Angle-adjustable inner circle helical tooth and chute machining device

A processing device and angle adjustment technology, which is applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problems of poor rigidity of the tool, easy to break, high processing difficulty, narrow tooth slot width, etc., and achieves low device cost and processing difficulty. Large, stable positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, patent of the present invention is described in detail:

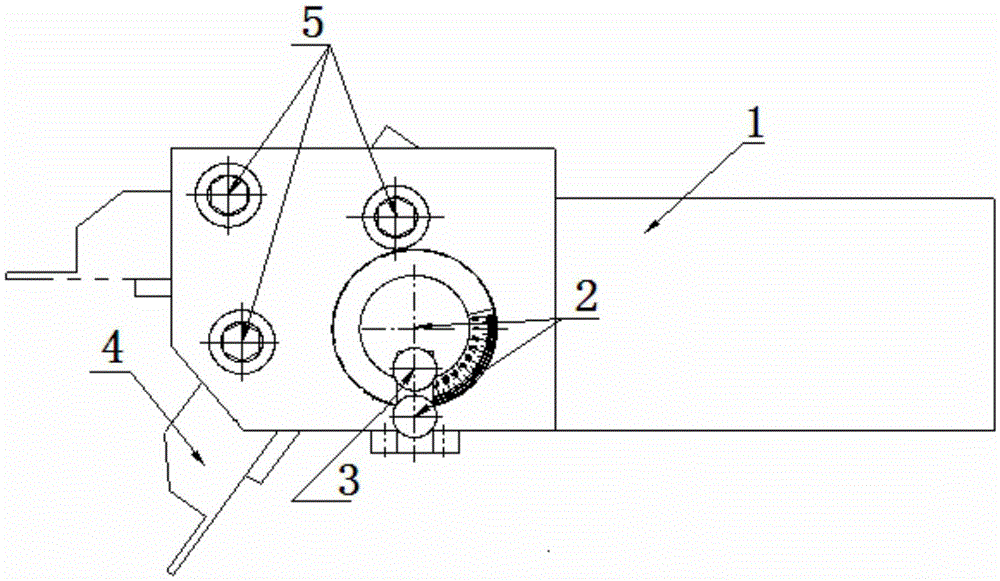

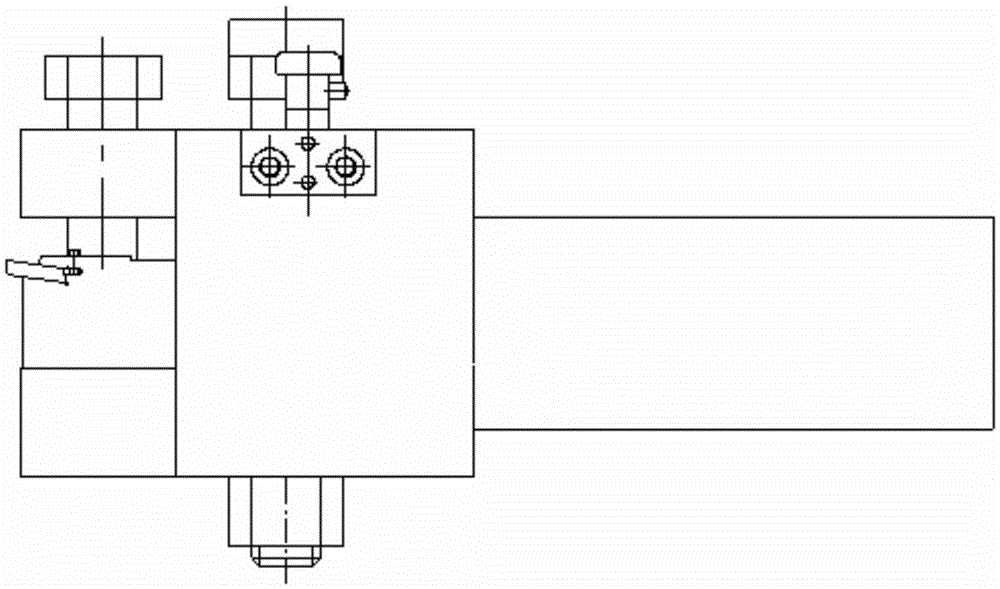

[0021] Such as figure 1 , figure 2 As shown, the present invention is made up of cutter bar 1, angle adjustment unit 2, adjustment locking unit 3, groove cutter 4, three compression screws 5, and described groove cutter 4 is the outsourcing standard groove cutter, is characterized in that: The cutter bar 1 described above has a chute at the end, and the positioning angle θ at which the slot cutter 4 is clamped on the cutter bar 1 is determined by the angles α and β on both sides of the chute on the inner circle of the workpiece, θ=α+(β -α) / 2, α is the angle of the side with a small slope of the groove on the inner circle of the workpiece, and β is the angle of the side with a large slope of the groove on the inner circle of the workpiece; three screws are arranged at the tool bar 1 to clamp the groove cutter 4 The angle adjustment unit 2 and the adjustment lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com