Efficient heat exchanger employing reinforced spiral pipe

The technology of heat exchanger and spiral tube is applied in the field of reinforced spiral tube high-efficiency heat exchanger, which can solve the problems of complex forming process, poor heat exchange effect of heat exchanger, and narrow application range, and achieves the improvement of heat transfer efficiency, The high efficiency heat transfer coefficient is stable and continuous, and the effect of increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

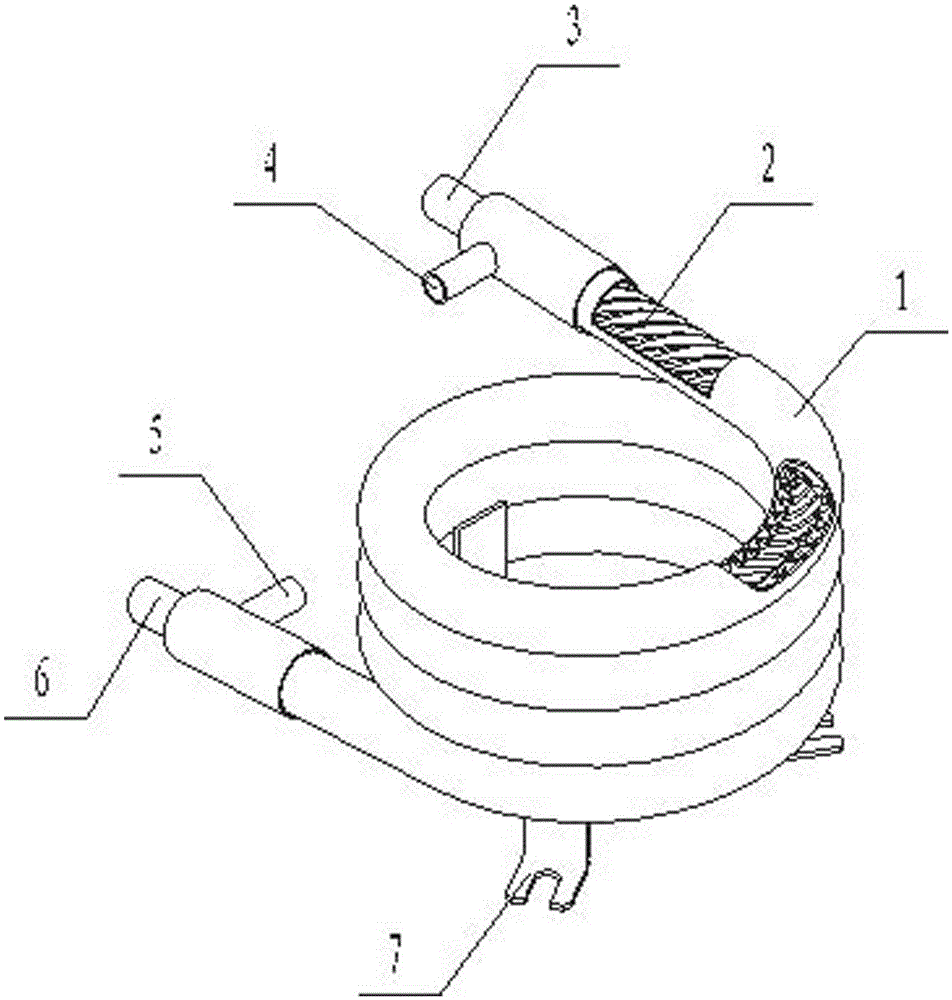

[0037] based on the following Figure 1 to Figure 13 , specify a preferred implementation example of the present invention:

[0038] like figure 1 As shown, it is a reinforced spiral tube high-efficiency heat exchanger, which includes an outer tube 1 and an inner tube 2 .

[0039] Outer tube 1; mouthpiece 1 4 and mouthpiece 2 5 are provided at both ends of the outer pipe 1, mouthpiece 1 4 is the second fluid inlet, mouthpiece 2 5 is the second fluid outlet.

[0040] The inner tube 2 is sheathed inside the outer tube 1, and the inner tube 2 and the outer tube 1 are arranged coaxially.

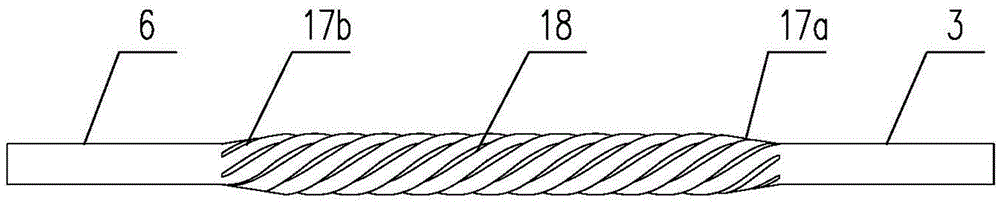

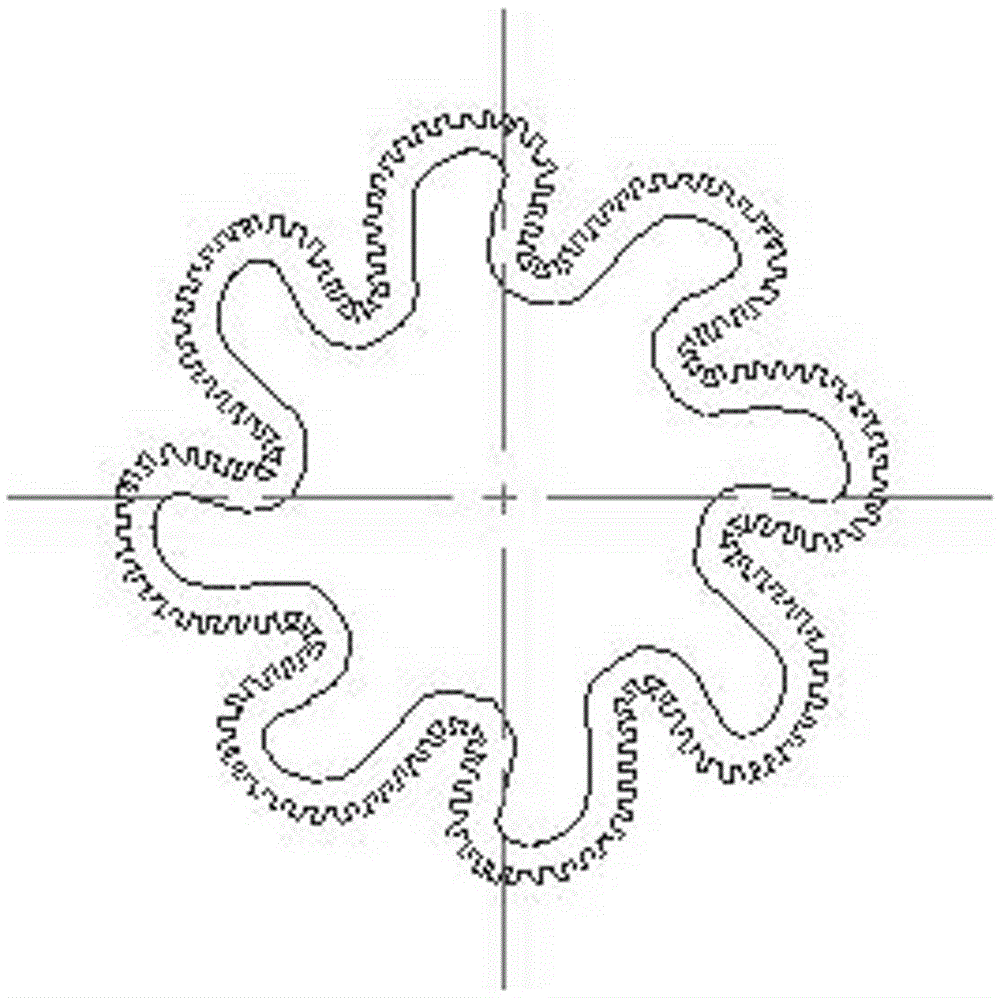

[0041] like figure 2 As shown, the inner tube 2 includes a multi-head helical section body 18, a transition section 17a and a transition section 17b respectively located at both ends of the multi-head helical section body 18, and a contraction section connecting the transition section 17a and the transition section 2 17b respectively. Orifice pipe section one 3 and necking pipe section two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com