Oxidation sand blasting aluminum alloy machine tool operation panel

An operation panel and aluminum alloy technology, applied in metal processing equipment, used abrasive processing devices, abrasives, etc., can solve problems such as aging cracks, reduced service life, corrosion of internal metal support plates, etc., to improve wear resistance Corrosion, improve service life, improve the effect of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

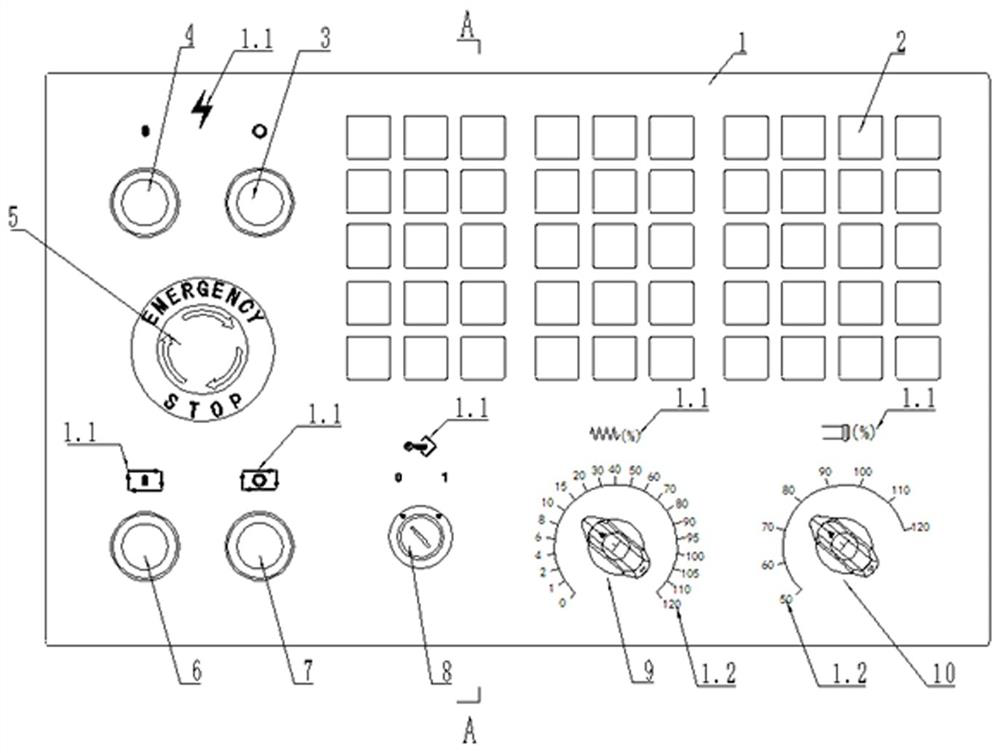

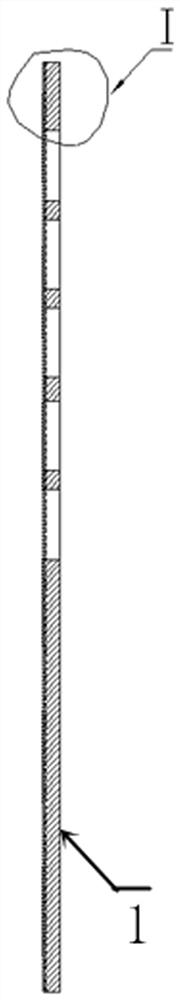

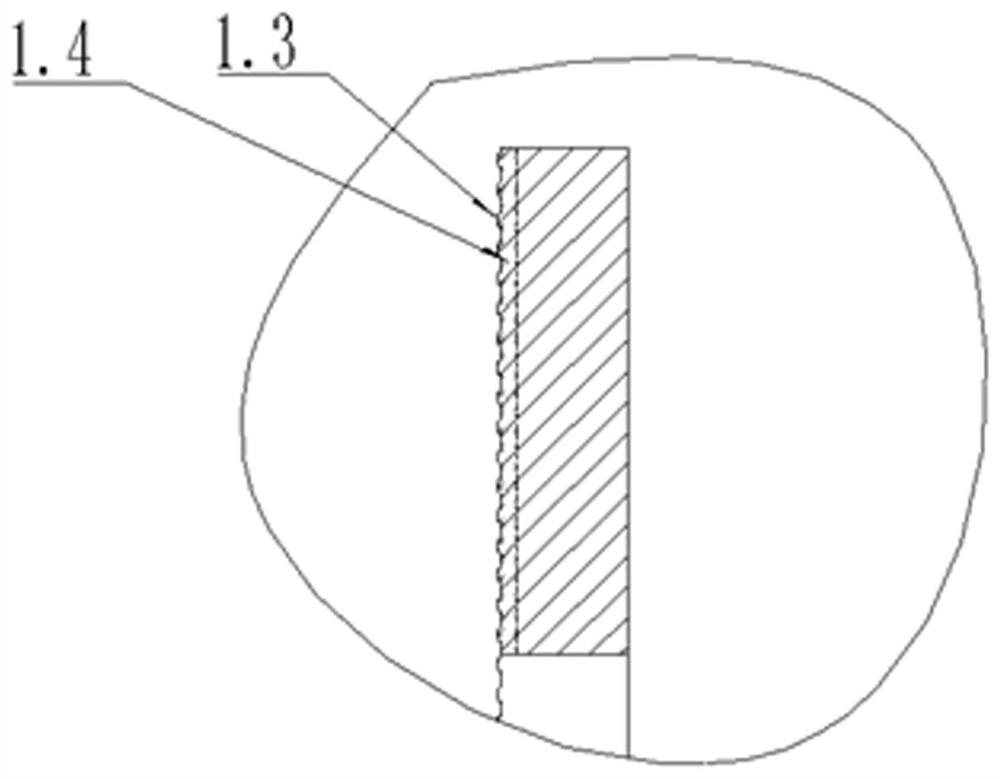

[0015] Such as Figure 1 to Figure 3 As shown, an oxidized sandblasting aluminum alloy machine tool operation panel of the present invention includes a panel body 1, a number of panel function keys 2 and several button switches, and the panel function keys 2 and several button switches are all installed on the panel body 1 , the panel body 1 is made of high-strength and corrosion-resistant 6000 series aluminum-magnesium alloy material, and the surface of the panel body 1 is provided with a sandblasting layer 1.3 and a hard oxide film 1.4 in sequence from the inside to the outside, and the surface of the panel body 1 is processed by a laser machine There are panel characte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com