Multiple Grating Scribes Parallel Interference Controlled Grating Scribing Method

A grating knife and grating scribing technology, applied in the directions of diffraction gratings, optics, optical components, etc., can solve the problems of difficult to achieve precise scribing of large-sized gratings above the meter level, low grating scribing efficiency, etc., and save grating scribing. The effect of reducing the scribing time, improving the grating scribing efficiency, and suppressing the relative rotation angle error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The multiple grating cutter parallel interference control type grating marking method of the present invention comprises the following steps:

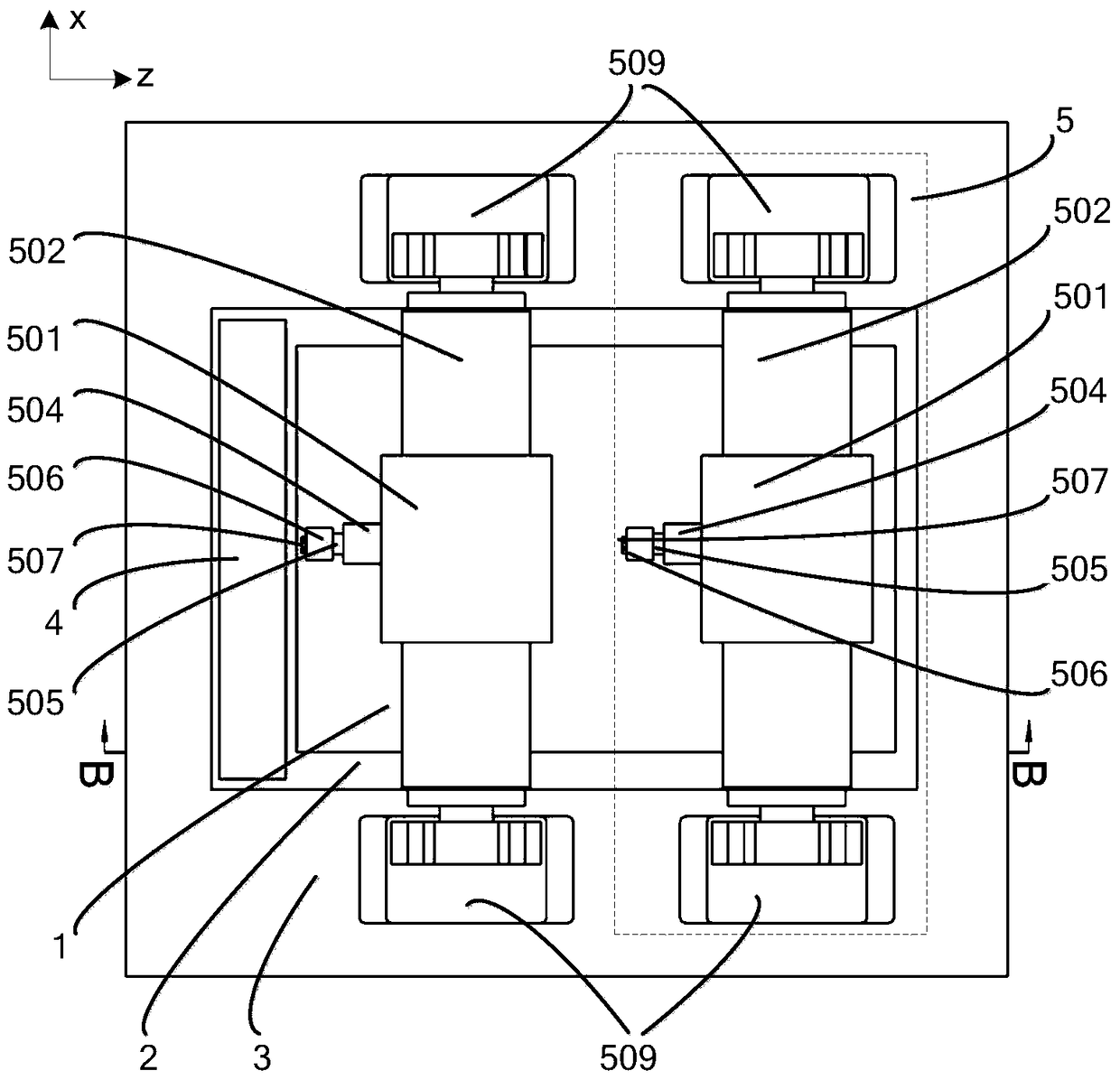

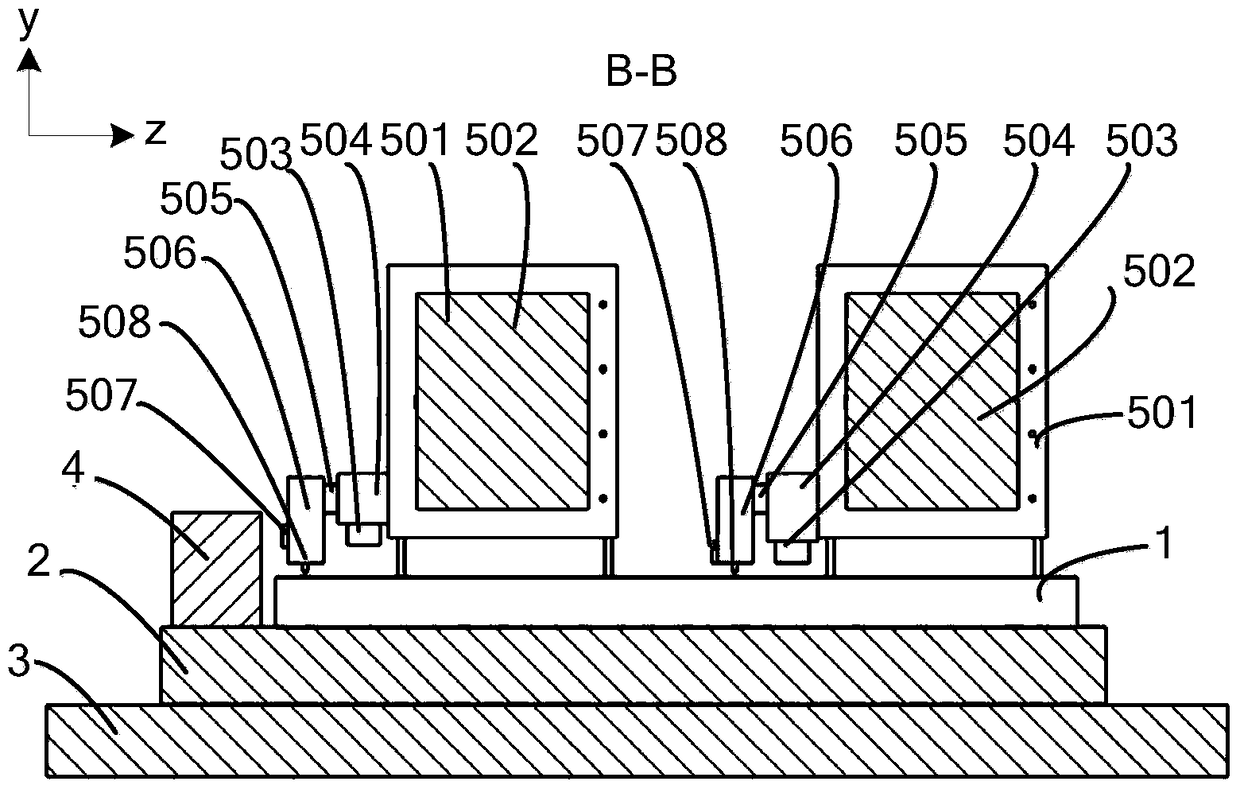

[0051] Step 1: Install two sets of scoring systems 5 in parallel on the main base 3 at a distance of 400 mm, and each set of scoring systems 5 is equipped with a piezoelectric actuator 505, a position measurement interferometer 503 and a reference reflector on the scoring tool holder 506 mirror 507;

[0052] Step 2: install the grating substrate used for the grating blade turning experiment on the grating substrate carrying table 2, and perform the blade turning experiment on the grating cutter 508 in the 2 sets of marking systems 5;

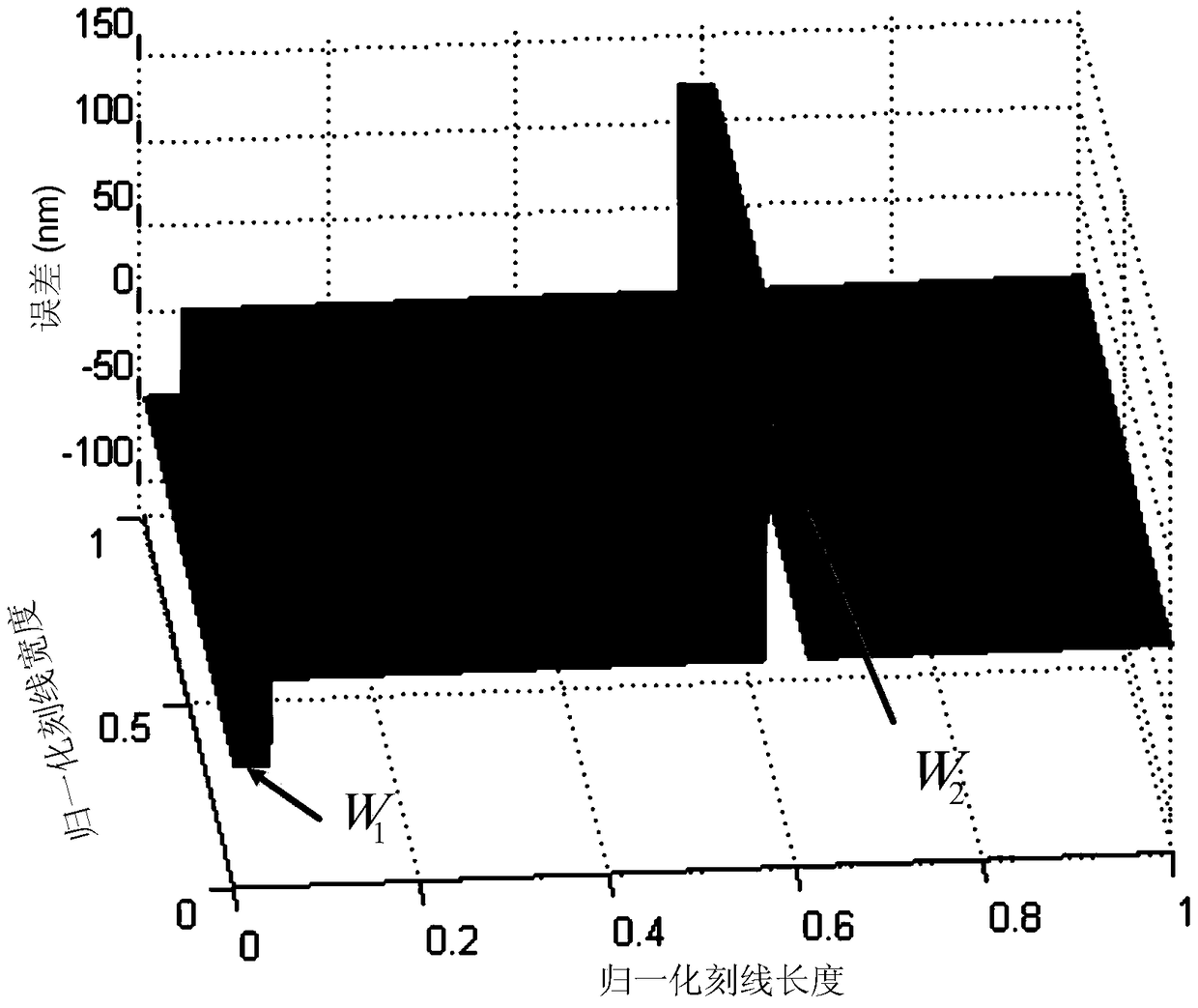

[0053] Step 3: Install the grating substrate used for the grating pre-scribing experiment on the grating substrate carrying workbench 2, conduct the grating pre-scribing experiment, and obtain the position error E of the second sub-grating relative to the first sub-grating 2 ;

[0054] Step 4: A...

Embodiment 2

[0077] The difference between this embodiment and Embodiment 1 is that: the measuring reflector 4 is two pieces, the first measuring reflector 4 is arranged at the end of the grating base bearing workbench 2, and the second measuring reflector 4 is respectively arranged at the second On the scribing tool holder 506 of one set of scribing system 5, the position measurement interferometer 503 in the first set of scribing system 5 measures the distance between the corresponding reference mirror 507 and the measuring mirror 4 on the grating substrate carrying workbench. The position measurement interferometer 503 in the second marking system 5 measures the relative position between its corresponding reference mirror 507 and the measuring mirror 4 set on the first marking system 5 . Except that the length of the first measuring reflector 4 is slightly longer than the length of the grating lines, the other measuring reflectors 4 are relatively small in size, and the size is ≥5mm×5mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com