Equipment and method for pre-processing fabric in cylinder

A pretreatment and fabric technology, applied in the textile industry, can solve the problems of reducing production efficiency and economic benefits, wasting manpower and time, and high professional labor, and achieving the effect of shortening dyeing time, reducing folding repetition, and reducing expenditure costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution described in the application of the present invention will be described in a non-restrictive manner below in conjunction with the accompanying drawings and embodiments, in order to provide the public with a better understanding of the technical solution, rather than to limit the technical solution.

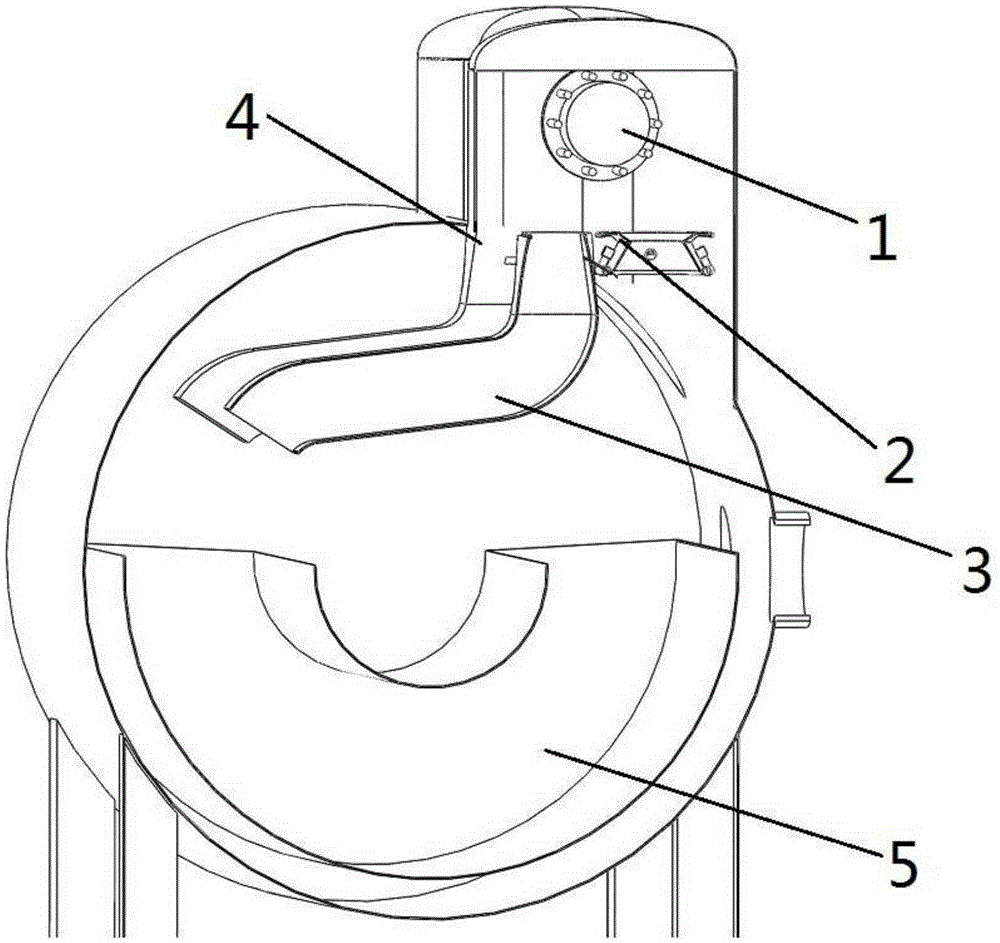

[0024] figure 1 The position of each mechanical structure of the dyeing machine is shown. The fabric passes through the cloth storage tank 5 and is lifted upwards by the drum 1. After passing through the steam injection device 2 in the application of the present invention, it passes through the drum 1 and falls downward under the action of gravity. 4, then enter the swing bucket 3, then fall back into the cloth storage tank 5, and so on.

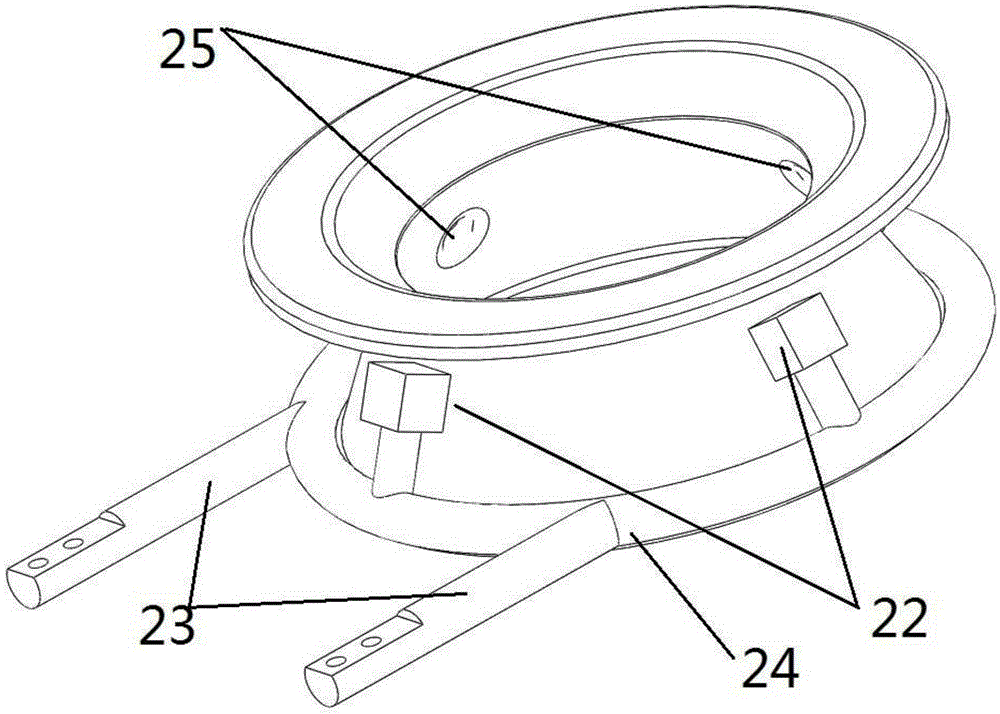

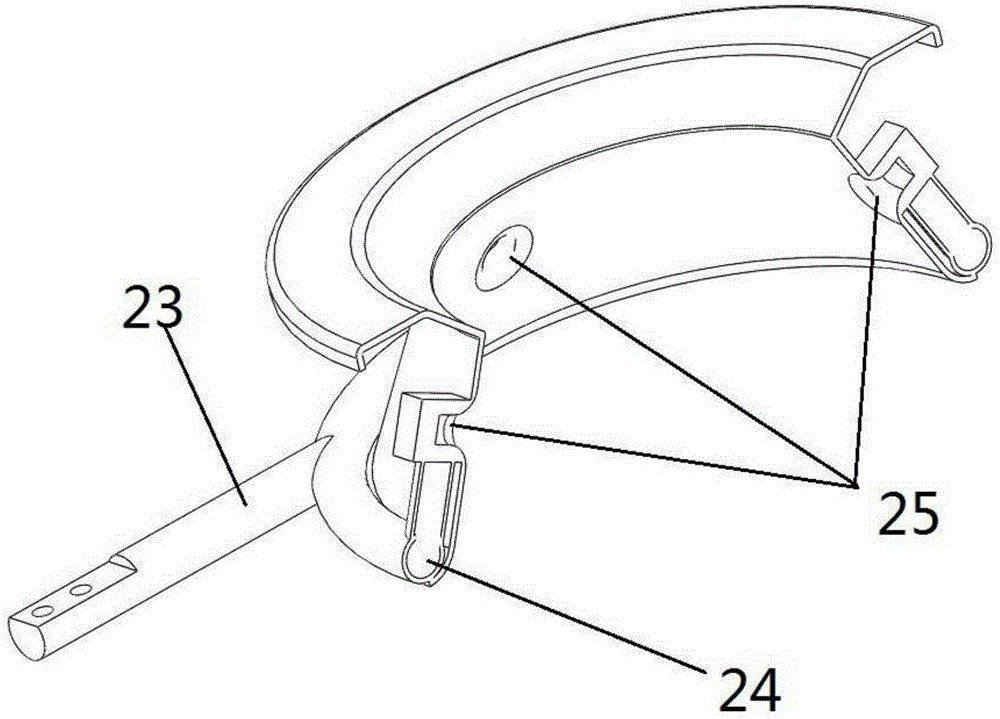

[0025] like Figure 2-3 As shown, it is a schematic structural view of the steam injection device 2 in the device for pretreating the fabric in the cylinder according to the application of the present invention. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com