Automatic sorting, labeling and unloading device

An automatic sorting and automatic unloading technology, applied in the direction of sorting, transportation and packaging, conveyors, etc., can solve the problems of low efficiency, uneconomical, mixed products, etc., and achieve the effect of improving production efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

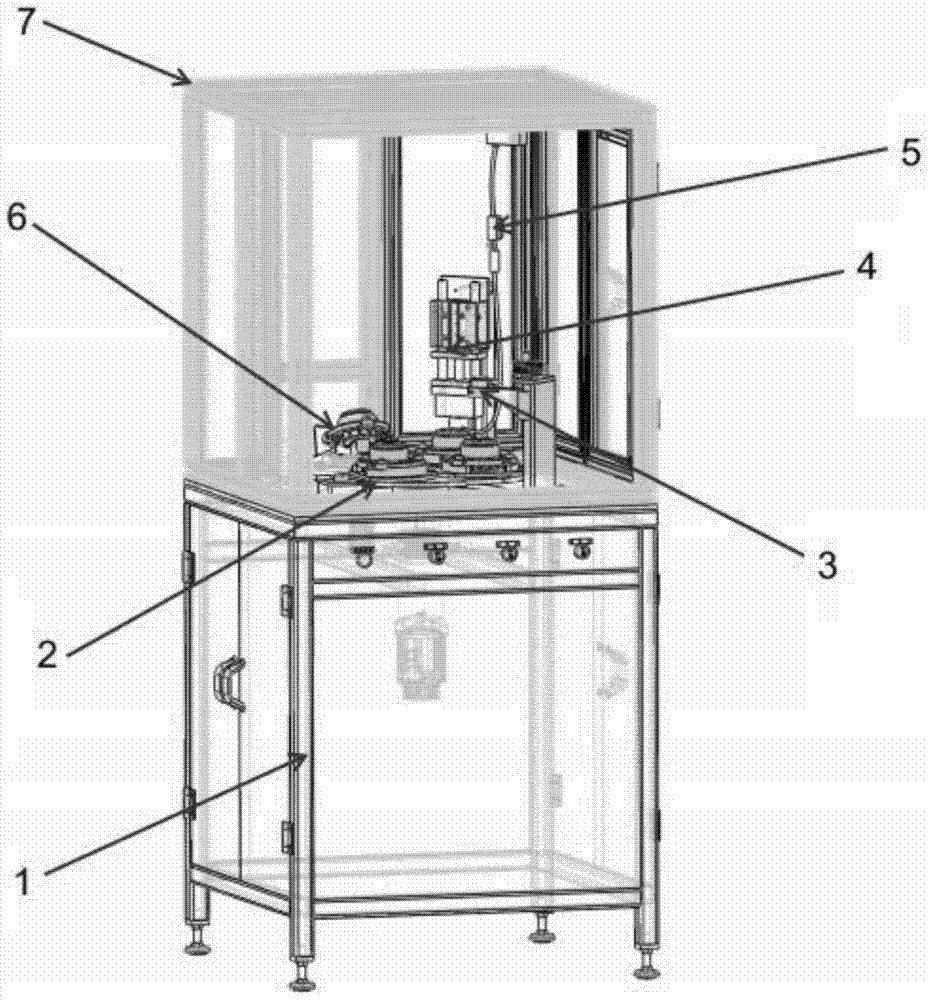

[0033] see Figure 1 to Figure 6 , the present invention discloses an automatic sorting and labeling and blanking device, the automatic sorting and labeling and blanking device includes: a bracket part 1, a rotating device 2, an optical recognition device 3, a color marking device 4, and an automatic ink supply device 5. Automatic feeding device 6. Safety cover and operation panel.

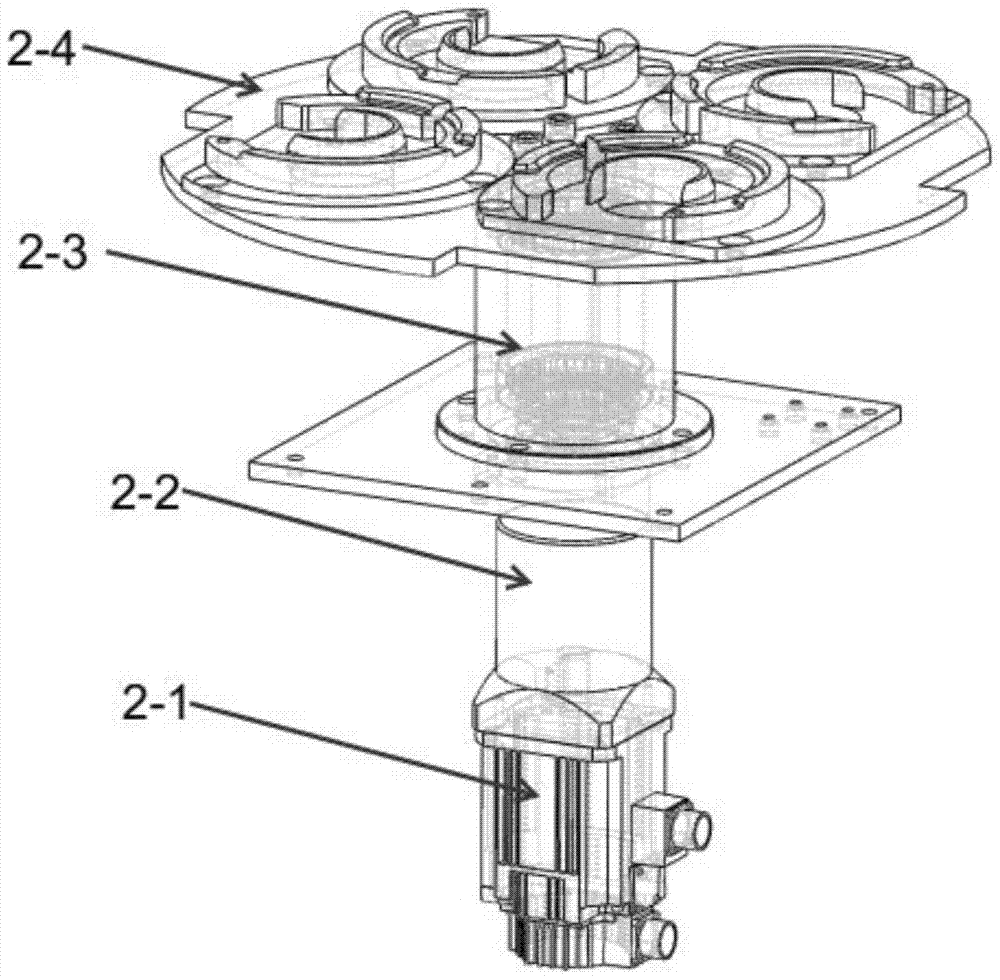

[0034] The rotating device 2 is installed on the bracket part 1, and includes a rotating servo motor assembly 2-1, a galaxy reducer 2-2, a rotating output device 2-3, and a 4-station workbench 2-4; the rotating servo motor assembly 2 -1 Drive the rotary output device 2-3 through the galaxy reducer 2-2 to realize the precise rotation of the 4-station worktable 2-4; place the workpiece on the positioning tool at the first station.

[0035] The rotating servo motor assembly 2-1 is controlled by a controller to realize during the rotating process: loading at the first station, identification at the s...

Embodiment 2

[0042] see figure 1 , the present invention discloses an automatic sorting and labeling and automatic unloading device including a bracket part 1, a rotating device 2, an optical identification device 3, a color marking device 4, an automatic ink supply device 5 and an automatic unloading device 6, Safety cover part 7.

[0043] See figure 2 , the rotating device is driven by the system controller to drive the servo motor 2-1 through the galaxy reducer 2-2 to drive the output device 2-3 to rotate the rotary table 2-4, and place the workpiece on the positioning tool at the first station.

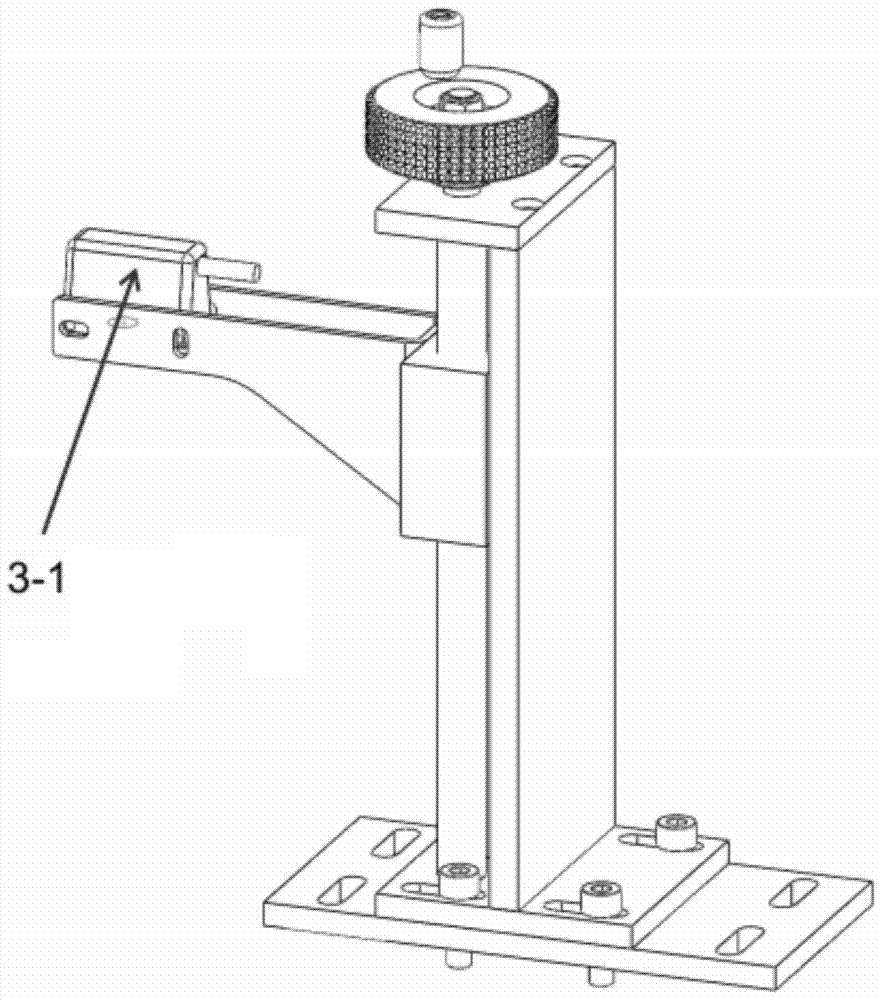

[0044] See image 3 , the optical probe 3-1 of the optical identification device 3 performs identification when the start switch is turned to the second position.

[0045] See Figure 4 , when it is recognized as yes, the system rotates to the third station, and the stamp 4-1 of the color marking device 4 automatically marks the workpiece; then it turns to the fourth station for automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com