Wind turbine blade tip lightning protection device

A technology of wind power generator and lightning protection device, which is applied in the direction of wind power generator, wind power generation, engine, etc. It can solve the problems of inconvenient installation and maintenance, poor safety, high cost, etc., and achieve the prevention of blade tip damage, ensure conductive connection, and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

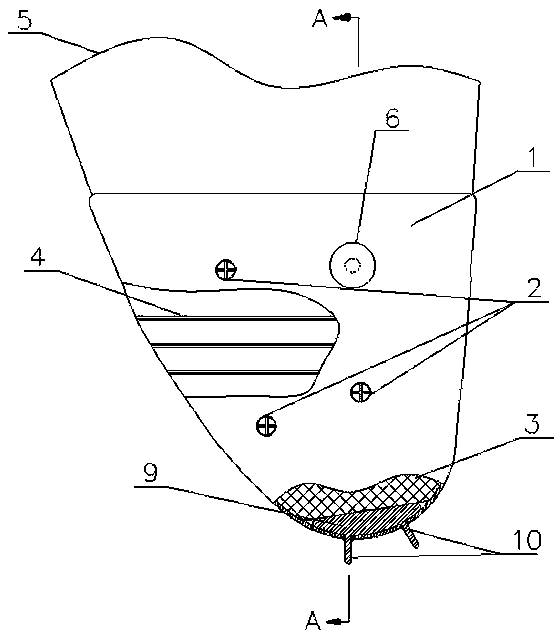

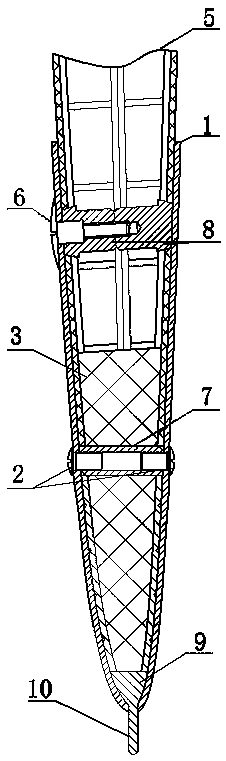

[0020] Embodiment 1: as Figure 1-2 As shown, the wind turbine blade tip lightning protection device includes a metal protective cover 1 installed on the tip 3 of the fan blade 5, and a lightning receptor electrically connected to the metal protective cover 1. A through hole, the lightning receptor is provided with an external contact 6, the external contact 6 is a pan head bolt structure, the external contact 6 is threaded with the internal contact 8 installed in the blade 5 and electrically connected, the lightning The device is conductively connected with the metal protective cover 1 through the external contact 6 that is placed in the first through hole. There are three sets of second through holes correspondingly set on the metal protective cover 1 and the blade tip 3 respectively. The metal protective cover 1 The sleeve 1 is fastened and connected with the blade tip 3 through a fastener placed in the second through hole. The fastener is composed of two bolts 2 and a slee...

Embodiment 2

[0021] Embodiment 2: as Figure 1-2 As shown, the thickness A of the metal protective sheath 1 is 0.7mm, and the material of the metal sheath 1 is aluminum. The distance between the annular grooves 4 is 20 mm, the groove width of the annular grooves 4 is 3 mm, and the groove depth is 1.5 mm. All the other structures are as described in Example 1.

Embodiment 3

[0022] Embodiment 3: as Figure 1-2 As shown, the thickness A of the metal protective sleeve 1 is 0.9 mm, the material of the metal protective sleeve 1 is stainless steel, the distance between the annular grooves 4 is 25 mm, the groove width of the annular groove 4 is 4 mm, and the groove depth is 2mm. All the other structures are as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com