Method for replacing primary hydrogenation catalyst in coke oven gas to methanol unit

A hydrogenation catalyst, coke oven gas technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the irreversible poisoning of methanol synthesis catalysts and reduce the start of equipment. In order to achieve good organic sulfur conversion efficiency, improve the operating rate of the device, and reduce the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

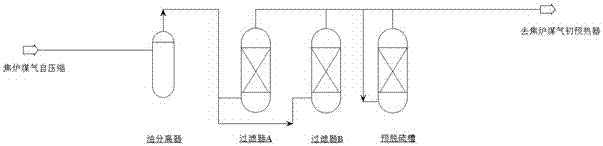

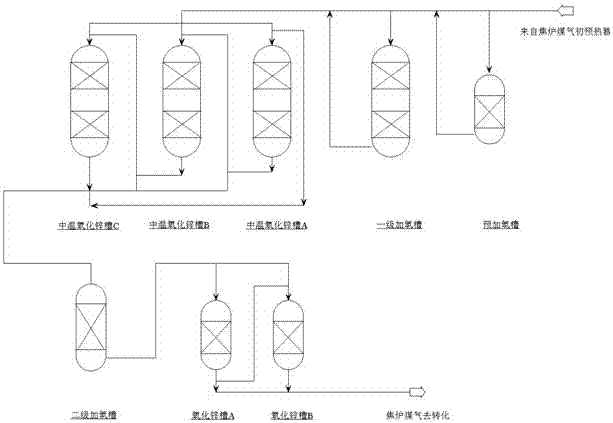

[0020] Embodiment: Taking this method as an example in a 200,000-ton / year coke oven gas methanol system, the filling capacity of the pre-hydrogenation tank is 5m 3 , the gas volume is 30000NM 3 / h, so the airspeed is 6000NM 3 / (h·m 3 ), the organic sulfur conversion rate of the hydrogenation catalyst is about 60% at this space velocity. The organic sulfur loading capacity of the iron-manganese desulfurization catalyst is 52m 3 , the conversion rate of organic sulfur is 80%. The upper part of the zinc oxide tank A is equipped with 5m 3 , so the organic sulfur conversion rate is also 60%. The filling capacity of the secondary hydrogenation tank is 17m 3 , the gas volume is 30000NM 3 / h, so the airspeed is 1768NM 3 / (h·m 3 ), the organic sulfur conversion rate of hydrogenation catalyst under this space velocity is 90%. The organic sulfur content in the fine desulfurization inlet gas is about 150mg / m3 3 , after cutting out the first-stage hydrogenation catalyst, use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com