Method for improving activity of nitrification function microbiology in activated sludge through feeding iron hydroxide during in situ preparation

A functional microorganism, ferric hydroxide technology, applied in the fields of ferric oxide/ferric hydroxide, chemical instruments and methods, sustainable biological treatment, etc., can solve problems such as poor operation stability, improve applicability, promote enzyme The effect of low secretion, investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

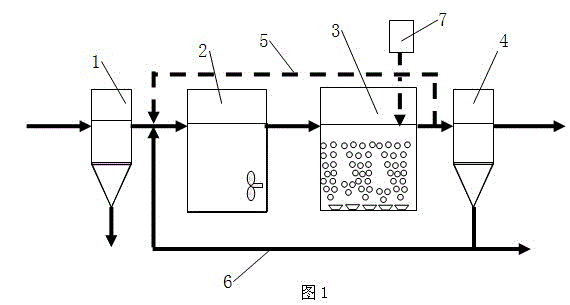

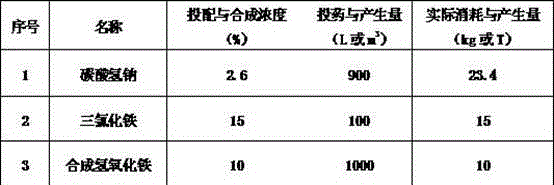

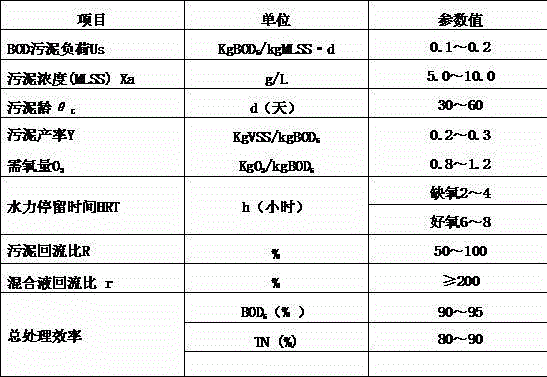

[0020] In the present invention, fresh unaged ferric hydroxide prepared on site is directly added to the aerobic pool of the sewage biological denitrification system, and the combination of ferric hydroxide flocs and activated sludge microbial flocs strengthens the ferric hydroxide Ions participate in electron transfer and enzymatic reaction activators, which not only effectively improve the metabolic activity of microbial biochemical reactions, but also improve and strengthen the floc structure of activated sludge, forming nitrification with high reactivity and floc stability. Functional activated sludge, the final activated sludge mixture is separated from mud and water in the secondary settling tank, and the separated activated sludge supernatant is further treated or discharged.

[0021] In the sewage biological denitrification system facilities (the sewage biological denitrification system refers to the sewage biological denitrification system in which the nitrifying micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com