Printing system of self-adhesive label

A printing system and label technology, applied in the field of self-adhesive label printing system, can solve the problems affecting the normal use of labels and low paper utilization, and achieve the effect of easy erasing and normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

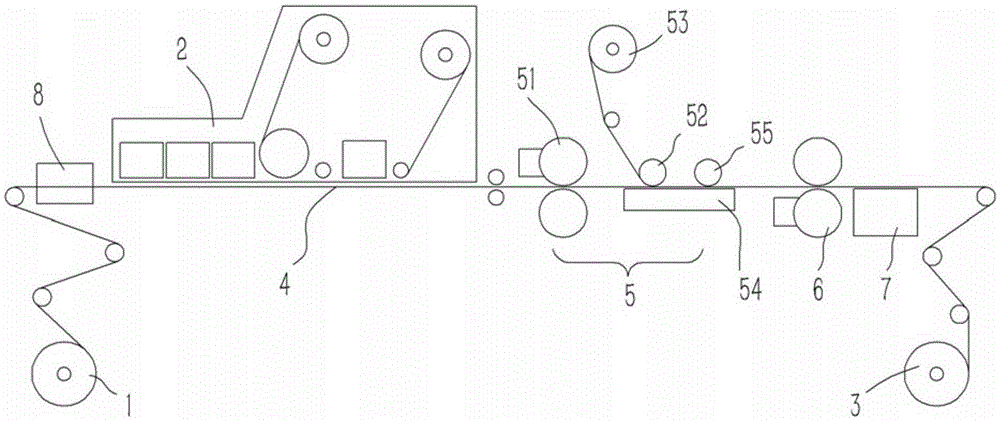

[0013] Example: see figure 1 As shown, a self-adhesive label printing system includes a paper unloading unit 1, a printing unit 2, and a paper delivery unit 3, and the first and last ends of the printing paper 4 are wound on the paper unloading unit 1 and the paper delivery unit 3 respectively. Printing unit 2 is arranged on the printing paper 4 between the paper delivery unit 1 and the paper delivery unit 3, and a film sticking unit 5 is arranged on the printing paper 4 between the printing unit 2 and the paper delivery unit 3. 4. The front glue roller 51 on the front side, the back side of the front glue roller 51 is provided with a lamination roller 52, the top of the lamination roller 52 is provided with a film release roller 53, the rear side of the lamination roller 52 is provided with a pressing roller 55, and the lamination roller 52 and the back side of the printing paper 4 under the pressure roller 55 is provided with a film sticking platform 54 .

[0014] On the pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap