stable po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com