Fan filter unit and clean room

A technology for fan filtration and clean room, which is applied to machines/engines, mechanical equipment, liquid fuel engines, etc., can solve problems such as inability to achieve cleanliness, difficult to maintain or repair, disconnected equipment circuits, and achieve simple structure, lamps and lanterns. The effect of dispersing and reducing lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

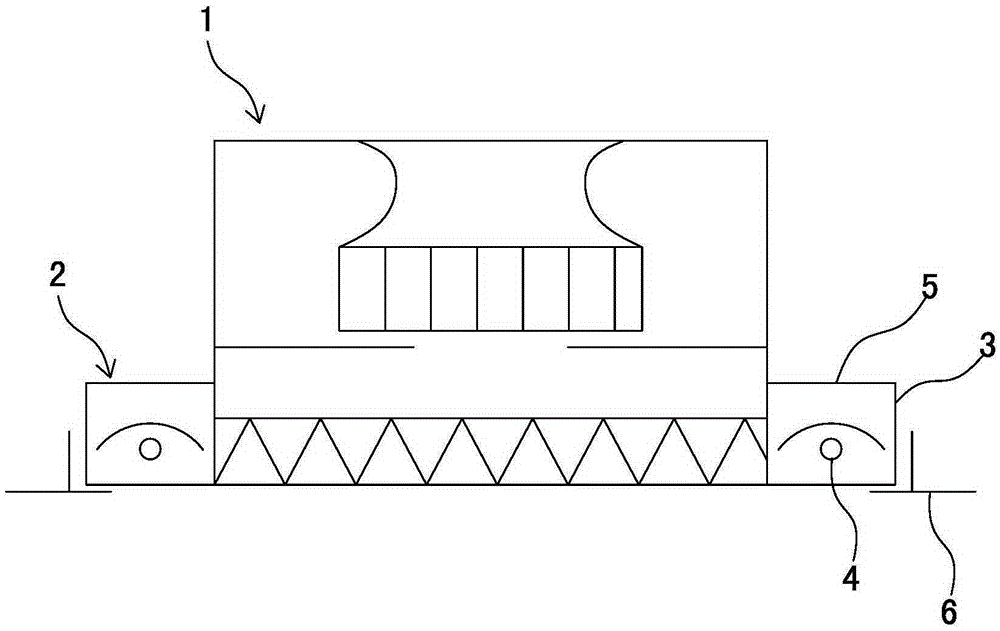

[0033] see figure 1 As shown, a fan filter unit includes a fan filter unit body 1, a lamp 2 is provided on the side of the fan filter unit body, and the power cord of the lamp is integrated with the power cord of the fan filter unit. Both sides of the body of the fan filter unit are symmetrically provided with lamps.

[0034] The main body of the fan filter unit and the lamp form a detachable connection structure.

[0035] The lamp includes a housing 3 and a lamp tube 4 arranged in the housing, and a window for replacing the lamp tube is provided on the top of the housing. A cover plate 5 is provided at the replacement window of the lamp tube.

[0036] The above-mentioned fan filter unit is installed in the ceiling grid 6 to be assembled into a clean room structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com