Anti-outburst method for wire saw cutting seam area on coal seam floor

A technology of coal seam floor and wire saw, which is used in earth-moving drilling, gas discharge, safety devices, etc., can solve the problems of high cost of mining protective layer, affecting the safety of coal mines, replacement deployment, benefit, and long time, and the treatment time can be achieved. Control, excavation investment is small, the effect of increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

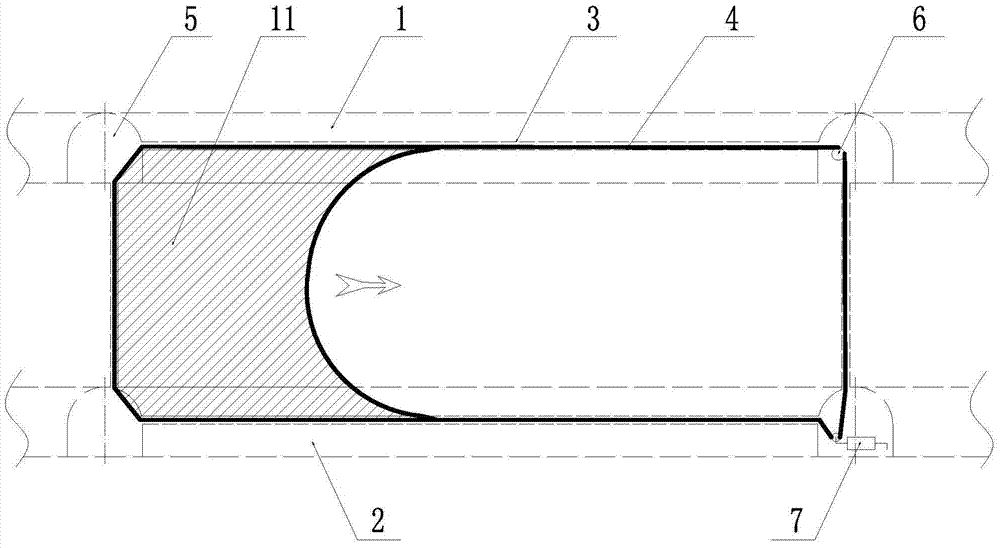

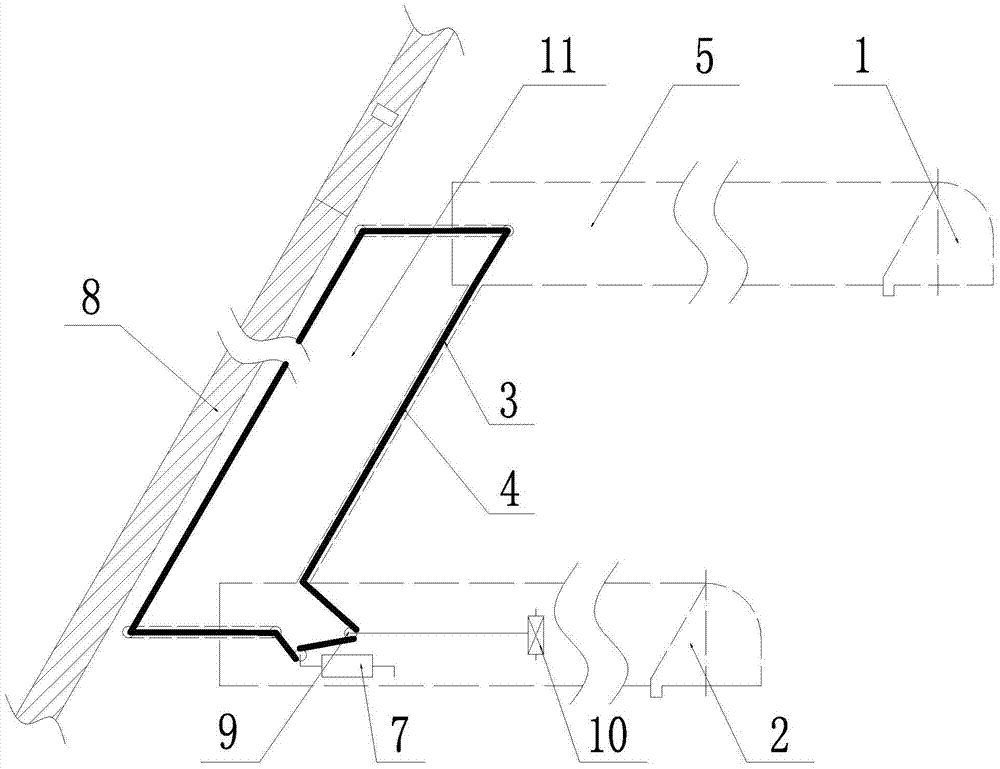

[0034] A method for preventing outbursts in the seam cutting area of a coal seam floor with a wire saw, using equipment including a 500m directional drilling rig and supporting equipment, a diamond wire saw, an endless rope winch, and the like.

[0035] Step 1. Ascertain the occurrence of coal seams

[0036] Conduct geological exploration into the coal seam in the drainage roadway, find out the occurrence of the coal seam, draw the contour map of the coal seam floor, compile the geological report, and provide basic parameters for the excavation of the stone gate and the construction of directional drilling.

[0037] Step 2. Digging into the Stone Gate

[0038] In the upper and lower drainage lanes with different elevations, two stone gates are dug into the coal seam respectively to form four parallel stone gates arranged in a quadrangular shape. The stone gates stop at a distance of 2m from the normal line of the coal seam floor and are well supported; The strike distance o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com