Control device for vehicle

A technology for control devices and vehicles, which is applied in the direction of control devices, transmission devices, power devices, etc., and can solve problems such as driver discomfort and driver discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

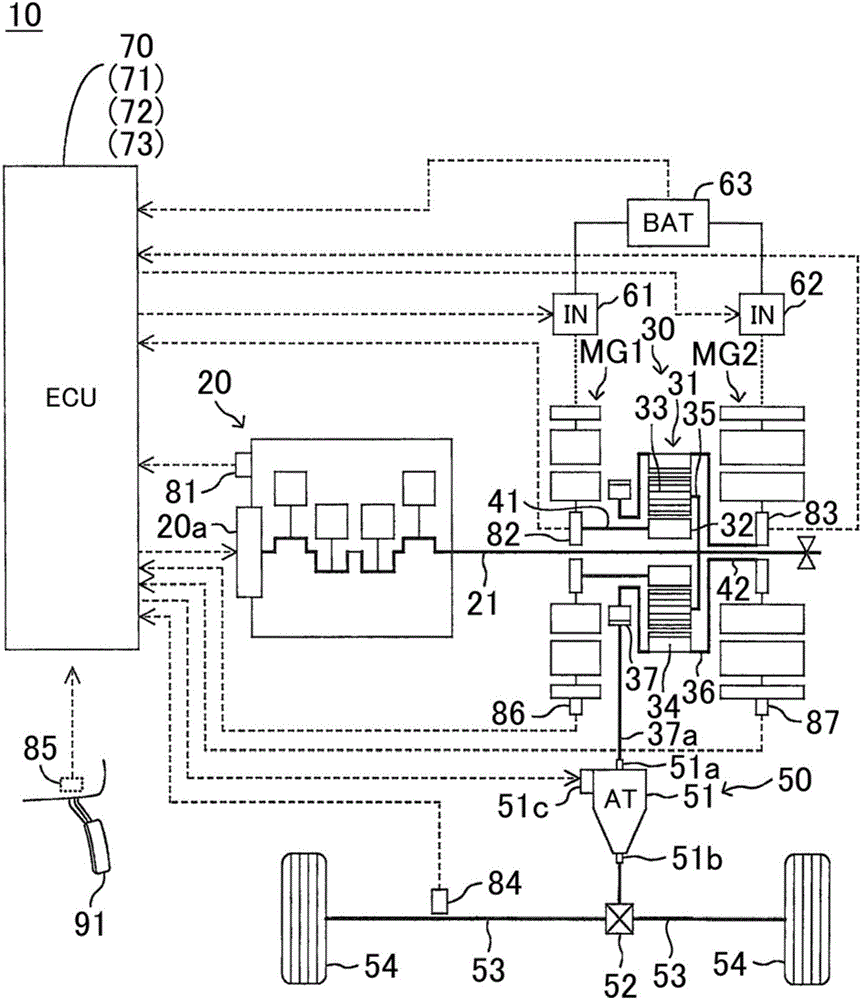

[0044] A control device (hereinafter, referred to as a first device) according to a first embodiment of the present invention is applied to a figure 1 The schematic configuration of the vehicle 10 is shown.

[0045] Vehicle 10 is a hybrid vehicle and includes a first electric motor (generator motor) MG1 , a second electric motor (generator motor) MG2 , and an engine 20 . The vehicle 10 further includes a power distribution mechanism 30 , a power transmission mechanism 50 , a first inverter 61 , a second inverter 62 , a battery 63 , and an electronic control unit (ECU) 70 .

[0046] The first motor MG1 and the second motor MG2 respectively include a stator including three-phase windings (coils) generating a rotating magnetic field, and a rotor including permanent magnets using the rotating magnetic field to generate torque through magnetic force.

[0047] Each of the first electric motor MG1 and the second electric motor MG2 is operable as a motor as well as a generator. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com