freezer

A refrigeration device and refrigerant technology, applied in subcoolers, refrigerators, refrigeration components, etc., can solve problems such as poor cooling and insufficient refrigerant, and achieve the effects of suppressing overfilling and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

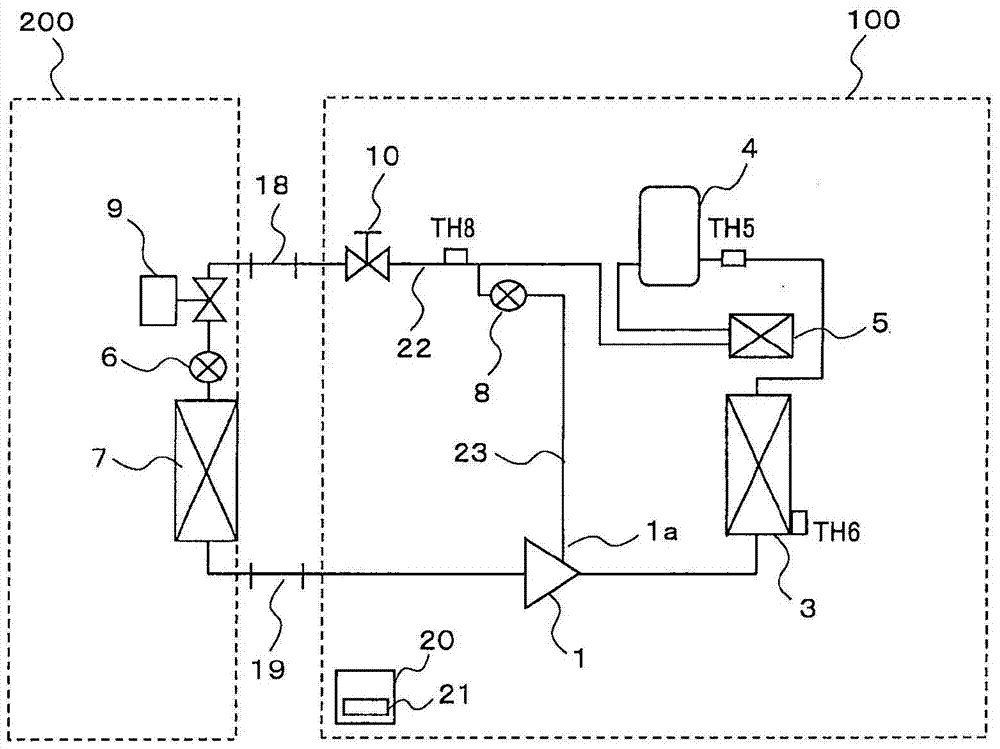

[0031] figure 1 It is a figure which shows an example of the refrigerant circuit of the refrigeration apparatus concerning Embodiment 1 of this invention.

[0032] The refrigeration system according to Embodiment 1 includes an outdoor unit 100 and an indoor unit 200 .

[0033] The outdoor unit 100 includes a compressor 1 , a condenser 3 , a liquid receiver 4 , and a subcooling heat exchanger 5 .

[0034] In addition, downstream of the subcooling heat exchanger 5, it is branched into a main flow path 22 going to the evaporator 7 of the indoor unit 200 and an injection flow path 23 going to the injection port 1a of the compressor 1, and a liquid operation is provided on the side of the main flow path 22. The valve 10 is provided with an expansion valve 8 on the side of the injection channel 23 . In addition, the indoor unit 200 is utilized by a showcase, a unit cooler, and the like.

[0035] The indoor unit 200 includes a liquid solenoid valve 9 , an expansion valve 6 , and ...

Embodiment approach 2

[0094] Figure 6 It is a figure which shows an example of the viewing windows 14 and 15 of the refrigeration apparatus concerning Embodiment 2 of this invention.

[0095] In addition, in this Embodiment 2, the difference with this Embodiment 1 is mainly demonstrated, and the same code|symbol is attached|subjected to the same part as this Embodiment 1, and description is abbreviate|omitted.

[0096] In Embodiment 2, a case will be described in which the refrigerant charge amount is confirmed by changing the position of the refrigerant liquid level 11 which is the largest throughout the year depending on the season, outside air temperature, high pressure, and the like.

[0097] In winter, etc., when the outside air temperature is low during the refrigerant charging operation, if the refrigerant is charged until the LED on the control board changes from N to O ( ) and the refrigerant liquid level 11 can be confirmed through the viewing window 14, the refrigerant may be charged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com