A Hybrid Suspension Disc Non-contact Ultrasonic Motor

An ultrasonic motor, non-contact technology, used in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. Speed and life, simple structure, effect of reducing friction torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

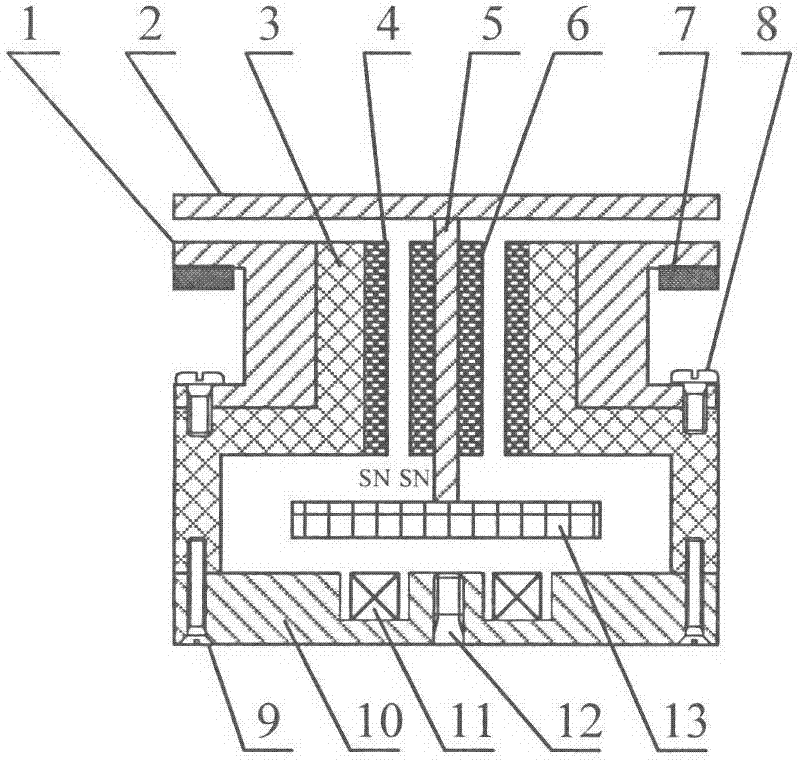

[0009] attached figure 1 It is a specific schematic block diagram of the structure of a hybrid suspension disc non-contact ultrasonic motor provided by the embodiment of the present invention. It is mainly based on the mixed suspension force of sound pressure, permanent magnetic force and electromagnetic force, and uses the motor rotation mode formed by the excitation of piezoelectric ceramics to develop a hybrid suspension disc non-contact ultrasonic motor. The system is mainly composed of the following parts: motor stator, motor rotor, radial bearing stator, radial bearing rotor, axial bearing stator, axial bearing rotor and support. It can be seen from the figure that the motor stator is composed of the motor stator base 1 and the piezoelectric ceramic 7. The motor stator base (1) is a circular sleeve structure, and its axial cross-sectional surface is I-shaped, and its inner ring surface is tightly sleeved on the support 3 On the outer surface of the upper boss, the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com