Suction type spud shoe suitable for self-elevating platform and installation method

A suction-type, self-lifting technology, applied to sheet pile walls, water conservancy projects, artificial islands, etc., can solve problems such as high risk and high power consumption, and achieve the effects of increasing bearing capacity, simplifying installation, and reducing the difficulty of pulling out piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

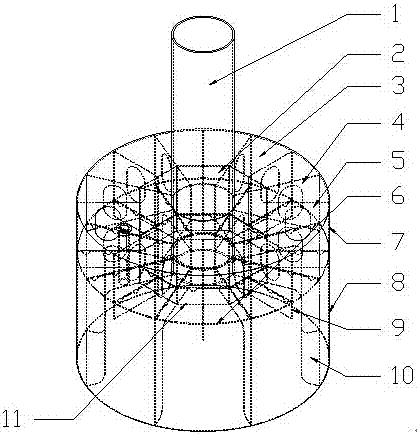

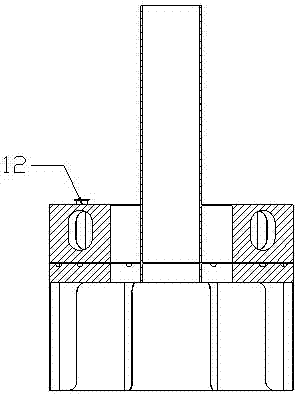

[0026] like Figure 1-2 As shown, the present invention includes a top cover plate 3, a main rib plate 4, a rib plate 5, an upper transverse plate 2, an upper peripheral plate 7, a lower bearing plate 6, a main rib plate 10 of the skirt plate, a rib plate 9 of the skirt plate, and a lower transverse plate Plate 11, lower peripheral skirt plate 8 and drainage pipe 12, the top cover plate 3 is located on the upper part of the lower bearing plate 6, the center of the top cover plate 3 and the lower bearing plate 6 is provided with a central round hole, and the pile legs 1 pass through the top cover plate 3 The central round hole of the top cover plate 3 is welded and connected, and the pile leg 1 is welded and connected with the lower bearing plate 6 through the central round hole of the lower bearing plate 6; the top cover plate 3 and the lower bearing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com