A safe sodium-sulfur battery

A sodium-sulfur battery, a safe technology, applied in the direction of secondary batteries, battery pack components, battery boxes/coatings, etc., can solve the problems of active material leakage, unsafe structure, etc., to ensure battery safety, discharge speed and depth favorable , Avoid the effect of the battery temperature rising too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

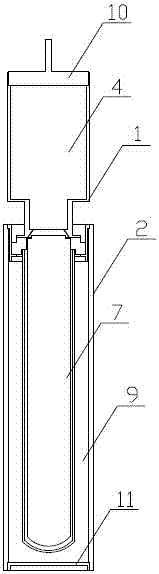

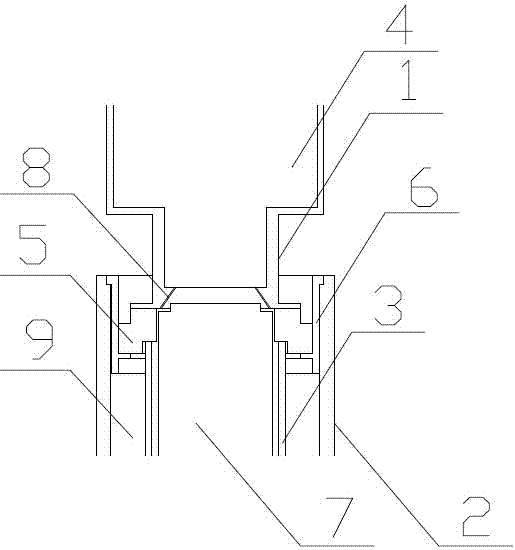

[0023] A safe sodium-sulfur battery, comprising a sodium storage tank 1, a battery casing 2, and a solid electrolyte ceramic tube 3, wherein metal sodium 4 is stored in the sodium storage tank 1, and an insulating ceramic ring 5 is connected to the bottom of the sodium storage tank 1 , the bottom of the insulating ceramic ring 5 is connected to the top of the solid electrolyte ceramic tube 3, and the outer wall of the insulating ceramic ring 5 is connected to the inner wall of the battery case 2 through a metal connector 6; the solid electrolyte ceramic tube 3 The inside of the negative electrode current collector 7 is provided with the top of the negative electrode current collector 7 connected to the sodium storage tank 1; the bottom of the sodium storage tank 1 is provided with an inclined aperture channel 8, and the sodium storage tank 1 The inner metal sodium 4 communicates with the gap between the solid electrolyte ceramic tube 3 and the negative electrode current collect...

Embodiment 2

[0026] On the basis of embodiment 1:

[0027] Preferably, the width of the gap between the solid electrolyte ceramic tube 3 and the negative electrode collector 7 is 0.5 mm.

[0028] Preferably, the top of the sodium storage tank 1 is provided with a battery top cover 10 for sealing the sodium metal 4 .

[0029] Preferably or further, the bottom of the battery casing 2 is provided with a battery bottom cover 11 for sealing the sulfur electrode 9 .

[0030] Preferably, the upper end of the solid electrolyte ceramic tube 3 is open, and the lower end is a sealed round or flat bottom.

Embodiment 3

[0032] On the basis of embodiment 1:

[0033] Preferably, the width of the gap between the solid electrolyte ceramic tube 3 and the negative electrode collector 7 is 3mm.

[0034] Preferably, the top of the sodium storage tank 1 is provided with a battery top cover 10 for sealing the sodium metal 4 .

[0035] Preferably or further, the bottom of the battery casing 2 is provided with a battery bottom cover 11 for sealing the sulfur electrode 9 .

[0036] Preferably, the upper end of the solid electrolyte ceramic tube 3 is open, and the lower end is a sealed round or flat bottom.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com