Optical protective film processing and coiling mechanism

A technology of winding mechanism and protective film, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problem of more and more serious marks transmission, avoid adverse effects on appearance and performance, and improve appearance and reliability, the effect of thick thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

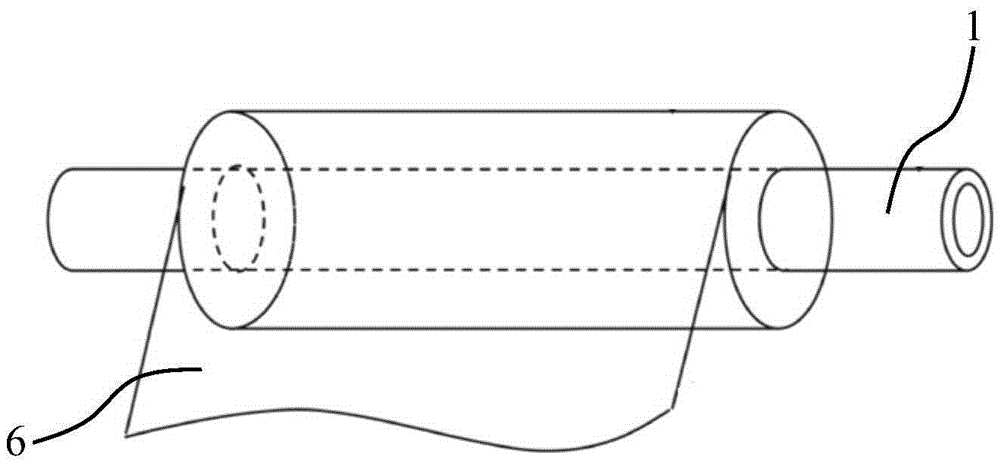

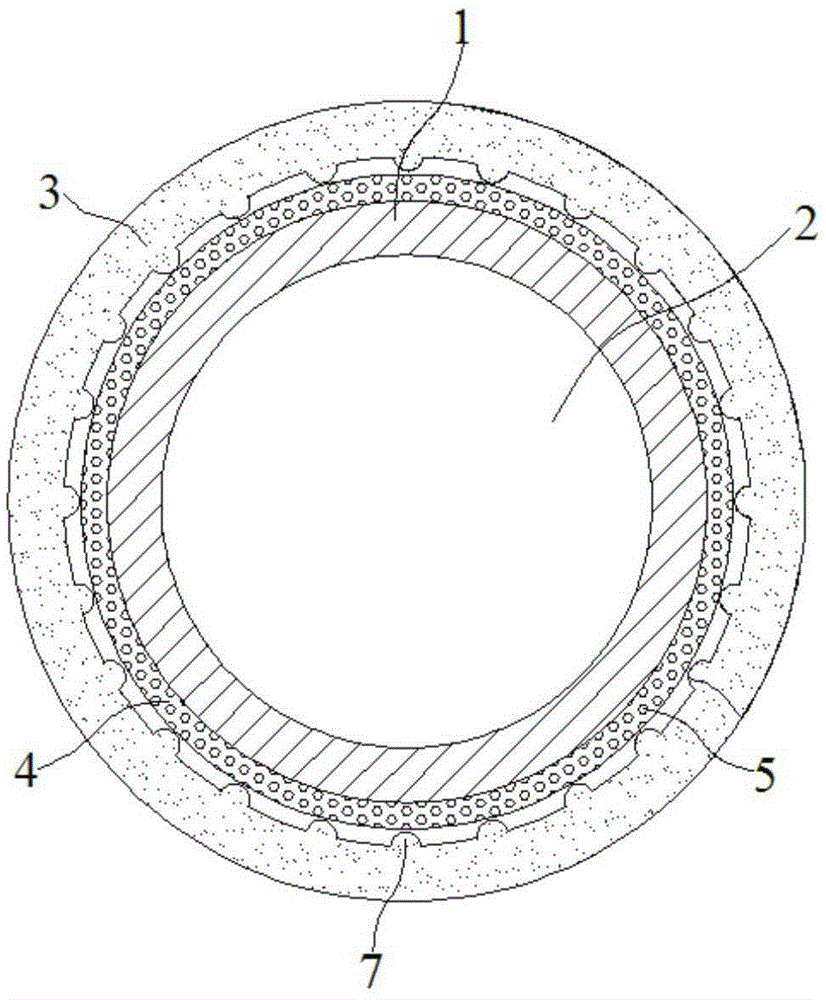

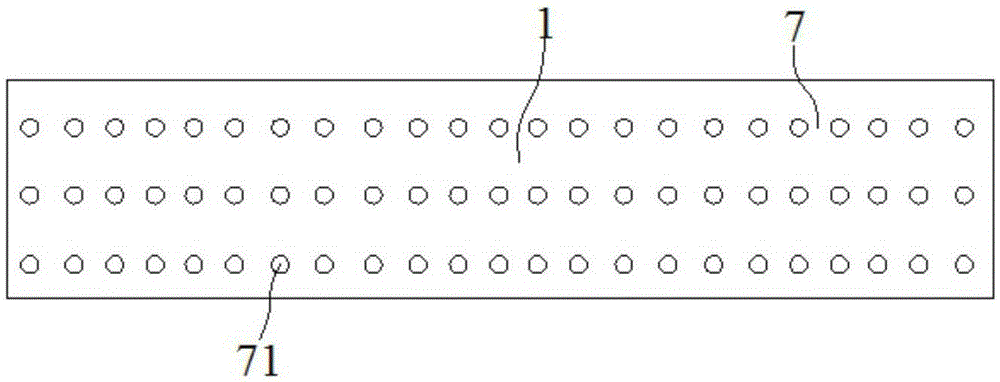

[0017] Embodiment 1: A winding mechanism for optical protective film process, comprising a winding core 1 with a through hole 2 in the center, the outer surface of the winding core 1 is covered with an elastic rubber layer 3, and the elastic rubber layer 3 is in contact with the winding A foam layer 4 is arranged between the cores 1, and the foam layer 4 has several micropores 5 inside;

[0018] The inner surface of the elastic rubber layer 3 in contact with the foam layer 4 is equidistantly distributed along the circumferential direction with a plurality of protruding point bands 6, and the protruding point bands 6 are composed of several protruding points 61 arranged in a straight line. The dot strips 6 are parallel to the axis of the winding core 1 , and the plurality of dot strips 6 are arranged parallel to each other.

[0019] The volume of the above-mentioned several micropores 5 accounts for 60-65% of the volume of the foam layer 4 .

[0020] The thickness of the elast...

Embodiment 2

[0021] Embodiment 2: A winding mechanism for optical protective film process, comprising a winding core 1 with a through hole 2 in the center, the outer surface of the winding core 1 is covered with an elastic rubber layer 3, and the elastic rubber layer 3 is in contact with the winding A foam layer 4 is arranged between the cores 1, and the foam layer 4 has several micropores 5 inside;

[0022] The inner surface of the elastic rubber layer 3 in contact with the foam layer 4 is equidistantly distributed along the circumferential direction with a plurality of protruding point bands 6, and the protruding point bands 6 are composed of several protruding points 61 arranged in a straight line. The dot strips 6 are parallel to the axis of the winding core 1 , and the plurality of dot strips 6 are arranged parallel to each other.

[0023] The volume of the above-mentioned several micropores 5 accounts for 75-78% of the volume of the foam layer 4 .

[0024] The thickness of the elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com