Connection structure for high-strength concave-convex groove square tubes or round tubes

A technology for connecting structures and square rectangular tubes, which is applied in the direction of connecting components, rods, mechanical equipment, etc., can solve the problems of low moment of inertia and difficult connection of round steel tubes, achieve strong flexibility, reduce operation difficulty, and achieve good results Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

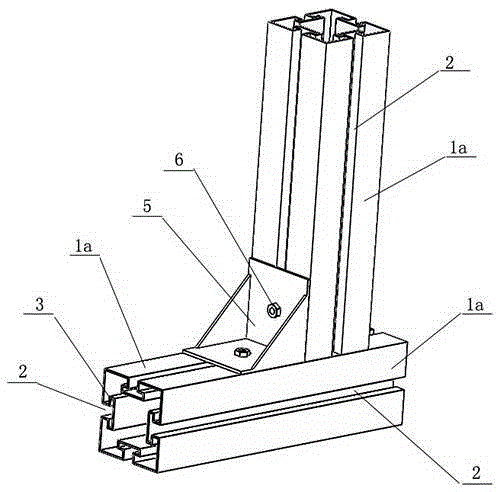

[0036] Embodiment one: if Figure 1-Figure 3 The high-strength concave-convex groove square rectangular tube connection structure shown. Corner connector 5 between two converging rectangular tubes 1a.

[0037] Such as Figure 4 and Figure 5 As shown, the corner connector 5 includes a vertical plate and a horizontal plate, both of which are fixed as one and provided with connecting ribs. Adjustment holes are respectively arranged on the vertical plate and the horizontal plate, and flip clamps are installed in the adjustment holes. The overturning clip includes a rectangular overturning block 7 . A pair of corners of the flipping block 7 of the rectangle is set as arc chamfering,

[0038] One side of the rectangular overturning block 7 is fixedly connected with a rotary screw, and the rotary screw is matched and sleeved in the adjustment hole, and a fixed nut 6 is installed on the rotary screw.

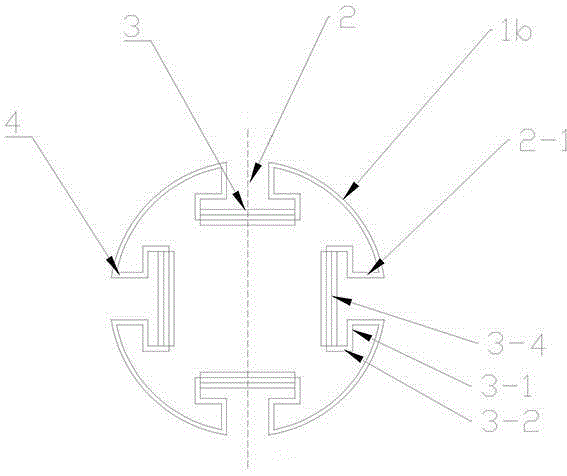

[0039] Such as Figure 7 As shown, the side wall of the square tube 1a is p...

Embodiment 2

[0043] Embodiment two: if Figure 6 As shown, on the basis of Embodiment 1, a tapered perforated hole is set in the center of the turning brick, and the rotating screw is connected with the turning brick through the perforated hole.

Embodiment 3

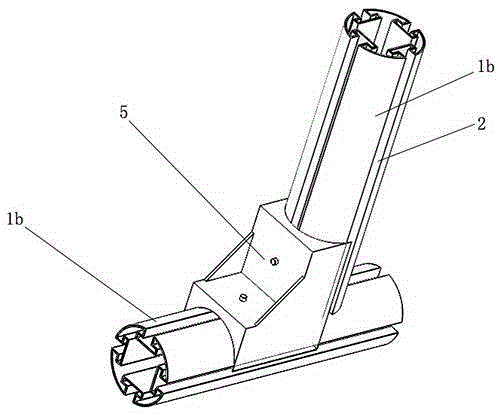

[0044] Embodiment three: see Figure 8 , on the basis of Embodiment 1, modify the corner connection. A support 8 is provided on the side of the connecting rib of the corner connector 5, and a through hole is provided on the support 8, and a hooked pull rod 9 is matched and installed in the through hole, and the hook end of the pull rod is hooked on the square tube 1a or In the embedded groove of the circular rectangular tube 1b, the other end of the pull rod is fixed on the support 8 through a nut.

[0045] In addition, in this embodiment, the bottom surface of the embedded groove is used as the antinode bottom surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com