Method and apparatus for quantifying dimensional variations and process capability

A technology of process measurement and deviation, applied in the field of determination of size deviation, can solve problems such as uncertainty, error, and difficult to determine parts manufacturing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

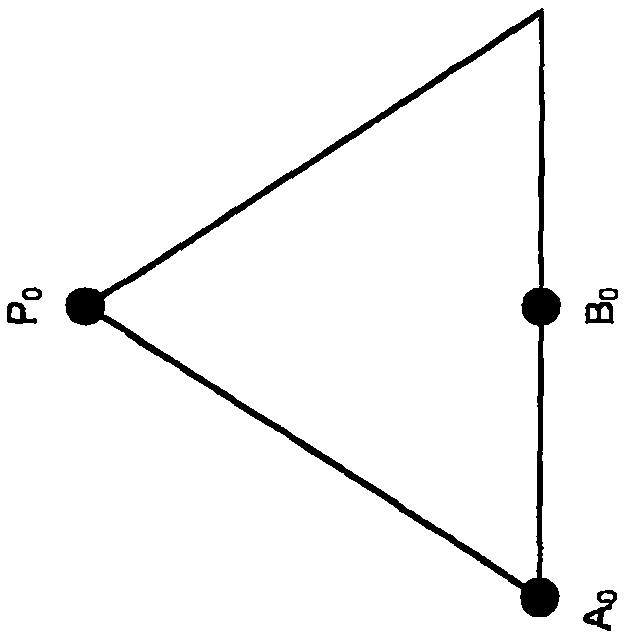

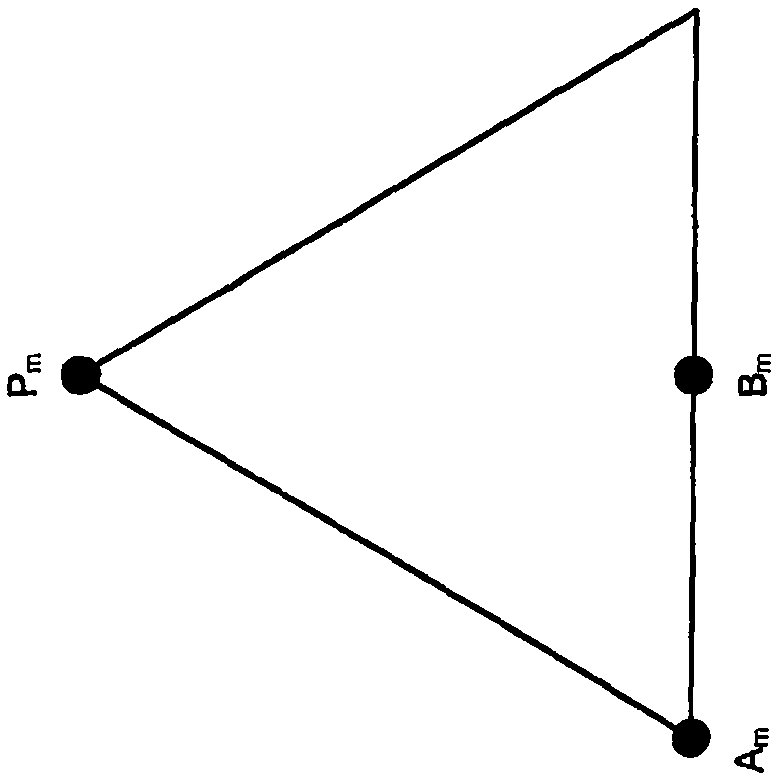

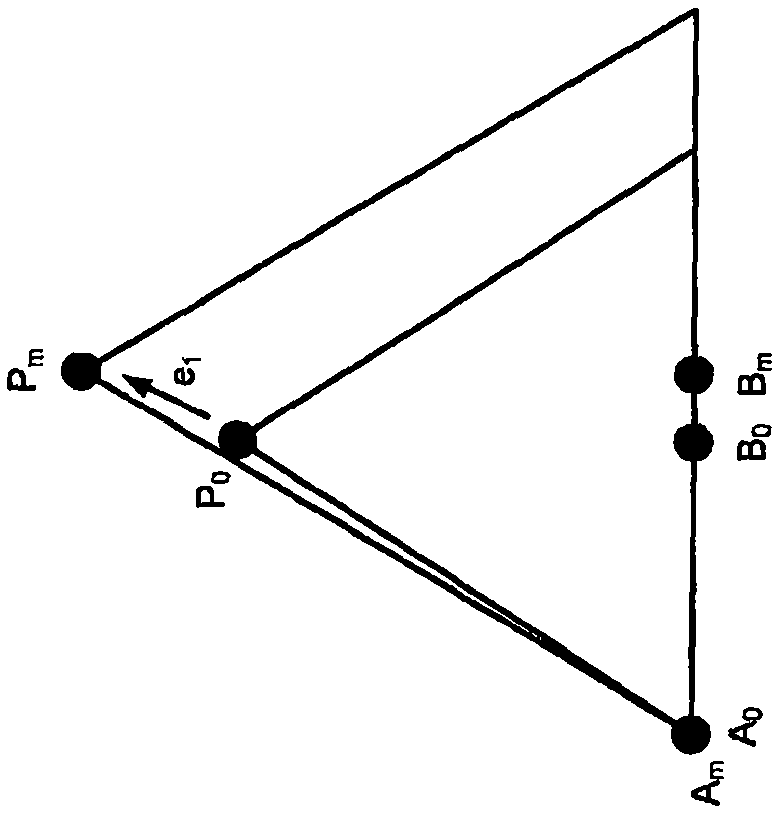

[0110] exist Figure 3A , a design similar to that of Figure 1A for a simple triangular part is shown. design point A 0 , B 0 and P 0 Restricted to design parts. exist Figure 3B shown in the Figure 3A The measurement of the manufactured parts of the design. These measurements may be taken using a coordinate measuring machine or provided using a stylus manually positioned by an operator. These measurement points are A m , B m and P m .

[0111] Note that the manufactured part appears to be rotated relative to the designed part. The rotation can be created based on how the part is attached to the measurement fixture. For example, debris buildup on the fixture itself or on the part can cause the part to sit on the fixture at an angle. Usually, the rotation will be less noticeable than that shown, so for illustration purposes the Figure 3B enlarge.

[0112] According to the present invention, the measurement point of the manufactured part is converted and then rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com