Quick cooling system

A fast, heat-exchanging cartridge technology, applied in fluid pressure actuation system components, fluid pressure actuation devices, servo meter circuits, etc., can solve problems such as unstable operation of hydraulic equipment, frequent failures of hydraulic equipment, and poor cooling effect. Achieve the effects of accelerating the cooling process, shortening the cooling processing time, and reducing cooling power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

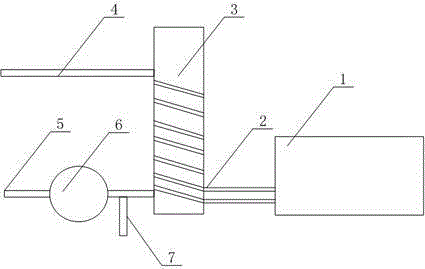

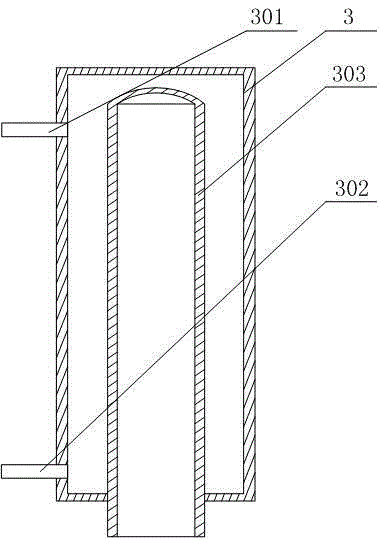

[0020] Such as figure 1 and figure 2 As shown, this embodiment includes a water tank 1 and a heat exchange cylinder 3, the upper and lower ends of the heat exchange cylinder 3 are respectively connected with a liquid outlet pipe 5 and a liquid return pipe 4, and the water tank 1 is connected with a heat exchange pipe 2, so The heat exchange tube 2 is spirally wound on the outer peripheral wall of the heat exchange cylinder 3 along the axial direction, and a hydraulic oil inlet 301 and a hydraulic oil outlet 302 communicating with the interior of the heat exchange cylinder 3 are opened on the same side wall, and also include Sleeve 303, the sleeve 303 runs through both ends of the heat exchange cylinder 3, the outer wall of the sleeve 303 and the inner wall of the heat exchange cylinder 3 are annular, and fans 304 are respectively installed at both ends of the sleeve 303 , the rotation directions of the two fans 304 are opposite. When the present invention works, the coolant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com