Method of improving low-dielectric film thickness stability

A technology with thin film thickness and low dielectric properties, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as low film thickness, and achieve the effect of improving yield stability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the following technical solutions and technical features can be combined with each other.

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

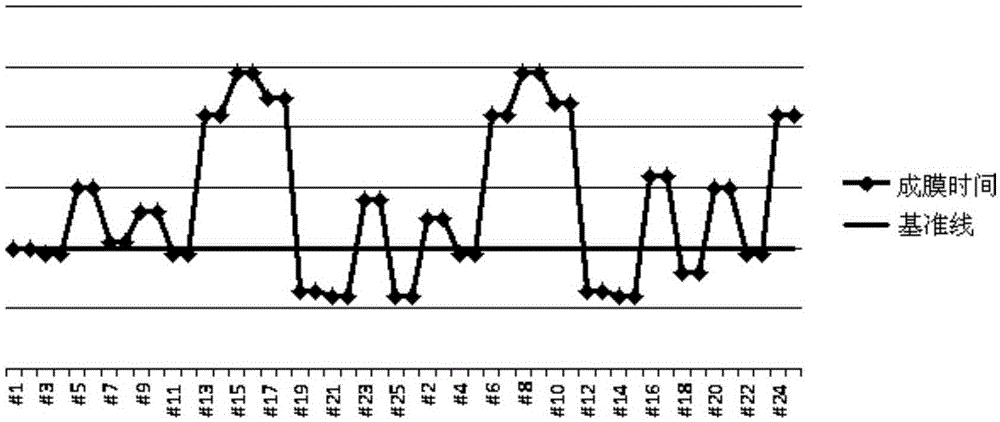

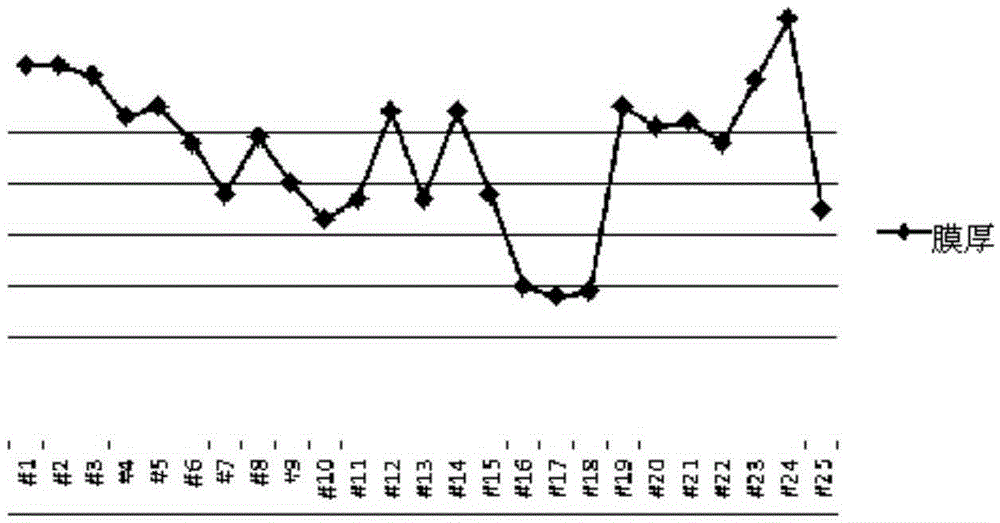

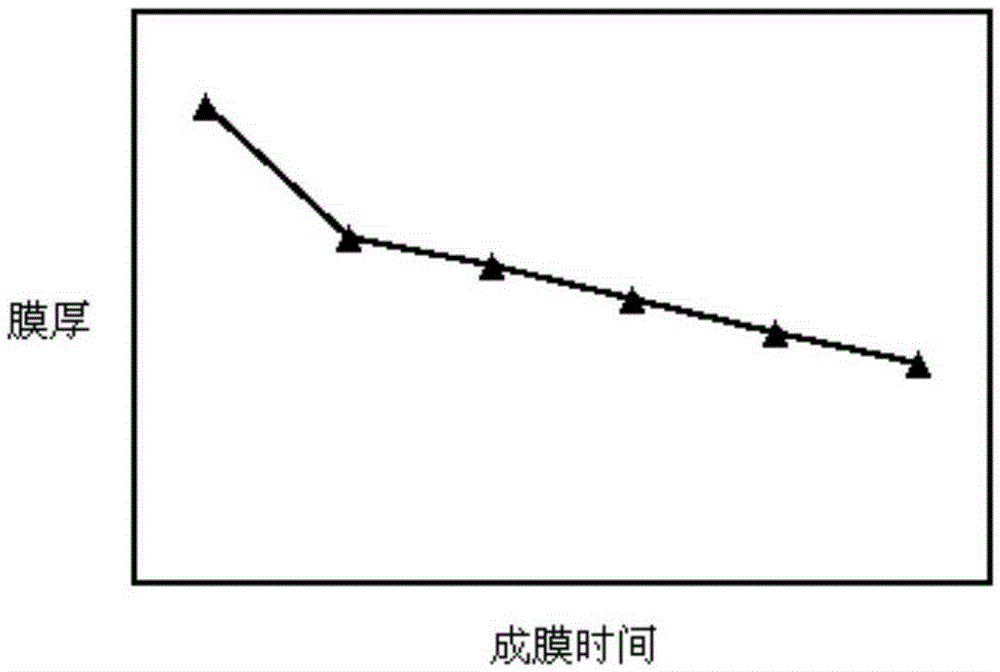

[0029] The invention mainly solves the problem of film thickness stability between transfers of low-kBD1 process silicon wafers in large-scale production. For the multi-silicon wafer film-forming process, when the wafer (wafer) is in continuous operation, the machine will enter a cycle. As the wafer process progresses, the hardware actions and process programs of the machine will be cycled. By collecting and analyzing the historical data of the operation, find out the cycle law of the film-forming pause time (completed film-forming time, idle time) and cleancount. For the wafers of the same cleancount, according to the idle time data (as long as the wafer continues to perform the process, the data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com