Cutting fluid filter device

A filter device and cutting fluid technology, applied in the direction of filtration separation, mobile filter element filter, adsorption water/sewage treatment, etc., can solve the problems of affecting the filtering effect of the filter, reducing the utilization rate of cutting fluid, and clogging the mesh of the filter. , to improve the filtration effect, promote flow and filtration, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

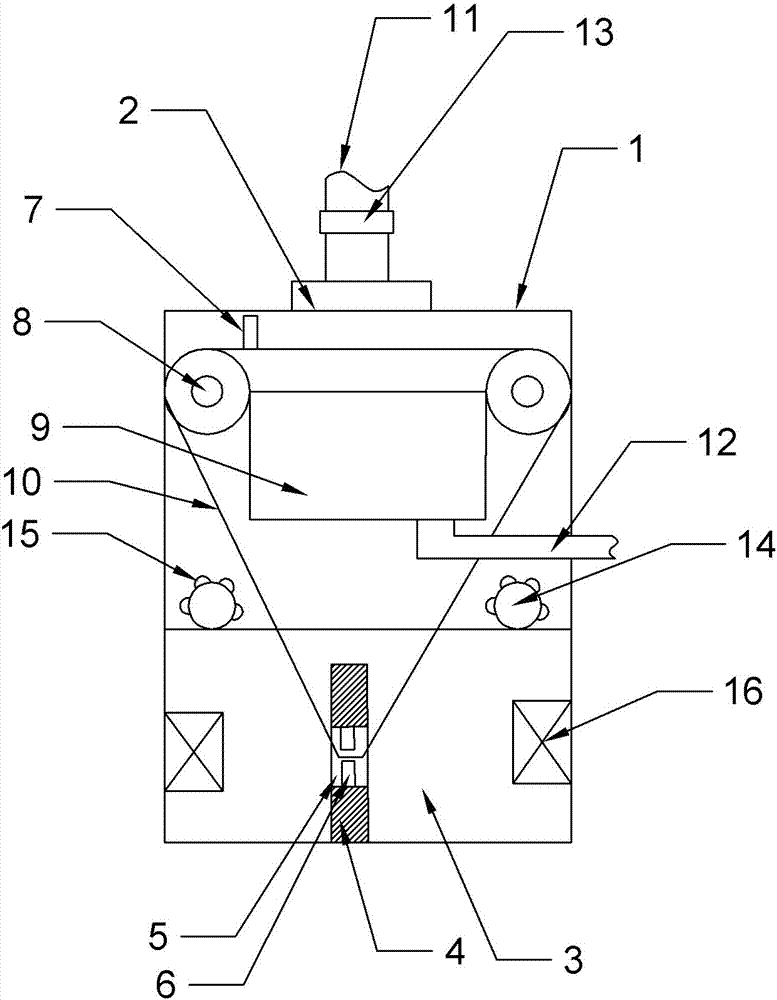

[0014] Such as figure 1 As shown, the cutting fluid filtering device includes a casing 1, a filtering mechanism and a cleaning mechanism. The filtering mechanism is located in the casing 1, the cleaning mechanism is located below the filtering mechanism, and the upper end of the casing 1 is provided with a feed port 2. The cleaning mechanism includes a cleaning tank 3 and a cleaning block 4. The cleaning block 4 is vertically arranged at the bottom of the cleaning tank 3. A through hole 5 in a horizontal direction is provided in the middle of the cleaning block 4. A scraper 6 is arranged on the upper and lower surfaces of the through hole 5 to clean. Adsorption balls 14 are arranged on the liquid surface of the tank 3, and protrusions 15 are arranged on the surface of the adsorption balls 14. Adsorption blades 16 are arranged on both side walls below the liquid level of the cleaning tank 3 , and a rotating shaft is arranged in the middle of the adsorption blades 16 , and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com