Greenhouse labour-saving automatic following work platform based on somatosensory inductor

An automatic follow-up and sensor technology, applied in the direction of instruments, motor vehicles, non-electric variable control, etc., can solve the problems that rail transportation is not flexible enough, and is not suitable for the structural characteristics of greenhouses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but it does not represent the only embodiment of the present invention.

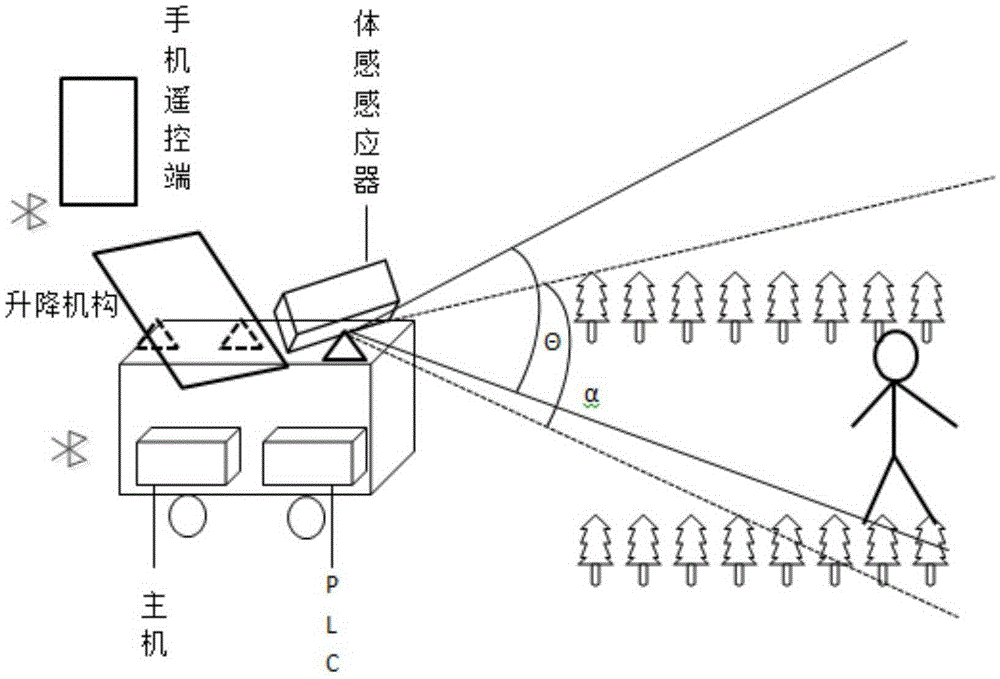

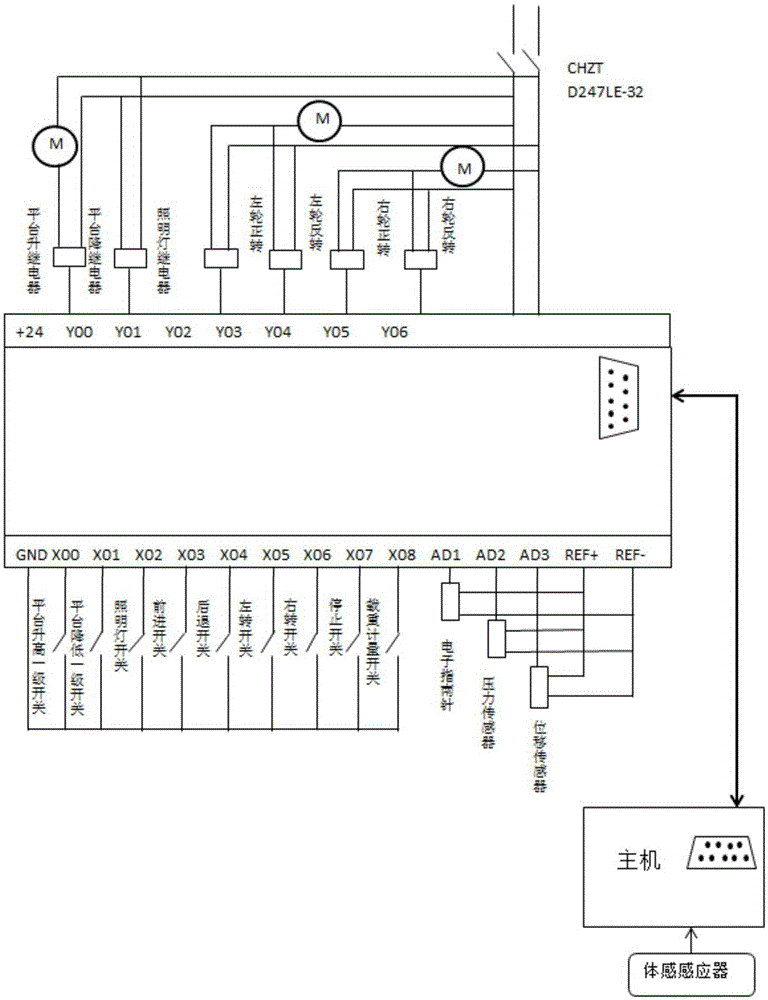

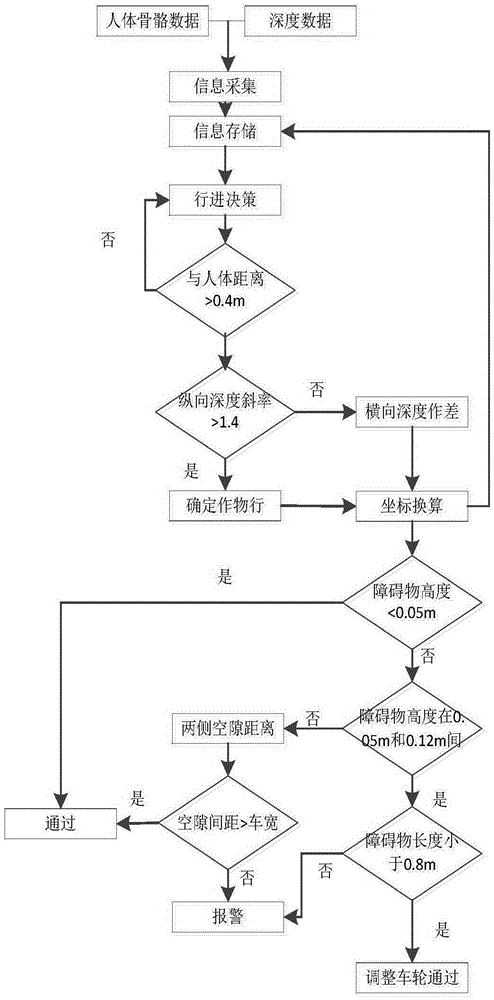

[0022] Please read figure 1 , The greenhouse labor-saving automatic following platform mainly includes six parts: image acquisition device, image processing and data processing module, labor-saving transportation platform controller, labor-saving transportation platform execution device, remote control device and auxiliary equipment. Among them, the image acquisition device, image processing and data processing modules, and the labor-saving transportation platform controller are all installed on the transportation platform.

[0023] (1) The image acquisition device is mainly a somatosensory sensor, which is connected to the host computer through the RS232 interface, and transmits the image data to the host computer.

[0024] (2) The image processing and data processing modules are mainly composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com