Henry steudnera tuber controlled-release fertilizer, and preparation method thereof

A controlled-release fertilizer and taro technology, which is applied in the field of taro controlled-release fertilizer and its preparation, can solve the problems of human body damage, low utilization rate, and large pesticide residues, and achieve the goals of reducing dosage, improving utilization efficiency, and shortening the growth cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

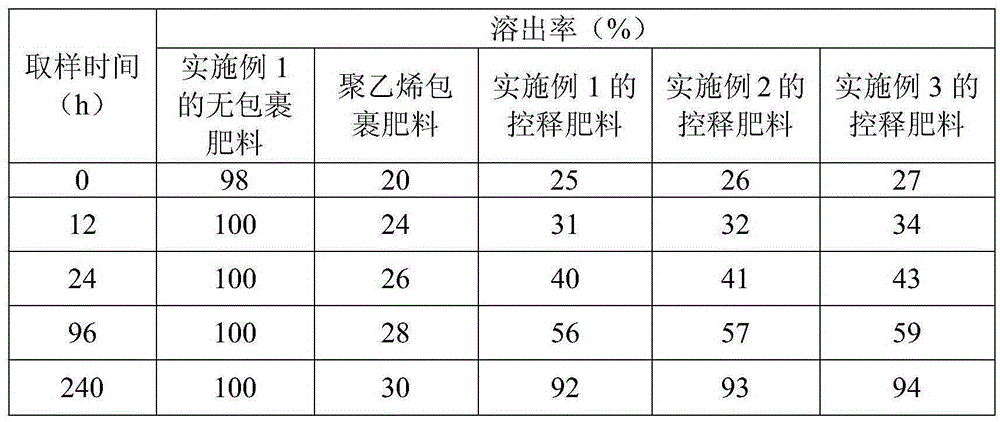

Embodiment 1

[0057] A taro controlled-release fertilizer, which comprises the following raw materials in parts by weight: 30 parts of wrapping materials and 600 parts of fertilizer granules;

[0058] The wrapping material is in parts by weight and includes the following raw materials: 27 parts of fatty acid amide, 0.8 part of ammonium phosphate, 0.8 part of potassium nitrate, 0.8 part of zinc nitrate, 0.1 part of calcium borate, 0.1 part of ferric chloride, and 0.1 part of zinc chloride , 0.1 part of manganese chloride, 0.1 part of copper chloride, 0.1 part of polyacrylamide;

[0059] The fertilizer granules are in parts by weight and include the following raw materials:

[0060] 60 parts of aconitum, 60 parts of neem, 60 parts of arborvitae leaves, 60 parts of mint, 60 parts of lettuce, 60 parts of onion, 60 parts of mugwort leaves, 60 parts of bitter beans, 40 parts of fruit pomace, 32 parts of earthworm powder, fulvic acid 24 parts, 8 parts yeast, 4 parts boron, 4 parts bentonite, 4 pa...

Embodiment 2

[0066] A taro controlled-release fertilizer, which comprises the following raw materials in parts by weight: 90 parts of wrapping materials and 150 parts of fertilizer granules;

[0067] The wrapping material includes the following raw materials in parts by weight: 81 parts of fatty acid amide, 2.3 parts of ammonium phosphate, 2.3 parts of potassium nitrate, 2 parts of zinc nitrate, 0.4 part of calcium borate, 0.4 part of ferric chloride, and 0.4 part of zinc chloride , 0.4 parts of manganese chloride, 0.4 parts of copper chloride, 0.4 parts of sodium polyacrylate;

[0068] The fertilizer granules are in parts by weight and include the following raw materials:

[0069] 15 parts of aconitum, 15 parts of neem, 15 parts of arborvitae leaves, 15 parts of mint, 15 parts of lettuce, 15 parts of onion, 15 parts of mugwort leaves, 15 parts of bitter beans, 10 parts of dried bagasse, 8 parts of earthworm powder, fulvic acid 6 parts, 2 parts of enzyme bacteria, 0.5 parts of boron eleme...

Embodiment 3

[0075] A taro controlled-release fertilizer, which comprises the following raw materials in parts by weight: 60 parts of wrapping materials and 350 parts of fertilizer granules;

[0076] The wrapping material is in parts by weight and includes the following raw materials: 54 parts of fatty acid amide, 1.5 parts of ammonium phosphate, 1.5 parts of potassium nitrate, 1.4 parts of zinc nitrate, 0.3 part of calcium borate, 0.3 part of ferric chloride, and 0.3 part of zinc chloride , 0.2 part of manganese chloride, 0.2 part of copper chloride, 0.1 part of potassium polyacrylate, 0.1 part of ammonium polyacrylate, 0.1 part of starch grafted sodium acrylate;

[0077] The fertilizer granules are in parts by weight and include the following raw materials:

[0078] 35 parts of aconitum, 35 parts of neem, 35 parts of arborvitae leaves, 35 parts of mint, 35 parts of lettuce, 35 parts of onion, 35 parts of mugwort leaves, 35 parts of bitter beans, 5 parts of edible mushroom residue, 5 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com