Connector device for arrangement-type pre-buried cable conduits capable of being randomly combined

A technology of cable pipe and joint device, which is applied in the direction of electrical components, etc., can solve the problems of template support trouble, influence on cable laying, cable pipe damage, etc., to save manpower and material resources, considerable economic benefits, and prevent cable accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0009] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

Embodiment

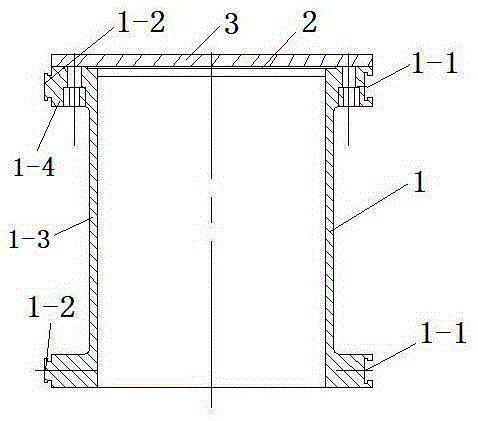

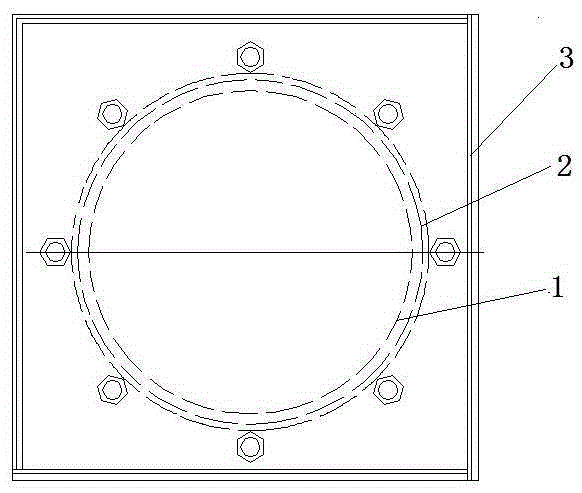

[0010] Embodiment: A kind of pre-buried cable pipe joint device that can be combined and arranged at will (see Figure 1-Figure 2 ), is a cable pipe joint device that can be pre-embedded in wells and tunnels in random combinations and arrangements. It is composed of at least one joint unit. It can use a single joint unit or at least two joint units. combined. Each joint unit is composed of a cable pipe joint 1, a rubber pad 2 and a cover plate 3. The cable pipe joint 1 is connected as a whole by the coil 1-3 and the plate mouth 1-4 connected to the two ends of the coil 1-3. Composition, the cable pipe joint 1 and the cover plate 3 are made of hard plastic, connected by bolts, and the rubber pad 2 is connected between the cable pipe joint 1 and the cover plate 3, which plays a waterproof role. The inner diameter of the cable pipe joint 1 is 170mm, which can be inserted into the cable pipe of CPVC167 / 7, and can also be inserted into the cable pipe of CGCT150 / 8 and MPP160 / 10. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com