Horizontally-feeding biomass particle combustion machine

A technology of biomass particles and horizontal feeding, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve the problems of long combustion time, small backfire risk, increase of combustion particles, etc., to improve practicability and convenience Effect of cleaning dust and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

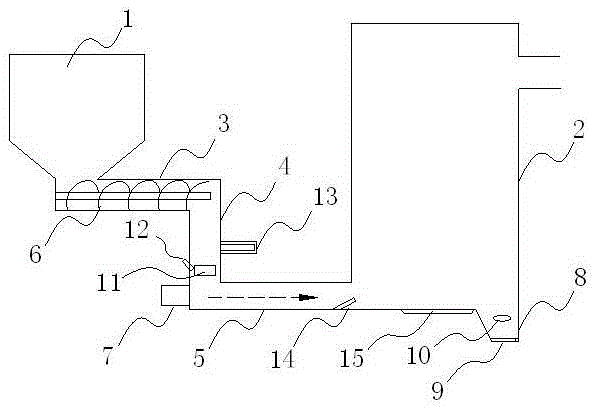

[0018] As shown in the figure, the horizontally fed biomass particle burner of this embodiment includes a hopper 1 and a gasification chamber 2, and the hopper 1 is connected to the gasification chamber 2 through a feed pipe; the key point is that the feed pipe consists of a first horizontal The pipe 3, the vertical anti-backfire pipe 4 and the second horizontal pipe 5 are connected in sequence, the first horizontal pipe 3 is higher than the second horizontal pipe 5; the first horizontal pipe 3 is connected to the bottom of the hopper 1, The first horizontal pipe 3 is provided with a screw feeding device 6 driven by a motor; the second horizontal pipe 5 is connected to the side of the bottom of the gasification chamber 2, and the second horizontal pipe 5 is provided with a feeding fan 7, so that The blowing direction of the feeding fan 7 is towards the gasification chamber 2 from the junction of the second horizontal pipe 5 and the anti-backfire pipe 4 (as shown by the dotted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com