Response time calibration device of temperature sensor

A temperature sensor and response time technology, applied in the field of temperature sensor response time calibration, can solve the problems of low response time accuracy, unreliable response time, low calibration accuracy, etc., achieve reliable response time, ingenious design, and improve calibration The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

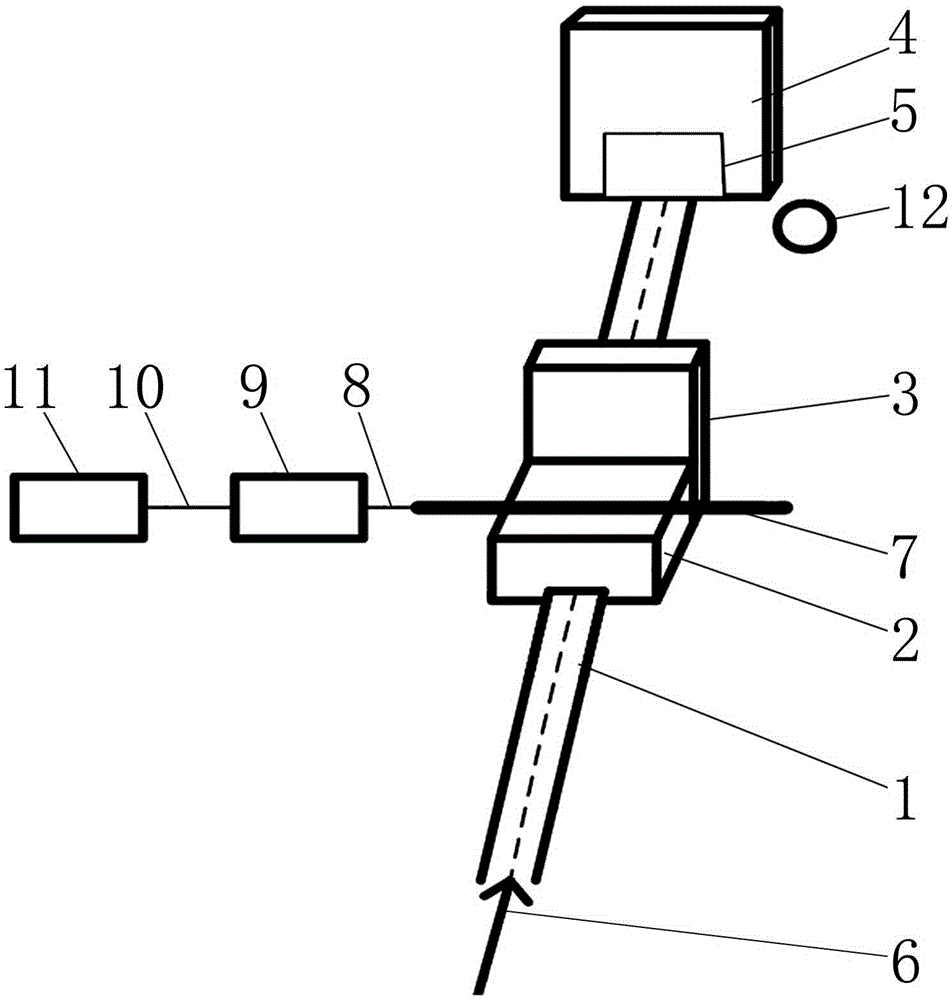

[0021] A response time calibration device for a temperature sensor, comprising a longitudinal linear guide rail 1, a slider with pulleys 2, a small vertical baffle 3, a large vertical baffle 4, a quick adsorption piece 5, a quick ejection device 6, and a temperature sensor 7 , compensation wire 8, signal acquisition and processing integrated circuit 9, data transmission line 10, data display device 11, flame temperature source 12;

[0022] Wherein, the slider 2 with a pulley is slidably installed on the longitudinal linear guide rail 1;

[0023] The lower part of the rear surface of the vertical small baffle plate 3 is fixed to the front surface of the slide block 2 with pulleys;

[0024] The middle part of the lower surface of the vertical large baffle 4 is fixed to the front part of the upper surface of the longitudinal linear guide rail 1, and the rear surface of the vertical large baffle 4 is parallel to the front surface of the vertical small baffle 3;

[0025] The numbe...

Embodiment 2

[0034] A response time calibration device for a temperature sensor, comprising a longitudinal linear guide rail 1, a slider with pulleys 2, a small vertical baffle 3, a large vertical baffle 4, a quick adsorption piece 5, a quick ejection device 6, and a temperature sensor 7 , compensation wire 8, signal acquisition and processing integrated circuit 9, data transmission line 10, data display device 11, flame temperature source 12;

[0035] Wherein, the slider 2 with a pulley is slidably installed on the longitudinal linear guide rail 1;

[0036]The lower part of the rear surface of the vertical small baffle plate 3 is fixed to the front surface of the slide block 2 with pulleys;

[0037] The middle part of the lower surface of the vertical large baffle 4 is fixed to the front part of the upper surface of the longitudinal linear guide rail 1, and the rear surface of the vertical large baffle 4 is parallel to the front surface of the vertical small baffle 3;

[0038] The number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com