Process for preventing glass from rainbow emergence, and material feeding apparatus thereof

A technology of production process and feeding device, which is applied in the field of float glass and can solve problems such as the inability to use automotive glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A production process for preventing glass from appearing rainbows, characterized in that 150-400g of pig iron with a purity of 99.9% is divided into 7-9 equal parts of iron sheets, preferably iron sheets are 150, 200, 250, 300, 350 or 400 Pig iron with a purity of 99.9% is divided into 7-9 equal parts and added to the feeding device; the feeding device evenly pushes 7-9 pieces of 150-400g iron chips with a purity of 99.9% to the tin liquid every 1 hour Inside.

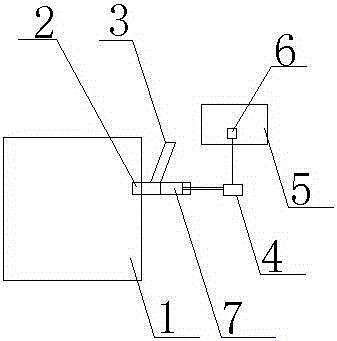

[0010] Feeding device (such as figure 1 Shown) includes a straight cylinder 2, a blanking inclined tube 3, a cylinder 4, a single-chip microcomputer 5 and a display screen 6, a hole is opened on one side of the tin bath body, and a hole is opened on the straight cylinder 2, and the straight cylinder 2 is installed on one side of the tin bath body hole, and one end of the straight cylinder 2 is located in the tin bath body, one end of the inclined tube 3 is connected to the hole on the straight cylinder 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com