Food waste crusher

A technology of kitchen waste and pulverizer, which is used in grain processing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

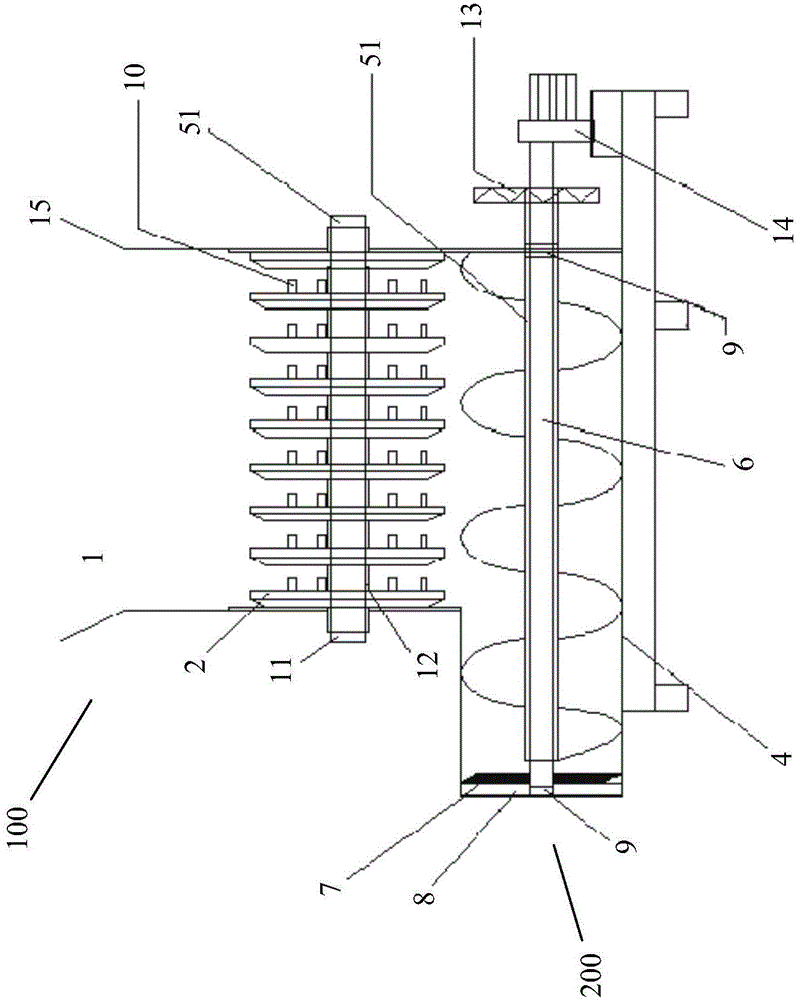

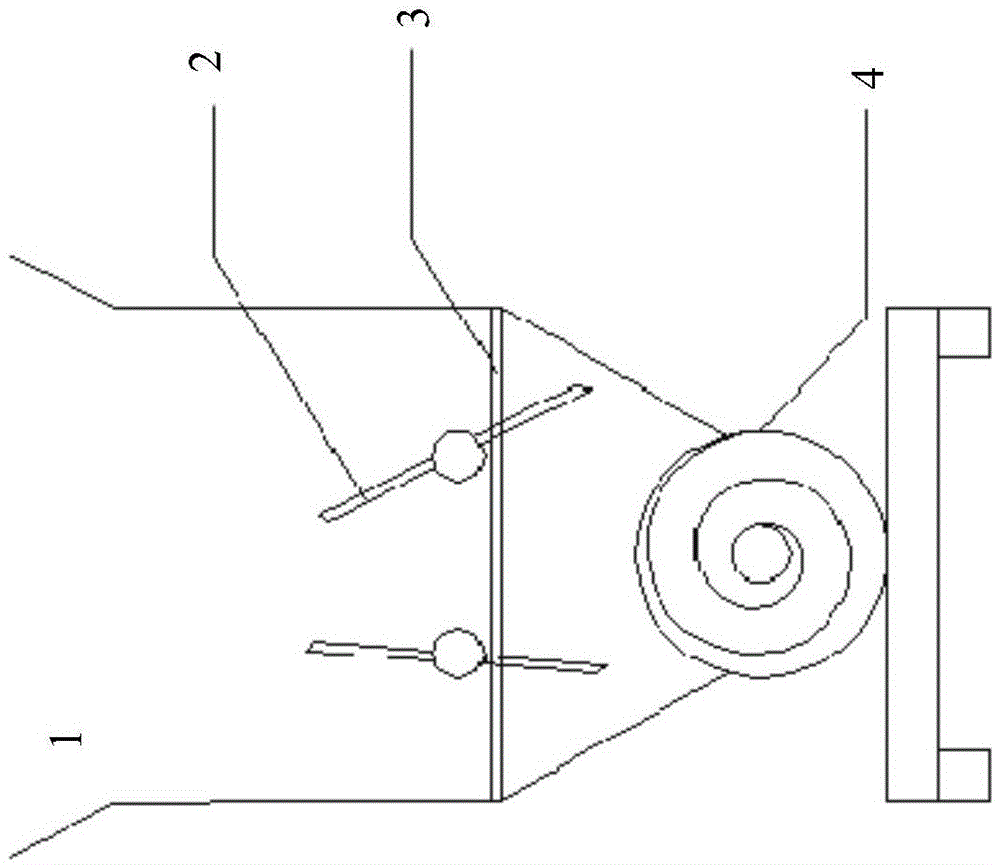

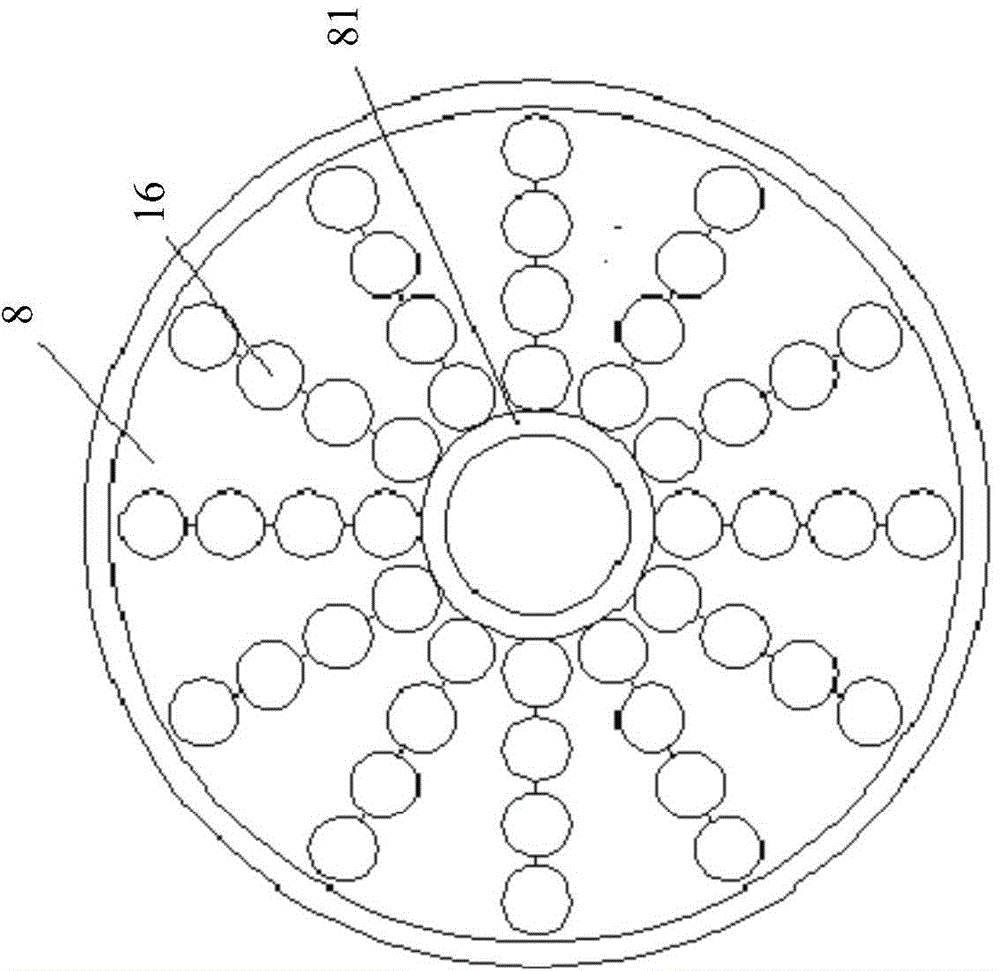

[0040] See figure 1 As shown, the kitchen waste shredder of the present invention comprises a primary crushing bin 100, a secondary crushing bin 200, and a feed port 1, which is arranged in a funnel shape at the top opening of the primary crushing bin 100, below the feed port 1 A transmission shaft 10 is arranged in the primary crushing bin 100, and a bearing sleeve 12 is installed on the outer surface of the transmission shaft 10, and then a bearing 11 is installed on the bearing sleeve 12, which is convenient for installation and maintenance.

[0041] On the vertical axis of the above-mentioned transmission shaft 10, some parallel rotating blades 2 are also arranged, and a fixed crushing blade 3 is horizontally arranged on the transmission shaft 10. When the transmission shaft 10 drives the rotating blade 2 to rotate, the rotating blade 2 and The fixed crushing blade 3 forms a scissors shearing action, thereby primary crushing the materials entering the primary crushing bin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com