Temperature measuring device for heat pipe monitoring system

A monitoring system and temperature measuring device technology, applied in measuring devices, thermometers using electrical devices, and thermometers with electrical/magnetic components directly sensitive to heat, etc., can solve problems such as low efficiency, low data reliability, and poor accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

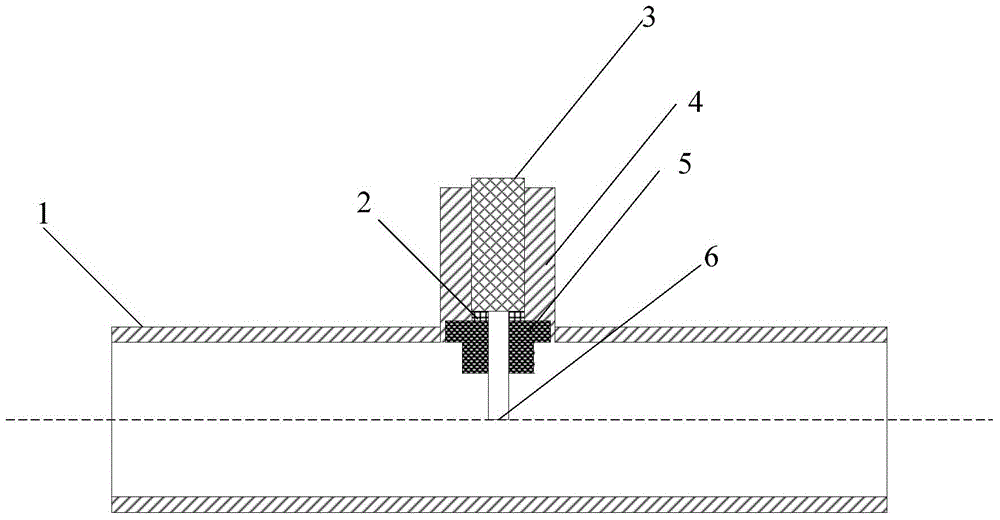

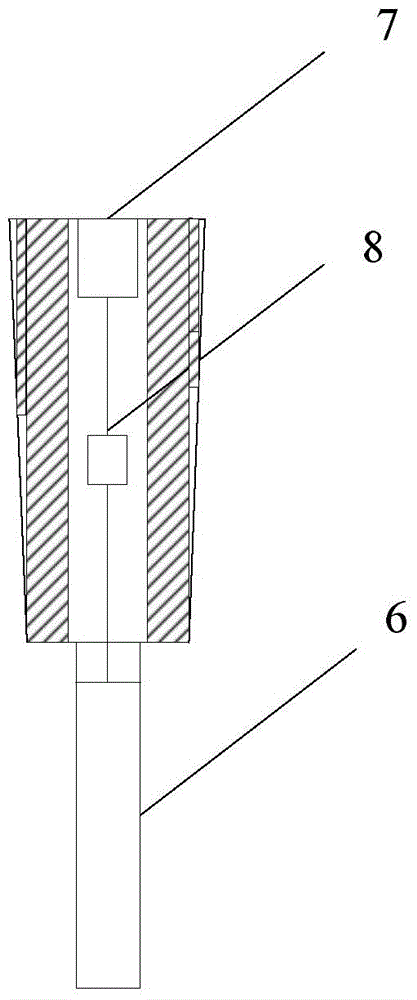

[0020] Such as figure 1 , 2 As shown, a temperature measuring device for a thermal pipeline monitoring system includes:

[0021] Both ends are provided with threaded straight pipe section 1;

[0022] A vertical pipe 4 is vertically arranged in the middle of the straight pipe section 1, and the vertical pipe 4 communicates with the straight pipe section 1 and is set to be hollow, the diameter of the upper end is smaller than the diameter of the lower end, and has a slope of 1 / 1000-1 / 800;

[0023] At the junction of the straight pipe section 1 and the vertical pipe 4, a sealing ring 5 is provided, and the lower end of the sealing ring 5 extends to the inside of the straight pipe section 1;

[0024] A spring washer 2 is arranged on the upper end of the sealing ring 5;

[0025] The probe 6 of the temperature sensor extends into the center line of the straight pipe section 1 through the spring washer 2 and the sealing ring 5;

[0026] The upper end of the probe 6 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com