Remote control virtual training system of fully mechanized coal mining face

A fully-mechanized mining face and remote control technology, applied in the field of virtual simulation, can solve the problems of remote control system safety hazards, unclear images collected by cameras, and difficulty in manual intervention and decision-making, and achieve good interactivity and sense of reality, popularization and application High value, effect of improving quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

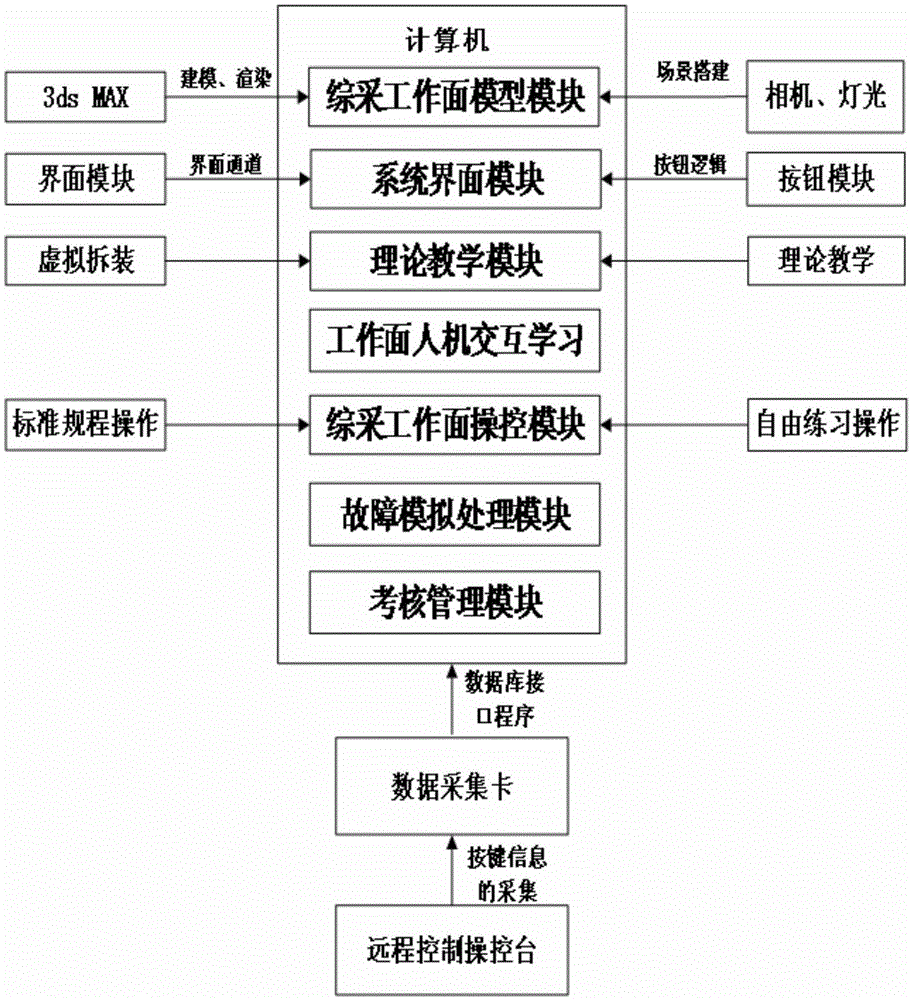

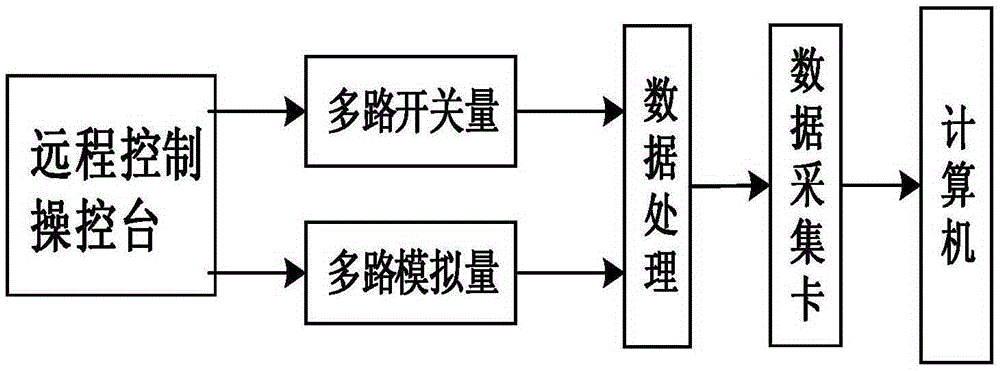

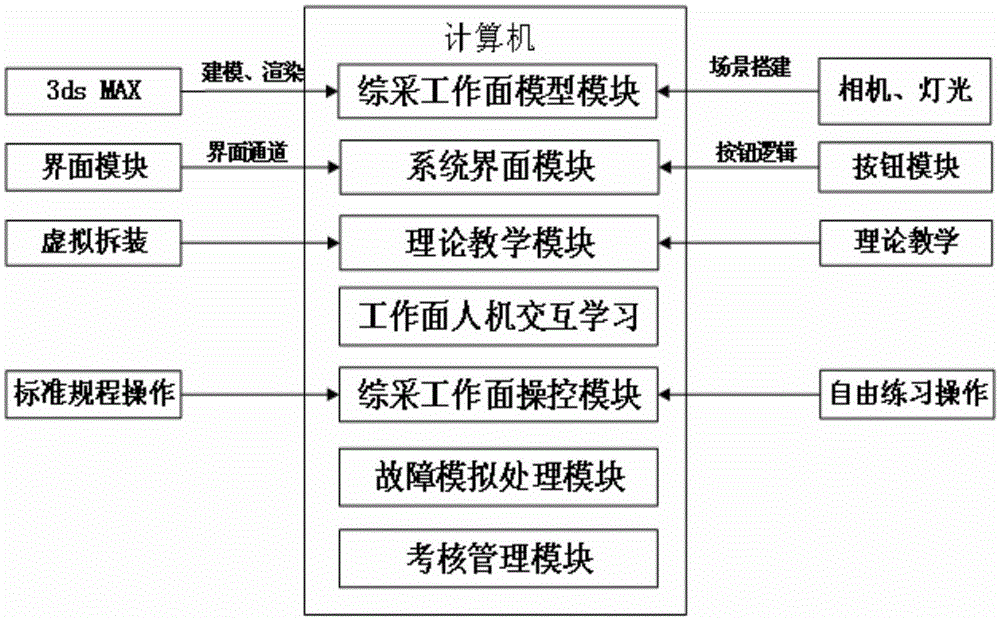

[0031] Such as figure 1 As shown, a remote control virtual training system for fully mechanized coal mining face, including hardware, software, and data interface. Hardware includes computers, data acquisition cards, control devices, and consoles. The control actions issued by the control devices (switches, handles, knobs) on the console are collected through the data acquisition card, and transmitted to the computer to complete the control of the virtual prototype. The software part includes fully mechanized mining face model module (shearer, hydraulic support, scraper conveyor, virtual scene), fully mechanized mining face training system interface module, fully mechanized mining face teaching module, fully mechanized mining face control module, assessment management module. Through this part, the operator can complete the theoretical and practical training of the three machines in the fully mechanized mining face, and improve the operator's ability to operate the equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com