Reusable Hydroxypropyl Guarin Fracturing Fluid

A technology of hydroxypropyl guar gum and fracturing fluid, applied in the field of chemicals, can solve the problem of inability to match the properties of hydroxypropyl guar gum cross-linking, save chemical raw materials, reduce fracturing costs, and protect the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

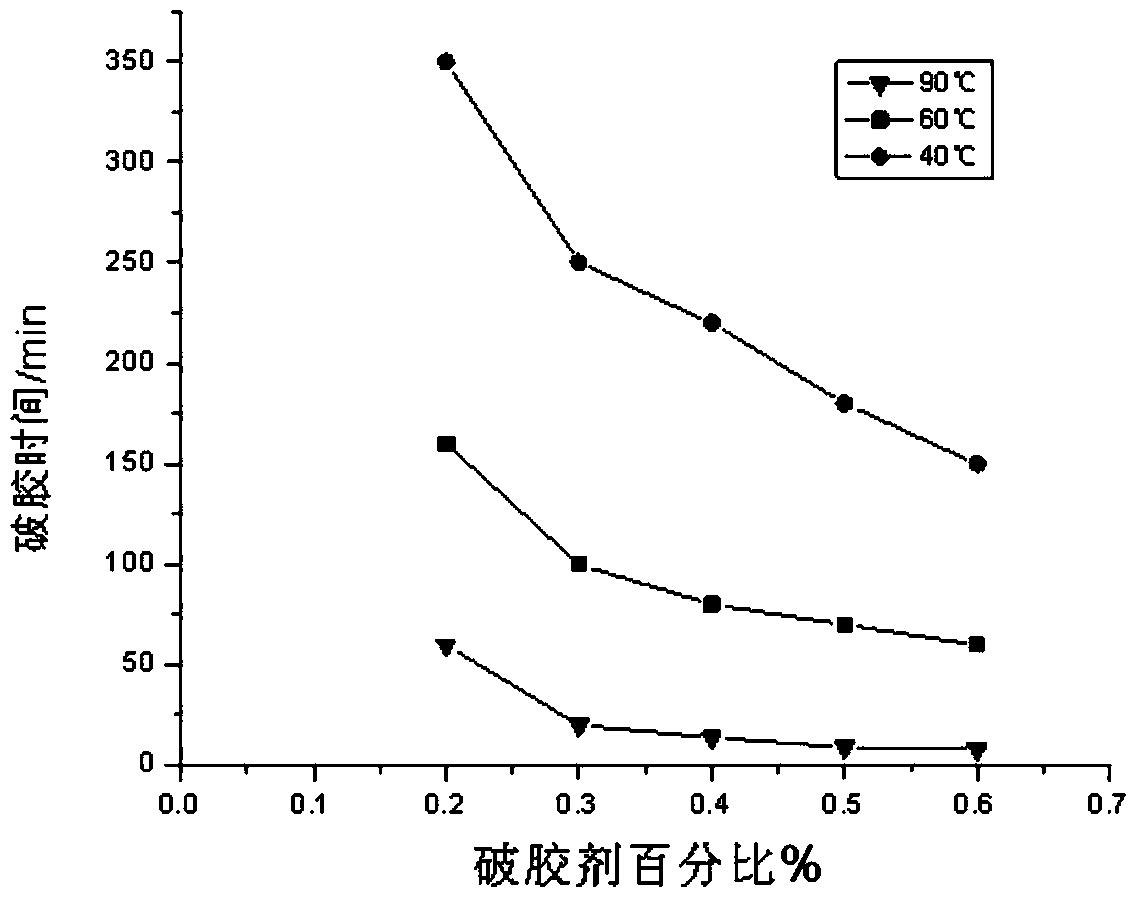

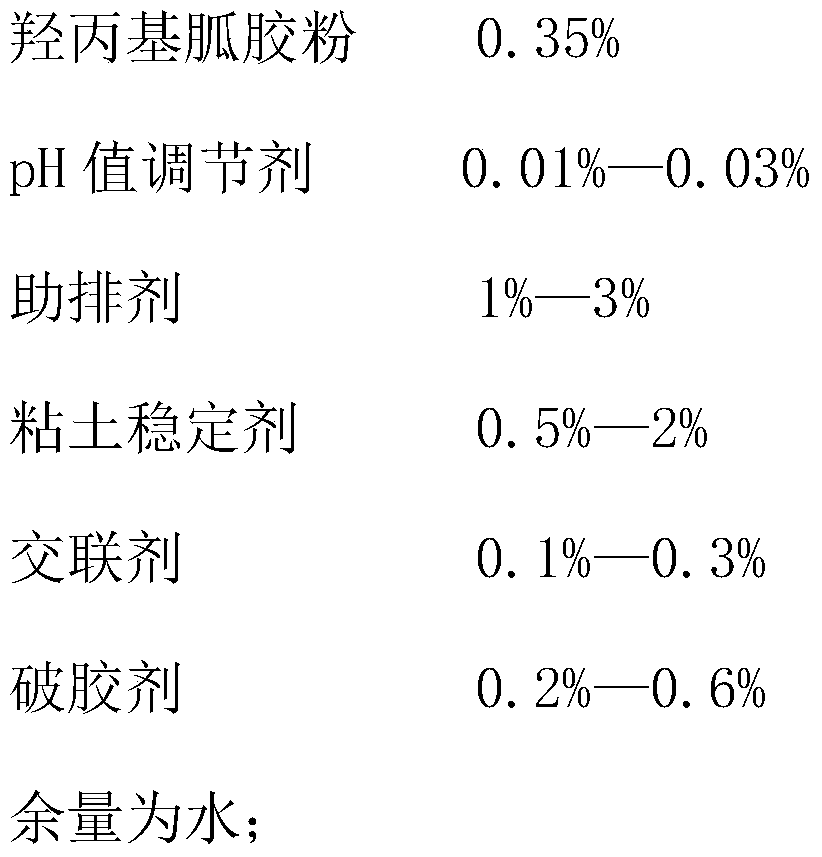

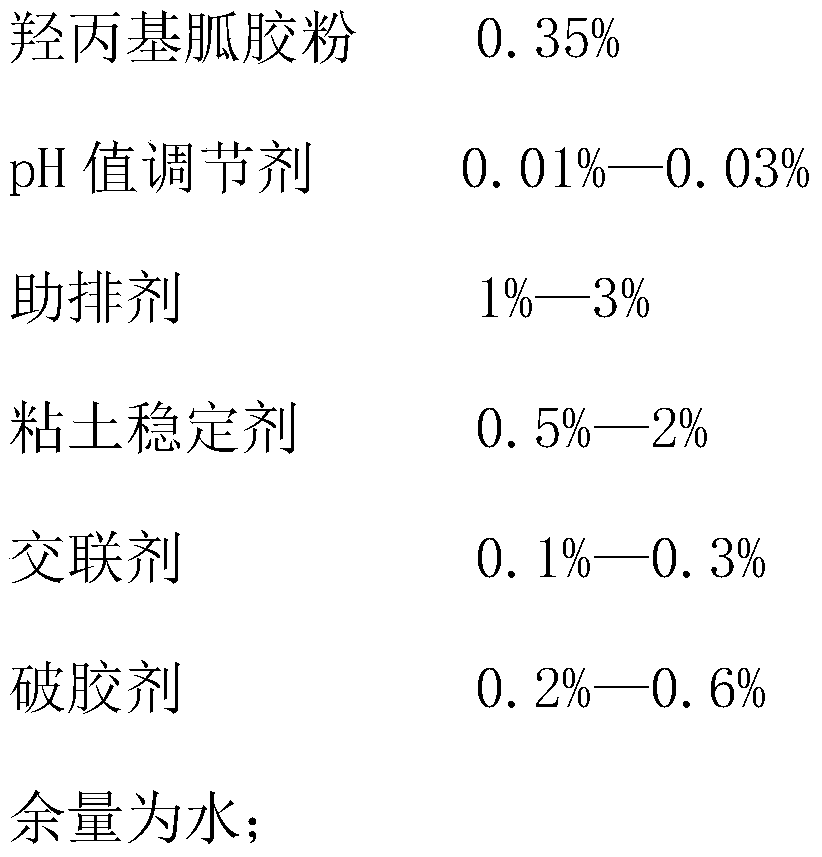

[0026] When in use, prepare 0.35% hydroxypropyl guar gum aqueous solution, add additives such as 0.03% pH regulator, 3% drainage aid, 2% clay stabilizer after being fully swollen, with 0.3% borax as cross-linking agent, form can After hanging the jelly, add 0.5% gel breaker ammonium oxalate and paraformaldehyde, the mass ratio of the two is 2:1, the viscosity will drop to 40mPa·s and the pH value will drop to 7 after 3 hours at 40°C. On this basis, continue to add additives, adjust the pH to 9-10 and add a cross-linking agent to still form a pickable jelly, so the flowback liquid can be reused. If the fracturing fluid is not recycled, its final viscosity can be reduced to 5mPa·s, and the gel can be completely hydrated and broken.

Embodiment 2

[0028] When in use, prepare 0.35% hydroxypropyl guar gum aqueous solution, add additives such as 0.03% pH regulator, 3% drainage aid, 2% clay stabilizer after being fully swollen, with 0.3% borax as cross-linking agent, form can After hanging the jelly, add 0.5% gel breaker ammonium acetate and paraformaldehyde, the mass ratio of the two is 2:1, the viscosity will drop to 40mPa·s and the pH value will drop to 7 after 3 hours at 40°C. On this basis, continue to add additives, adjust the pH to 9-10 and add a cross-linking agent to still form a pickable jelly, so the flowback liquid can be reused. If the fracturing fluid is not recycled, its final viscosity can be reduced to 5mPa·s, and the gel can be completely hydrated and broken.

Embodiment 3

[0030] When in use, prepare 0.35% hydroxypropyl guar gum aqueous solution, add additives such as 0.02% pH regulator, 2% drainage aid, 1% clay stabilizer after being fully swollen, with 0.2% borax as crosslinking agent, form can After hanging the jelly, add 0.3% gel breaker ammonium oxalate and paraformaldehyde, the mass ratio of the two is 2:1, the viscosity will drop to 40mPa·s and the pH value will drop to 7 after 100min at 60°C. On this basis, continue to add additives, adjust the pH to 9-10 and add a cross-linking agent to still form a pickable jelly, so the flowback liquid can be reused. If the fracturing fluid is not recycled, its final viscosity can be reduced to 5mPa·s, and the gel can be completely hydrated and broken.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com